- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

4800

-

Power:

-

32.5

Quick Details

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

veneer peeling lathe:

-

veneer peeling lathe

-

Weight:

-

4800

-

Power:

-

32.5

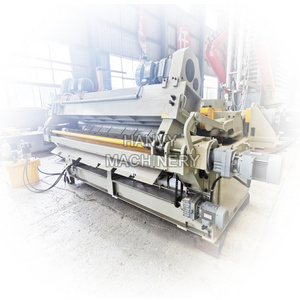

Veneer Peeling Lathe(All-in-One Veneer Peeling and Cutting)

Main Specifications

Model : SLXC1400

Max Processing Dia. : 300mm

Max Processing Length : 1350mm

Final Dia. : 28mm

Speed : 34.8mm

Veneer Thickness : 0.4-4.0mm

Weight : 4000kg

Power : 23.5kW

Main Charactor

1. Veneer peeling and cutting are all in one machine.

2.The edge is strickled manully, increasing flatness.

3.Steel plate structure for single-double-roller, channel steel

double-breasted welding for frame, stable and reliable.

4.High-performance digital systems, to produce even board

with high efficiency.

5.Adoption of automatic knife slit adjusting system, fit for big

diameter log.

6.Feeding system is equipped with nut and lead screw. The

nut is magnesium alloy material, durable.

7.rear axle uses decelerator feeding for low fault rate.

Production capacity

10-100 cubic meters (according the veneer thickness) a working

day(8 hours)

nude, wood case or as the clients' demands

Pre-sale

1. provide the free consultation of the machien

2.provide the standard device and the flow chart

3.according to the clients special requirement, offering the reasonable plan design to help to select the equipment

4.welcome to visit us

During sale

1.inspect the machine before leaving the factory

2.oversea install and debug the equipment

3.training the first-line operator

After sale service

1.24 hours online service

2.provide the video with install and debug the equipment

3.provide techincal exchanging