- Product Details

- {{item.text}}

Quick Details

-

Power:

-

4 KW

-

Dimension(L*W*H):

-

185*125*150cm

-

Weight:

-

1400

-

Keywords:

-

nail screw thread rolling machine

-

Product name:

-

screw threading machine

-

produce style:

-

Factory produce directly

-

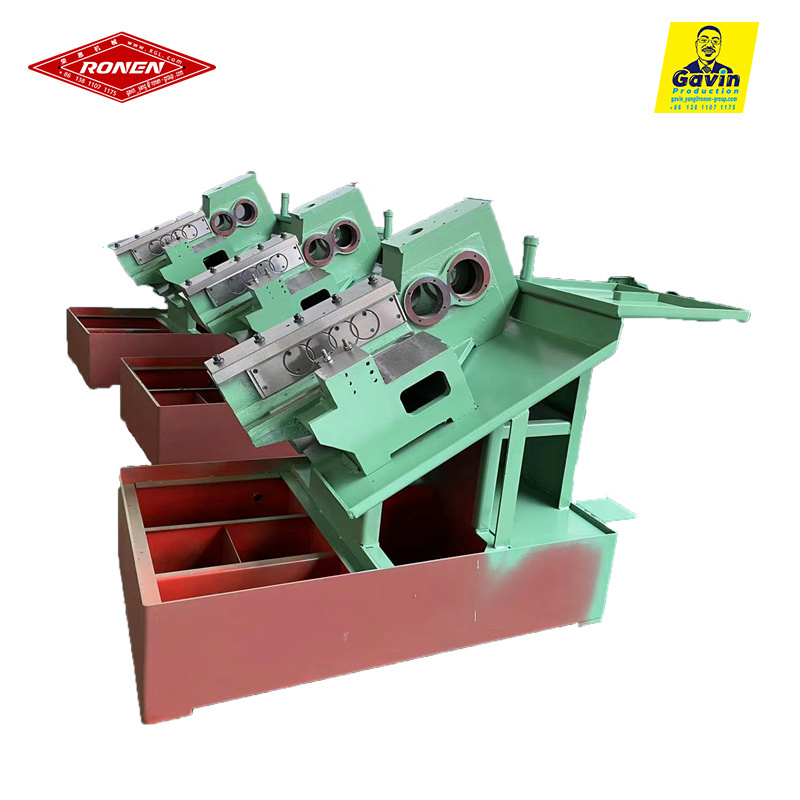

Color:

-

green

-

Raw material:

-

steel low carbon, stainless steel

-

After Warranty Service::

-

Video technical support, Online support,Spare parts...

-

MOQ:

