- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

aluminium mould die

-

Product Name:

-

aluminum injection mold make precision injection injection production

-

Certification:

-

CE RoHS ISO9001

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

Surface treatment:

-

Polish. Etched. Texture

-

Mould material:

-

P20/718/2738/H13/S136/NAK80

-

Drawing Format:

-

Dwg .step .igs.x-t .solidwork

-

MOQ:

-

1 Set

-

Color:

-

Customized Colors

-

Cavity:

-

Single

-

Mould life:

-

100000-1000000shots

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

A-R mould

-

Model Number:

-

aluminium mould die

-

Product Name:

-

aluminum injection mold make precision injection injection production

-

Certification:

-

CE RoHS ISO9001

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

Surface treatment:

-

Polish. Etched. Texture

-

Mould material:

-

P20/718/2738/H13/S136/NAK80

-

Drawing Format:

-

Dwg .step .igs.x-t .solidwork

-

MOQ:

-

1 Set

-

Color:

-

Customized Colors

-

Cavity:

-

Single

-

Mould life:

-

100000-1000000shots

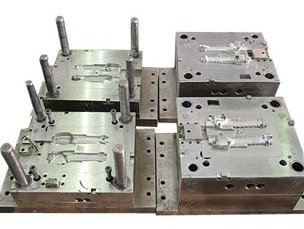

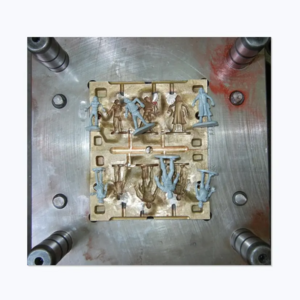

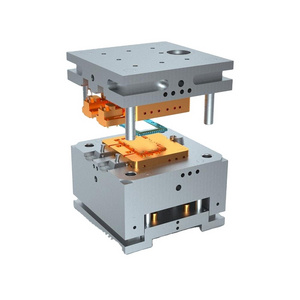

aluminum injection mold make precision injection injection production of china plastic mould die manufacturer

| Production Technology | Plastic injection molding production |

| Mold Material | S50C, P20, 718H, NAK80, S136, S136H, H13 |

| Mold Life Time | 300K shots |

| Product Material | ABS, PC, PP, PE, HIPS, PVC, PS, POM, Acrylic, PMMA, PC+ABS |

| Surface Treatment | Smooth, glossy, textured, matte |

| Size | 1) According to customers' drawings |

| 2) According to customers' samples | |

| Drawing Format | step, dwg, igs, pdf |

| Payment Term | T/T, L/C, Trade Assurance |

| Delivery Time | 3-5 weeks after order confirmed |

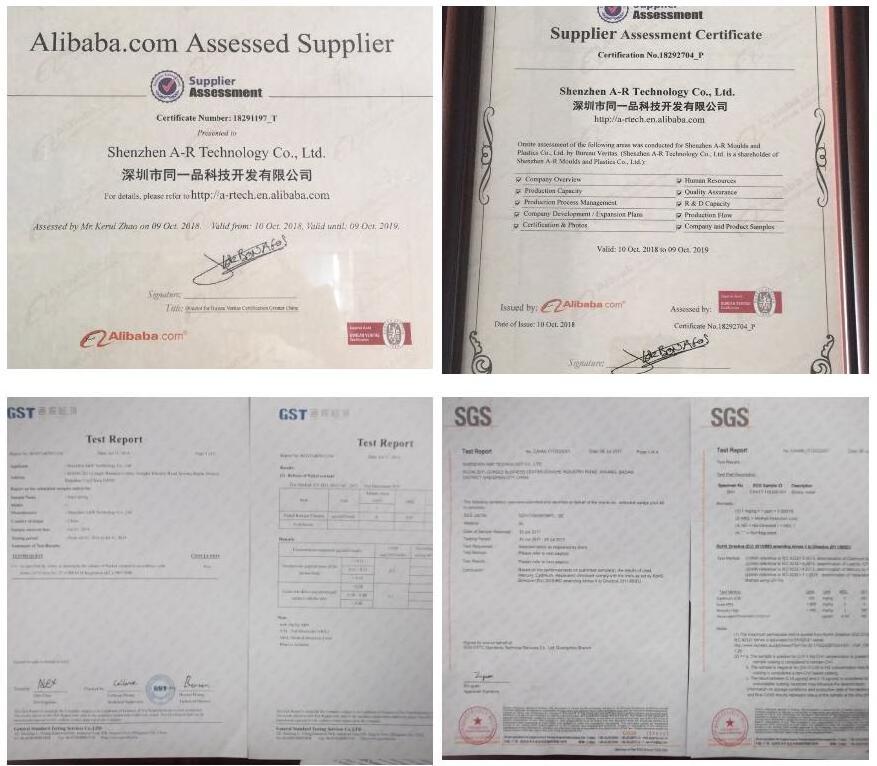

Established in 2002,

Shenzhen A&R Technology Co., Ltd

mainly specializes in the design,molding, plastic injection parts and assembling covering a variety fields.

We have facilities of

plastic mould & injection, silkprint, Assembly

. So we are capable of supply the package service from the design to manufacturing of various electronic products and home appliances.

Product Range:

Electronic: sensor, USB housing, etc

Mobile phone plastic part, remote control, key-press, fingerprint head, handle, cover

Mechanical: Junction box, Motor support part, Pump plastic part

Household: Industrial number calculator part, Juice cup, safety helmet

Medical: hearing aids, Hollow fiber Dialyzer, Blood-Pressure meter, Stapler

Sport: Golf plastic part

Office: Secret code case part, Printer, duplicator, Atom seal

We offer the whole solution of service as following:

1, Part design assistance (with our suggestions you can save the mold cost)

2, Prototype

3, Mold design

4, Mold manufacturing

5, Mold test

6, Mold modification

7, Plastic part injection molding

8, Painting, silk screen, assembly

9, Packaging and delivery

Our Advantage:

-16years manufactoring&exporting experience

-One stop serevice for plastic parts, moulds and assemblying.

-we have 5experienced engineer, 3 administrative people, 5 QC.

-With the objective of responsible and professional service, quality products, fine price, on time delivery.

-can accept small order with good service,customer can find us at any time,we can give design or production suggestion

Our Service:

Product Show:

Q:How can you confirm the plastic injection mold you produce is the one we need?

A: we can provide professional mold analysis reports before mold making .

Q:What can we do if we do n’ t have the mold drawing ?

A: you will only provide the actual sample to us then we can help you to make the design injection mold drawings for your confirmation

Q:Can we test the plastic injection mold?

A: after the mold is ok ,we can help you to test the mold for free.

Q:Can you process the die-casting parts of injection mold?

A: We can help to proce ss d ie-casting parts for small run or mass production.

Q:What about the plastic products samples are wrong?

A: if you are not satisfied with the plastic sample, we can send the sample to you again for free.