- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

60 KG

-

Marketing Type:

-

Hot Product 2023

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control system:

-

Semi-automatic and full automatic PLC

-

Cooling way:

-

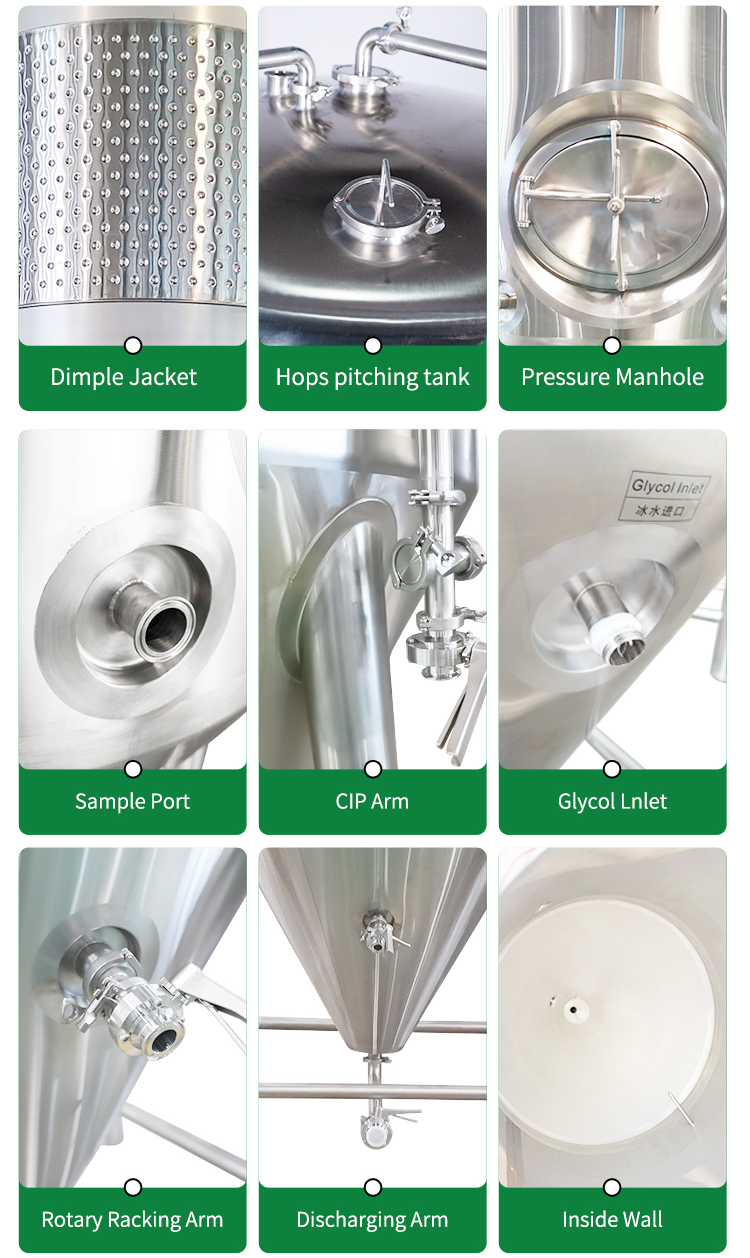

Dimple Jacket Plate

-

Capacity:

-

1BBL-160BBL

-

Material:

-

SUS304/SUS316/red Copper

-

Welding:

-

100% TIG Welding

-

Polishing:

-

0.2-0.4um/Mirror Polished

-

SUS thickness:

-

inner wall 2mm surface 3mm

-

Application:

-

fermentation

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Tiantai

-

Voltage:

-

220-415V

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

60 KG

-

Marketing Type:

-

Hot Product 2023

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Control system:

-

Semi-automatic and full automatic PLC

-

Cooling way:

-

Dimple Jacket Plate

-

Capacity:

-

1BBL-160BBL

-

Material:

-

SUS304/SUS316/red Copper

-

Welding:

-

100% TIG Welding

-

Polishing:

-

0.2-0.4um/Mirror Polished

-

SUS thickness:

-

inner wall 2mm surface 3mm

-

Application:

-

fermentation

-

Certification:

-

CE ISO

PRODUCTS DESCRIPTION

PRODUCTS ADVANTAGES

1. The fermentation tank is equipped with lifting ears, which is convenient for hoisting equipment in place.

2. With a rotating elbow and racking tam for beer delivery, it is convenient and flexible to deliver beer.

3. An elliptical guard plate is added at the junction of the outriggers and the lower cone refrigerant inlet pipe and the lower cone outsourcing to ensure more precise machining accuracy.

4. All tanks are equipped with adjusting bolts to ensure the tanks are aligned and leveled.

5. The clamp is installed at the connection between the material port and the bottom of the tank, which can be rotated at will, which is convenient for customers to operate.

6. Outsourcing of the bottom of the Bright tank is made of finished products to ensure that the tank body has a beautiful appearance, strong and durable.

7. All bright tanks are equipped with carbon stones for CO2.

8. Uses a shadowless manway, which is easy to clean. The top manhole can be designed according to the customer’s fermentation process and brewing beer.

9. The headspace is large, the total volume does not include the volume of the top head.

10. The cooling jackets are designed on both top of the cone and the bottom of the cylinder, and the cooling area is large enough.

11. Equipped with safety device, positive and negative pressure opening function.

12. The 60-degree cone angle is convenient for yeast excretion.

13. The fermentation tank is equipped with a special ladder for easy operation.

14. The working platform adopts water leakage and a non-slip design.

15. Brewhouse manways always use full glass manway.

Product Parameters

|

Effective volume

|

200L

|

500L

|

1000L

|

1500L

|

2000L

|

2500L

|

3000L

|

4000L

|

5000L

|

||||||||

|

Total volume

|

250L

|

625L

|

1250L

|

1875L

|

2500L

|

3125L

|

3750L

|

5000L

|

6250L

|

||||||||

|

Size

|

850*

1600mm

|

960*

2050mm

|

1160*2500mm

|

1260*2800mm

|

1460*

3050

mm

|

1700*

3350

mm

|

1750*

3450

mm

|

1800*

3550

mm

|

1900*

4250

mm

|

||||||||

|

Material

|

SUS304/SUS316

|

|

|

|

|

|

|

|

|

||||||||

|

Control system

|

PLC Siemens or PID Schneider/ABB brand

|

|

|

|

|

|

|

|

|

||||||||

|

Cooling area

|

0.8㎡

|

1.3㎡

|

2.6㎡

|

3㎡

|

4㎡

|

4.4㎡

|

4.7㎡

|

6.3㎡

|

8.0㎡

|

||||||||

|

Work pressure

|

inner jacket 0.4MPa; cooling jacket 0.5Mpa

|

|

|

|

|

|

|

|

|

||||||||

|

Design pressure

|

inner jacket 0.2MPa; cooling jacket 0.3Mpa

|

|

|

|

|

|

|

|

|

||||||||

Control System

we offer several levels of automation for the brewing systems (Advancedcontrols, basic controls, custom controls).

Such as advanced system that is a PLC / touchscreen based system anda more basic system with individual controls.

Assistance System

Tiantai provides other auxiliary equipment, please contact us if necessary

Product Advantages

1. We can customize the equipment design as per customer brewing method and brewing beer types .

2. All Construction uses high-quality SUS 304 food-grade stainless steel, all pipes are SUS304, perfect 3mm inner

2. All Construction uses high-quality SUS 304 food-grade stainless steel, all pipes are SUS304, perfect 3mm inner

shell and 2mm outer shell.

3. All tanks are equipped with specially designed jackets to ensure heating and cooling efficiency. Both cone top and

3. All tanks are equipped with specially designed jackets to ensure heating and cooling efficiency. Both cone top and

shell bottom have jackets, exchanging areas are big enough.