-

1

-

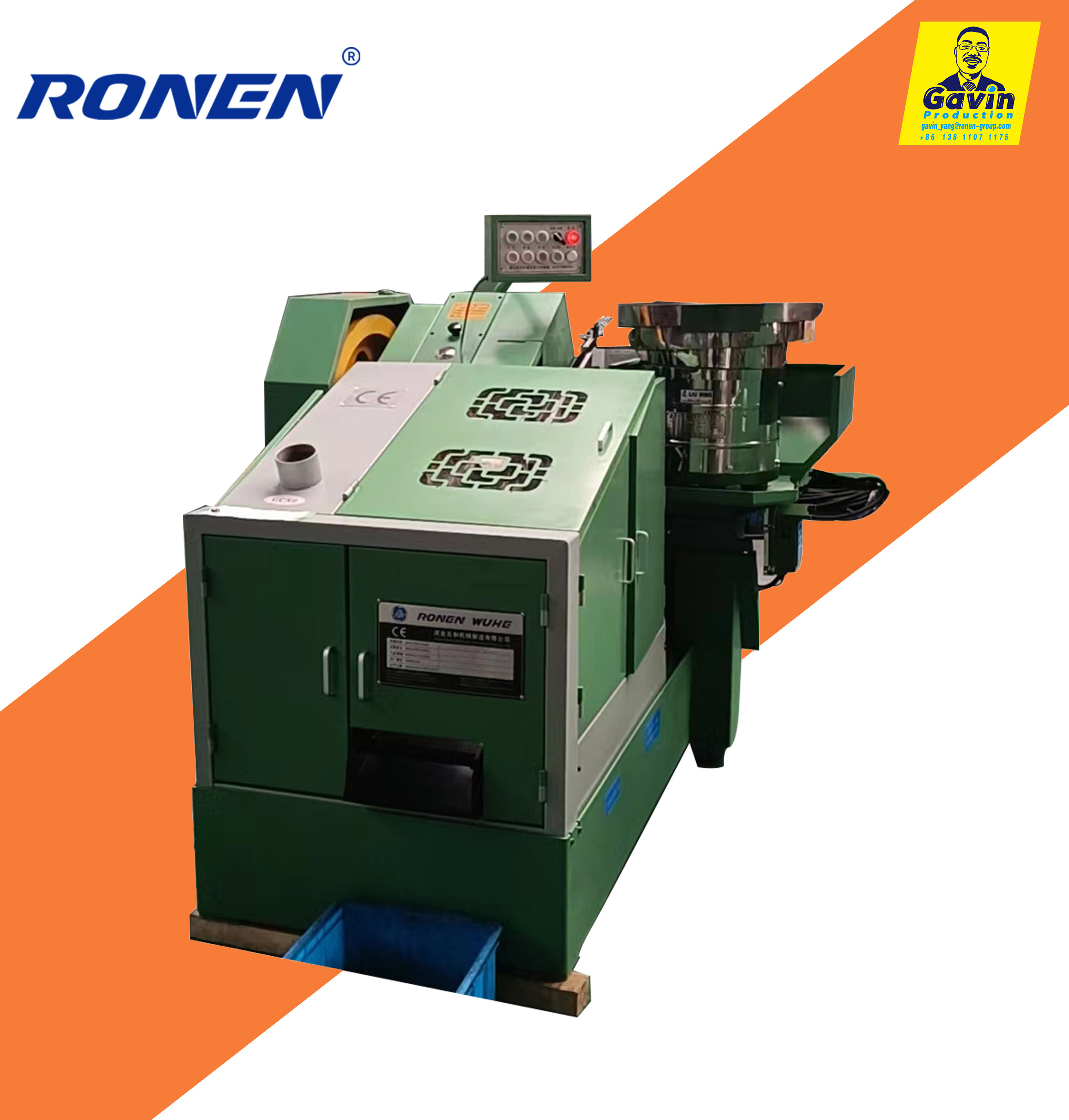

Type:

-

Fully Automatic

-

Packing:

-

Plastic Bags + Cartons + Pallet/Customized

-

Function:

-

automatic feeding and assembly screw/nut and washer

Quick Details

-

Place of Origin:

-

Hebei, China

-

Production Capacity:

-

120-160 pcs/min.

-

Brand Name:

-

Ronen Wuhe

-

Power:

-

4 KW

-

Dimension(L*W*H):

-

185*125*150cm

-

Weight:

-

1400

-

Keywords:

-

nail screw thread rolling machine

-

Product name:

-

screw threading machine

-

produce style:

-

Factory produce directly

-

Color:

-

green

-

Raw material:

-

steel low carbon, stainless steel

-

After Warranty Service::

-

Video technical support, Online support,Spare parts...

-

MOQ:

-

1

-

Type:

-

Fully Automatic

-

Packing:

-

Plastic Bags + Cartons + Pallet/Customized

-

Function:

-

automatic feeding and assembly screw/nut and washer

PRDUCT DESCRIPTION

Introduction

1.This thread rolling machine is mainly used for processing precision standard parts of external thread and high strength, including regular thread, trapezoid thread and modulus thread.

