- Product Details

- {{item.text}}

Quick Details

-

Function:

-

Acid-Resistant, Firebrick

-

Surface Treatment:

-

Matte

-

Place of Origin:

-

Henan, China

-

Model Number:

-

DN-69003

-

Water Absorption:

-

6%

-

Name:

-

white stone veneer

-

Surface:

-

matt

-

Thickness:

-

4mm

-

Craft:

-

Temperature controlled molding

-

Advantages:

-

safe,lightweight,fireproof

Quick Details

-

Project Solution Capability:

-

graphic design

-

Application:

-

Exterior

-

Design Style:

-

Modern

-

Function:

-

Acid-Resistant, Firebrick

-

Surface Treatment:

-

Matte

-

Place of Origin:

-

Henan, China

-

Model Number:

-

DN-69003

-

Water Absorption:

-

6%

-

Name:

-

white stone veneer

-

Surface:

-

matt

-

Thickness:

-

4mm

-

Craft:

-

Temperature controlled molding

-

Advantages:

-

safe,lightweight,fireproof

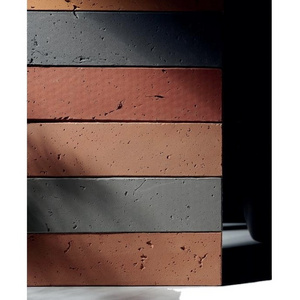

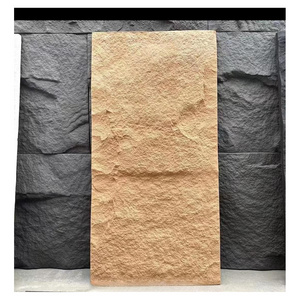

White stone veneer waterproof flexible facing brick exterior wall panel

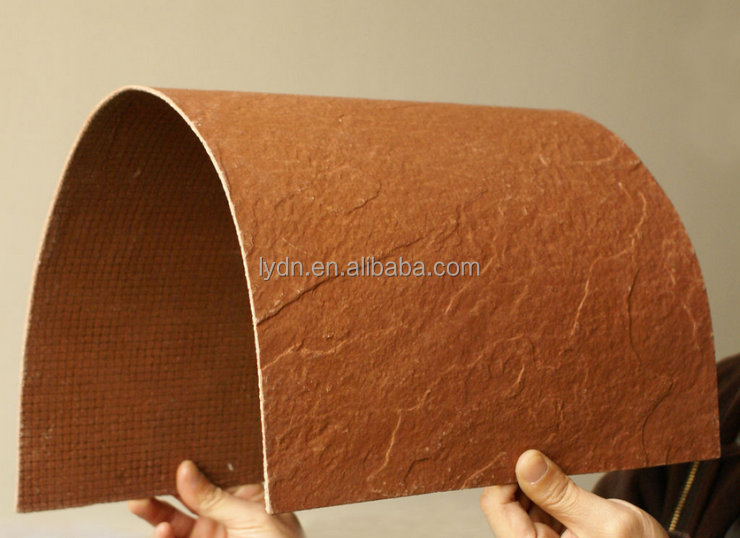

The flexible tiles are the tiles with elastic and pliable properties baked from ordinary soil.

The tiles can instead of traditional wall tiles and stone.Soft porcelain technology is a deduction equation that adds "flexible" elements to ceramics, baking ordinary

soil into ceramic tiles with elastic and flexible properties, completely changing the hard, cold, heavy and fragile texture of ceramics.

soil into ceramic tiles with elastic and flexible properties, completely changing the hard, cold, heavy and fragile texture of ceramics.

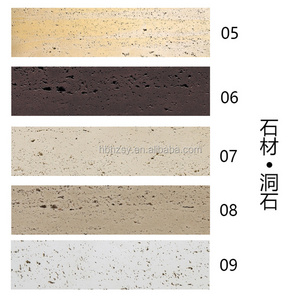

Specification

|

Name

|

white stone veneer

|

|

Material

|

MCM

|

|

Surface

|

matt

|

|

Size

|

300*600*4mm, 600*1200*4mm

|

|

Style

|

classic,rustic

|

|

Water absorption

|

6%

|

|

Craft

|

Temperature controlled molding

|

|

Advantages

|

lightweight,safe,environmental,fireproof

|

|

Usage

|

exterior and interior wall decoration

|

Product Description

Brick veneers

Wood grain

Clay board for interior

Application Projects

The

light flexible tiles

can be used for many buildings like the Vi

lla ,School ,Hospital , Hotel, R

esidential building, Plaza and so on.Bright you the different feeling.

Installation

Step 1

After the base layer is treated with a special interface agent, bounce the horizontal and vertical positioning lines

Step 2

Use a small spatula to spread the prepared adhesive on the back of the soft porcelain, and the filling rate should be more than

80%.

80%.

Step 3

Paste the outer corner first and then the large surface, adjust the width of the seam by adjusting the pressure, and tap with a

rubber plate to make it evenly bonded

rubber plate to make it evenly bonded

Step 4

Put the caulk into a triangular plastic bag, cut out a small opening in the plastic bag and then fill in the seam

Step 5

After the caulk is half dry, pull out the concave seam with the bent steel head. The steel head should be wider than the seam

Step 6

Remove the spilled caulk with a brush and wipe the soft porcelain clean with a semi-wet sponge

Hot Searches