- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

10L to 3000L or more, can be customized

-

Weight (KG):

-

600 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SPX

-

Voltage:

-

220V/380v 50hz

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

27 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Cosmetic Cream Processing Plant

-

Heating method:

-

Electric heating or steam heating

-

Homogenizer:

-

Upper or lower homogenizer

-

Usage:

-

Mixing paste proucts

-

Design:

-

Can be customized, with control box

-

Function:

-

Mixing, heating and homogenizing

-

Control pannel:

-

Button type or PLC controller

-

Structure:

-

Main machine, water and oil pot,platform,stairs

Quick Details

-

Barrel Volume (L):

-

300

-

Max. Loading Volume (L):

-

360 L

-

Range of Spindle Speed(r.p.m):

-

0 - 3000 r.p.m

-

Max. Loading Capacity:

-

10L to 3000L or more, can be customized

-

Weight (KG):

-

600 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SPX

-

Voltage:

-

220V/380v 50hz

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

27 kW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Cosmetic Cream Processing Plant

-

Heating method:

-

Electric heating or steam heating

-

Homogenizer:

-

Upper or lower homogenizer

-

Usage:

-

Mixing paste proucts

-

Design:

-

Can be customized, with control box

-

Function:

-

Mixing, heating and homogenizing

-

Control pannel:

-

Button type or PLC controller

-

Structure:

-

Main machine, water and oil pot,platform,stairs

Product Description

|

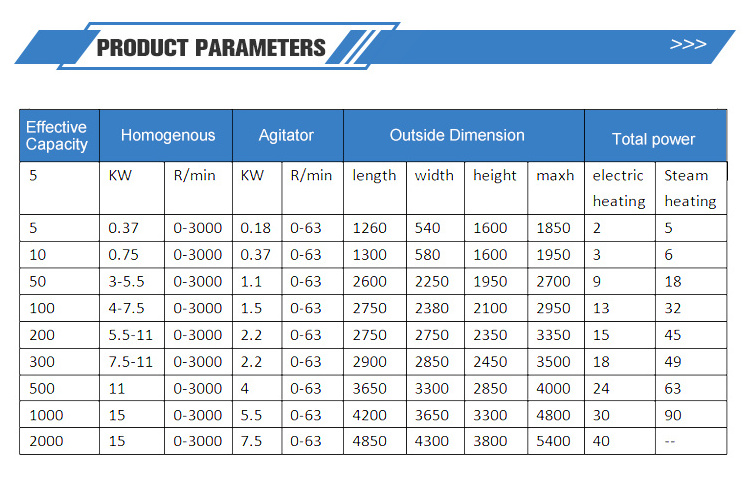

The Cosmetic Cream Processing Plant Parameter

|

|

|

||

|

Capacity

|

Emulsify

|

Stirrer

|

||

|

5L

|

0.37kw, 0-3500r/min

|

0.37kw ,10-70r/min

|

||

|

20L

|

2.2kw, 0-3500r/min

|

0.37kw ,10-70r/min

|

||

|

50L

|

3kw, 0-3500r/min

|

0.75kw ,10-70r/min

|

||

|

100L

|

3kw, 0-3500r/min

|

1.5kw ,10-70r/min

|

||

|

150L

|

4kw, 0-3500r/min

|

1.5kw ,10-70r/min

|

||

|

200L

|

5.5kw, 0-3500r/min

|

1.5kw ,10-70r/min

|

||

|

350L

|

7.5kw, 0-3500r/min

|

2.2kw ,10-70r/min

|

||

|

500L

|

7.5kw, 0-3500r/min

|

2.2kw ,10-70r/min

|

||

|

750L

|

11kw, 0-3500r/min

|

4kw ,10-70r/min

|

||

|

1000L

|

11kw, 0-3500r/min

|

4kw ,10-70r/min

|

||

|

2000L

|

15kw, 0-3500r/min

|

7.5kw ,10-70r/min

|

||

1. High-efficiency homogenizer: it adopts Germany combined six-layers shearing teeth structure, which gets dozens of times of emulsification effect every time the homogenizer shears the material.

2. Going up & down type homogenizing emulsifier: Suitable to mix many kinds of materials. Without a dead corner, leaving no materials in the tank after discharge. Homogenizer can work a long time continuously. It is the best emulsifier ever.

3. Material suction and discharge function: it can be fed materials from upside and downside, or separately. Long-distance conveying function, to avoid the final products being polluted.

4. Material suction from the bottom: unique powder suction function by one-button control, to ensure the powder homogenize and emulsify evenly.

5. All-wave, no dead corner, choked flow, stirring system: it increases the stirring speed and mixing effect.

6. Parameter record function: the historical record can be checked, conforms to GMP and ISO standard.

Mixing paddle

1. The stirring paddle is equipped with teflon plastic for better scraping materials along the wall

2.Used for mixing material, prevent material and pot wall uneven fusion, adjustable up and down, easy to clean the pot body

Homogenizer

Frequency conversion speed regulation, up to 3600 RPM, can accelerate the melting material, make the mixing material more uniform, more delicate..

How to Order Our Cosmetic Cream Processing Plant?

1. Customers offer the general design of the product.

2. Our designer will make a professional drawing according to your product layout.

3. After your confirmation of the drawings, inform us of the material and types you need.

4. We will do a quote once get the confirmation from you.

5. Note: Customers can order all product samples we put or you can also have your own idea, as we are a custom-made product suppliers, so different types are available.

Related Products

Hot Searches