2.The objective material to be processed including carbon steel, alloy steel and nonferrous metal with elongation over 10% andtensile strength less than 100kg/mm².

3. Main functions of thread rolling machine make products happen plastic deformation by pressing of two dynamic and statics screw plates, and form the thread needed, it can accurately grinding various standard thread tooth of national standard,ISO,DIN, JIS, ANSI, BS,GB,etc., the machine has the advantages of rapid speed and good stability, the minute capacity can be up to about 300pcs, it is advanced thread machine with higher speed in the current market, which is suitable for mass production in the large scope thread factory. It can also design, coil abnormal screw and abnormal hardware and metal products especially according to the customers’ requirements.

2.The objective material to be processed including carbon steel, alloy steel and nonferrous metal with elongation over 10% andtensile strength less than 100kg/mm².

3. Main functions of thread rolling machine make products happen plastic deformation by pressing of two dynamic and statics screw plates, and form the thread needed, it can accurately grinding various standard thread tooth of national standard,ISO,DIN, JIS, ANSI, BS,GB,etc., the machine has the advantages of rapid speed and good stability, the minute capacity can be up to about 300pcs, it is advanced thread machine with higher speed in the current market, which is suitable for mass production in the large scope thread factory. It can also design, coil abnormal screw and abnormal hardware and metal products especially according to the customers’ requirements.

Characters

1.Machine tool use steel welding,through finish machining.

2.Rolling wheel adopt hard alloy material.

3.Sliding parts after manual grinding,improve the machining precision.

4.Small size,efficient,low noise.

5.Use high quality motor,make the machine perfect.

6.Power distribution box use high quality gear which through high frequency quenching,make the machine durable.

7.Distribution gear use the hollow design,make no longer restricted the length of the screw,the length of screw is unlimited in

theory.

8.Use Time Relay,reduce the labour,make the screw thread have a high consistency.

2.Rolling wheel adopt hard alloy material.

3.Sliding parts after manual grinding,improve the machining precision.

4.Small size,efficient,low noise.

5.Use high quality motor,make the machine perfect.

6.Power distribution box use high quality gear which through high frequency quenching,make the machine durable.

7.Distribution gear use the hollow design,make no longer restricted the length of the screw,the length of screw is unlimited in

theory.

8.Use Time Relay,reduce the labour,make the screw thread have a high consistency.

TECHNICAL PARAMETERS

|

Model

|

3H30A/B

|

4H45A/B

|

4H55A/B

|

6H55A/B

|

6H70B

|

6H105B

|

6H40BL

|

8H80B

|

8H105B

|

|

Diameter Range

(mm)

|

2-3.5

|

2.5-4

|

3-5

|

4-6

|

4-6

|

4-8

|

4-8

|

5-8

|

5-10

|

|

Blank Length Max (mm)

|

30

|

45

|

55

|

50

|

70/85

|

105/125

|

40

|

80

|

105/125

|

|

Max Thread Length (mm)

|

30

|

40

|

50

|

45

|

70

|

100

|

40

|

75

|

100

|

|

Capacity

(pcs/min)

|

230-270

|

180-230

|

160-200

|

120-160

|

120-160

|

120-140

|

60

|

90-120

|

90-120

|

|

Main Motor(KW)

|

1.5

|

2.2

|

3

|

4

|

5.5

|

5.5

|

5.5

|

7.5

|

7.5

|

|

Height Of Die Pocket (mm)

|

25*30*70/80

|

25*45*76/90

|

25*55*85/100

|

25*50*110/125

|

25*70*110/125

|

25*105*110/125

|

40*40*235/260

|

30*80*150/170

|

30*105*150/170

|

|

Oil Motor

(KW)

|

0.18

|

0.18

|

0.18

|

0.18

|

0.18

|

0.18

|

0.18

|

0.37

|

0.37

|

|

Feed Motor(KW)