4. The headspace of our tanks is much bigger, the total volume does not include the cover headspace.

5. 100% TIG welding process to weld the tank, jackets welding are all full welding by water, uniform dimpled cooling

4. The headspace of our tanks is much bigger, the total volume does not include the cover headspace.

5. 100% TIG welding process to weld the tank, jackets welding are all full welding by water, uniform dimpled cooling

jacket to ensure no leaking and long life, welds passivated!

6. Our polishing is overall mirror polishing, polishing 6 times to make Ra 0.4um mirror finish, can clean 360° without

6. Our polishing is overall mirror polishing, polishing 6 times to make Ra 0.4um mirror finish, can clean 360° without

dead ends.

7. Jacket testing 12 hours with air and water, jacket testing pressure is 5Bar, internal shell testing pressure is 4Bar, and

before packing we will also have 48hours of water testing.

8. Strict quality control and process inspection & testing system, which all the testing records will show on our data

7. Jacket testing 12 hours with air and water, jacket testing pressure is 5Bar, internal shell testing pressure is 4Bar, and

before packing we will also have 48hours of water testing.

8. Strict quality control and process inspection & testing system, which all the testing records will show on our data

late with the tanks shipping, with checking the list and serial numbers to track.

9. We insist on a high-end product line to manufacture our tanks, all components like chiller, exchanger, steam boiler, and

Schneider/ABB electronics control systems all adopt international brands to ensure quality and convenient after-sales.

9. We insist on a high-end product line to manufacture our tanks, all components like chiller, exchanger, steam boiler, and

Schneider/ABB electronics control systems all adopt international brands to ensure quality and convenient after-sales.

OUR SERVICE

Pre-sales service

-Layout:Sent us your building floor plan, or the sketch, or tell us the size (length, width, height), we will offer you an

equipment footprint according to your requirement.

equipment footprint according to your requirement.

-Technical Drawings : We will offer Technical Drawings of each tank based on the equipment layout .

-3D effective sketch: We will 3D effective sketch to make sure ensure you have a more intuitive experience.

After service

We guarantee the quality of the electrical elements within one year and tanks body within 1 years. If the electrical elements go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After warranty, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support. We can also dispatch our engineer to your brewery to install and adjust the machines for you. He can also train your staff to use the equipment.

OUR USERS&EXHIBITION

WHY CHOOSE US

Quallty Inspection&Certificates

Certification Authority EUROPE USA AUSTRALIA RUSSIACertificated by Is09001/CE/UL/EAC/ECM

Technology Patent Certificate

CUSTOMER FEEDBACK

FAQ

1.Q:Does your company have foreign installation experience?

A: Yes, our company has installation experience in USA, Canada, Europe, Australia, Malaysia, Myanmar, South Africa etc.

2.Q: Do you have a professional engineer or after-sales team in our country?

A: Yes, our equipment is sold to 103 countries and areas and we have our local after-sales service personnel in Europe, America and Asia.

3.Q:How can you guarantee the delivery date of the equipment after we place the order?

A: The delivery time can be ensured through Alibaba Credit Insurance orders.

4.Q:What payment methods are supported?

A:T/T, L/C, Credit Card, VISA, Apple device, Western Union.

5. Q: How long the warranty will be?

A: 5-year warranty, only for tanks, excluding electrical appliances, wearing parts such as cushions, seals, etc. (mixing seals, pump seals, butterfly valves and other valve seals), pumps.

6. Q:How about the installation and training?

A:We can supply the installation and training. There are two options. The first option: We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. The second option: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford the transportation cost.

7.Q: Can I be your company's sales agent?

A: Yes, it’s our pleasure. We very much welcome you to join us. Please contact us to discuss specific details.

8.The price does not include electrical appliances, etc.

Send Inquiry

Please click to contact us for more information!

Hot Searches