- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

200-300kg/h Sunflower Seed Sheller

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LFM Pumpkin Seeds Shelling Machine

-

Voltage:

-

380V, 50HZ, Three-phase Hemp Peeling Machine

-

Dimension(L*W*H):

-

6.2*2.5m*3.2m Pakistan Pine Nut Sheller

-

Weight:

-

1500 KG

-

Function:

-

Sunflower Seed Sheller

-

Capacity:

-

200-300kg/h

-

Usage:

-

Pakistan Pine Nut Sheller

-

Suit for:

-

Size Nuts

-

Color:

-

White

Quick Details

-

Marketing Type:

-

New Product

-

Type:

-

Automatic

-

Use:

-

Shelling Sunflower Seed Peeling Machine

-

Production Capacity:

-

200-300kg/h Sunflower Seed Sheller

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LFM Pumpkin Seeds Shelling Machine

-

Voltage:

-

380V, 50HZ, Three-phase Hemp Peeling Machine

-

Dimension(L*W*H):

-

6.2*2.5m*3.2m Pakistan Pine Nut Sheller

-

Weight:

-

1500 KG

-

Function:

-

Sunflower Seed Sheller

-

Capacity:

-

200-300kg/h

-

Usage:

-

Pakistan Pine Nut Sheller

-

Suit for:

-

Size Nuts

-

Color:

-

White

Products Description

Introduction Of

Watermelon Seed Cracker

The pine nut kernel shell separating machine

has reasonable designment,with low damage rate.The pine nut kernel shell separating machine is the most ideal hard nuts processing equipment currently.

Parameters

Pine Nut Shelling Sheller Processing Machine

Parameter

|

Name

|

Dimensions (m)

|

Weight (kg)

|

|

Upper hopper

|

1.1*1.1*1.15

|

50

|

|

Spiral elevator

|

0.9*0.9*1.6

|

120

|

|

Multifunctional cleaning machine

|

2.5*2.8*2.7

|

600

|

|

Grading screen

|

3.5*1.5*1.2

|

300

|

|

Receiving hopper

|

1.2*0.5*1

|

50

|

|

Bucket elevator

|

0.8*1.2*4.5

|

200

|

|

Disconnect host

|

3.2*2.8*3.3

|

2200

|

|

Check machine

|

2.8*1.5*1.6

|

900

|

|

Suction return material device

|

0.5*1.8*0.3

|

150

|

|

Receiving hopper

|

1.25*0.4*1.2

|

50

|

Important Reminder:

1.The technical parameters are for reference only.

2.The product quotation is for reference only, It is based on the actual purchased model and configuration.

3.For more information, please call or consult customer service.

Features Of

Pine Cone Cracker Machine

1. High peeling rate and whole kernel rate: after the

pine cone cracker machine

is peeled, the kernel content in the skin is <5%, and the whole kernel rate can reach more than 95%.

2. The material is clean after shelling: there is a cleaning device before the equipment is shelled, and the soil foam, large impurities, small impurities, and light impurities in the raw materials are processed by a multifunctional cleaning machine. Make the materials after shelling cleaner.

3. Convenient adjustment of the equipment: Each air duct of the equipment has an air volume adjustment device, which can easily adjust the appropriate air volume according to different conditions. At the same time, the angle of each screen body is adjustable, suitable for a variety of varieties.

4. High production efficiency and labor saving: The equipment adopts unit control, and the entire unit operation only needs two people to operate, which effectively saves labor.

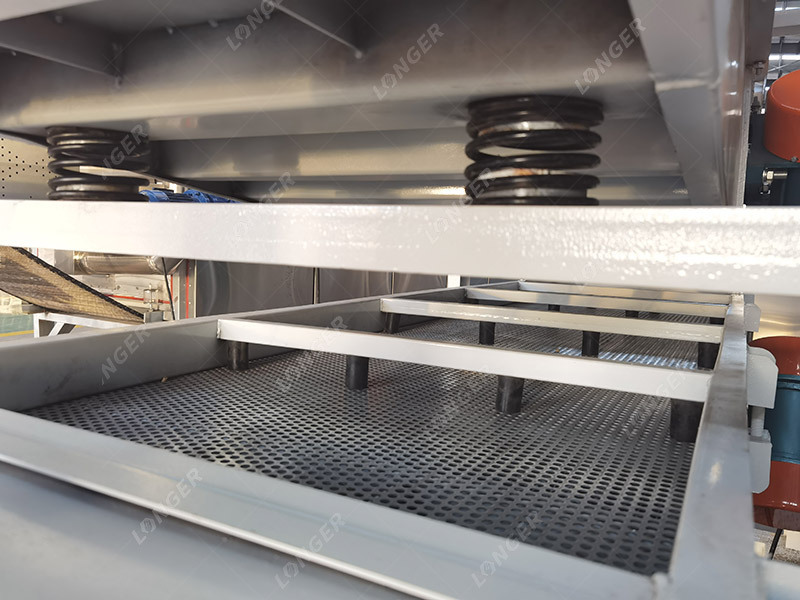

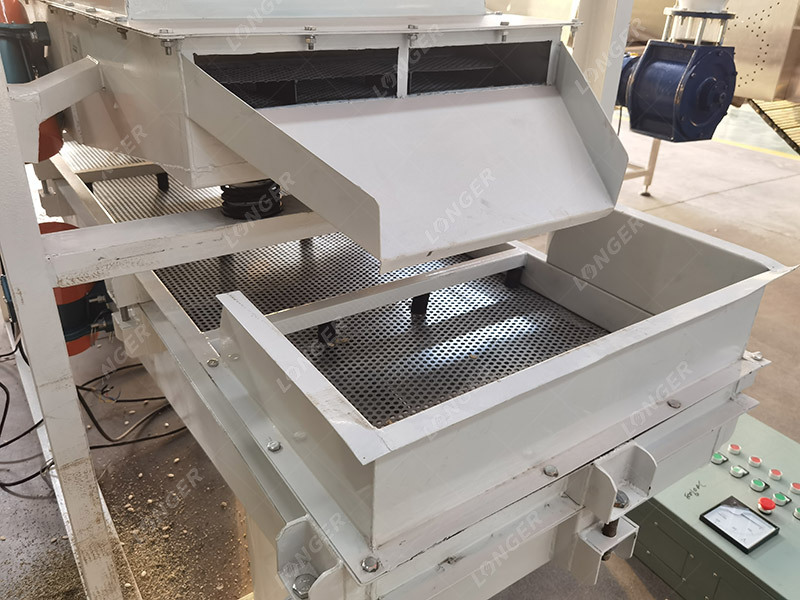

Detailed Images

FAQ

Q1

. What should be paid attention to for pumpkin seed shelling machine?

Soak the pumpkin seeds overnight, and then process them after drying. The shelling rate and the whole kernel rate are high.

Q2.

What is the water content of pine nuts suitable for processing?

The water content of pine nuts is about 12%-14%. The treatment effect is better. Fresh pine nuts need to be dried.

Q3.

What needs to be determined for buckwheat shelling?

Yield, size and type of buckwheat, sweet buckwheat or tartary buckwheat. Tartary buckwheat is generally too hard and needs to be steamed, then dried or sun-dried, so that the surface does not stick to your hands.

Q4.

What is the whole kernel rate of the buckwheat shelling machine?

The whole kernel rate is 90%, and the gap is adjusted to 100%.

Hot Searches