|

0.37

|

0.4

|

0.5

|

0.37

|

0.6

|

0.6

|

0.5

|

0.6

|

0.6

|

|

Packing Volume (cm)

|

150*91*140

|

170*125*150

|

172*130*150

|

185*125*150

|

195*145*160

|

200*160*160

|

234*140*160

|

245*150*160

|

244*170*160

|

|

NW (KG)

|

570

|

850

|

1170

|

1400

|

1500

|

1700

|

2500

|

3100

|

3200

|

|

Model

|

8H150B

|

10H105B

|

12H150B

|

12TH150B

|

14H105B

|

16H150B/C

|

20H150B/C

|

24H150C

|

|

Diameter Range

(mm)

|

5-10

|

6-10

|

8-14

|

8-14

|

8-14

|

10-18

|

16-22

|

20-25

|

|

Blank Length Max (mm)

|

150/200

|

105/125

|

150/200

|

150/200

|

105

|

150/250

|

150/250

|

150/250

|

|

Max Thread Length (mm)

|

150

|

100

|

150

|

150

|

100

|

150

|

150

|

150

|

|

Capacity

(pcs/min)

|

90-110

|

90-110

|

75

|

75

|

75

|

45-50

|

35-45

|

42

|

|

Main Motor(KW)

|

11

|

11

|

15

|

15

|

15

|

22

|

30

|

37

|

|

Height Of Die Pocket (mm)

|

30*150*150/170

|

30*105*150/170

|

40*150*190/210

|

40*150*190/210

|

40*150*190/210

|

40*150*235/260

|

50*150*285/310

|

50*150*380/420

|

|

Oil Motor

(KW)

|

0.37

|

0.37

|

0.37

|

0.37

|

0.37

|

0.36

|

0.36

|

0.36

|

|

Feed Motor

(KW)

|

0.8

|

0.8

|

0.8

|

0.8

|

0.8

|

1

|

2

|

4

|

|

Packing Volume (cm)

|

245*190*170

|

250*160*170

|

315*195*170

|

304*200*185

|

315*195*170

|

363*215*200+160*160*190

|

410*215*200+160*160*190

|

420*225*224+160*160*190

|

|

NW (KG)

|

3300

|

3500

|

4400

|

5200

|

4600

|

12300

|

14700

|

19000

|

FINISHED PRODUCTS

COMPANY INFORMATION

We reliably accompany you through everyday life. Mostly unnoticed.

After all, our precision-Fastener parts and Cold Forging

Technology are embedded into the products of our customers and, although not

always visible,they fulfil mission-critical functions there.

FAQ

1. who are we?

We are based in Hebei, China, start from 2018,sell to Domestic Market(53.00%),Eastern Europe(10.00%),Eastern Asia(6.00%),Mid East(6.00%),Southeast Asia(5.00%),Western Europe(5.00%),Africa(5.00%),South America(3.00%),Southern Europe(2.00%),Northern Europe(2.00%),North America(2.00%),Central America(1.00%). There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cold heading machine,cold forging machine,bolts nuts machine,screws machine,threading machine

4. why should you buy from us not from other suppliers?

Over 20 years of experiences in designing and manufacturing high level of metal forming machines

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,Spanish,Portuguese,French,Russian

We are based in Hebei, China, start from 2018,sell to Domestic Market(53.00%),Eastern Europe(10.00%),Eastern Asia(6.00%),Mid East(6.00%),Southeast Asia(5.00%),Western Europe(5.00%),Africa(5.00%),South America(3.00%),Southern Europe(2.00%),Northern Europe(2.00%),North America(2.00%),Central America(1.00%). There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cold heading machine,cold forging machine,bolts nuts machine,screws machine,threading machine

4. why should you buy from us not from other suppliers?

Over 20 years of experiences in designing and manufacturing high level of metal forming machines

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,Spanish,Portuguese,French,Russian

Hot Searches