- Product Details

- {{item.text}}

Quick Details

-

Screw Design:

-

single stage /double stage/ third stage

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

according customized

-

Power (kW):

-

30kw or customized

-

Weight:

-

8

-

Material:

-

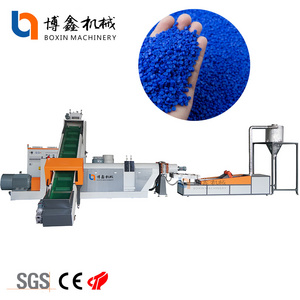

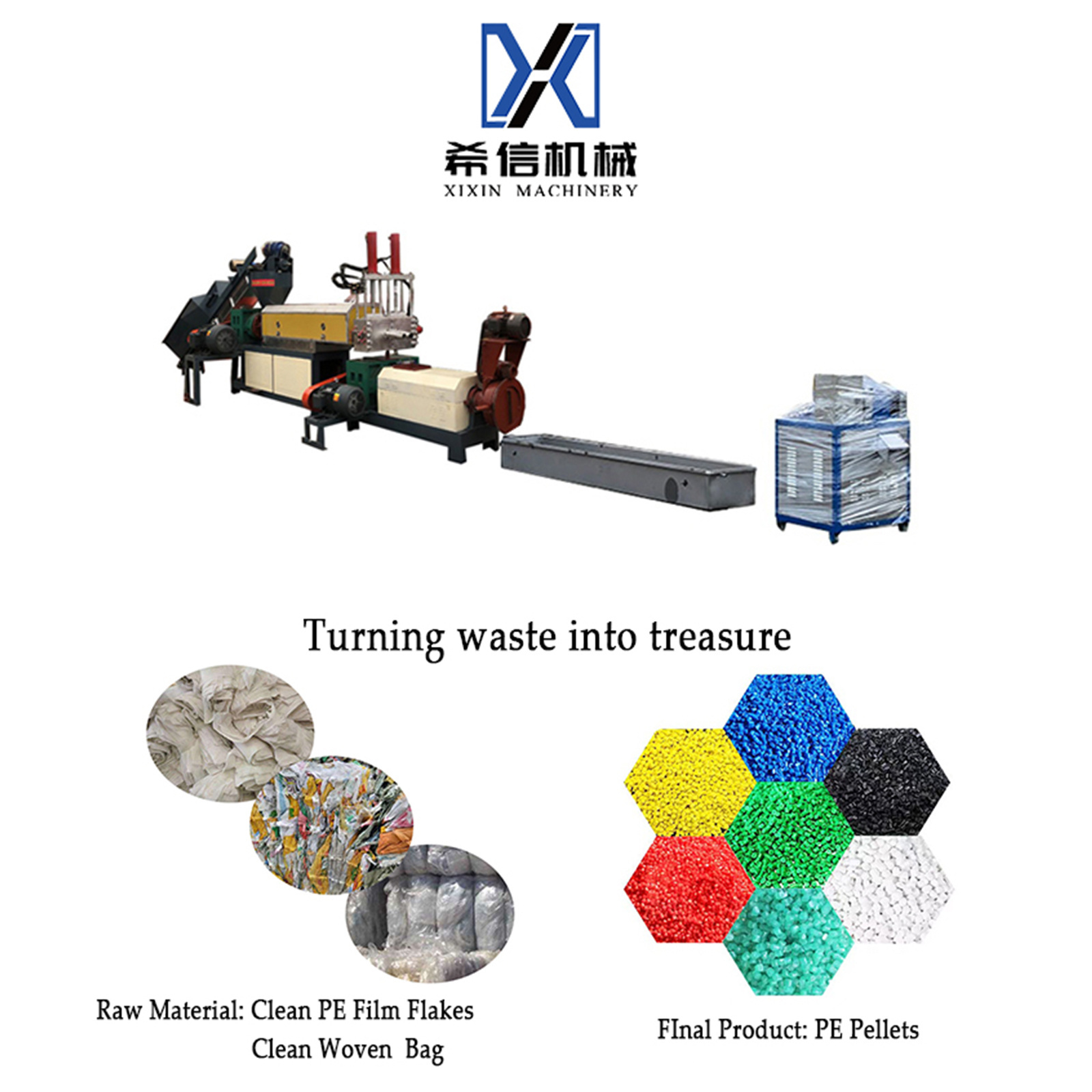

PP/PE/HDPE/LDPE

-

Color:

-

Customized Color

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Output (kg/h):

-

100 - 500 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

X|IXIN

-

Screw Design:

-

single stage /double stage/ third stage

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

according customized

-

Power (kW):

-

30kw or customized

-

Weight:

-

8

-

Material:

-

PP/PE/HDPE/LDPE

-

Color:

-

Customized Color

-

Marketing Type:

-

Ordinary Product

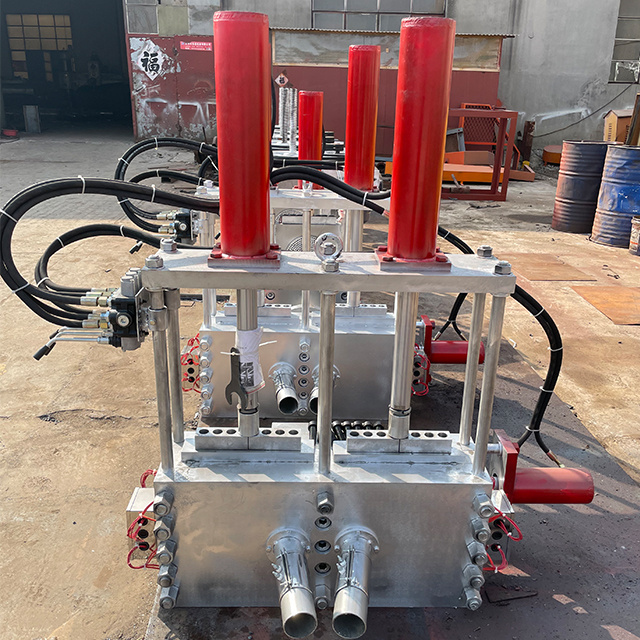

different quality granules. There is also other screen changer for your option.

Production Process

Features:

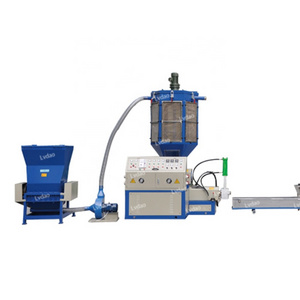

*with advanced low-noise hard surface gear box, assuring the main granulator fit for continuing high speed running.

*With air drier, vibrating screen screen and storage hopper, making the grains classifying and cooling, the pelletizing process automatically and operation convenient.*High quality electrical and driving equipment make the machine equipment more safe and reliable in use.

The feeding machine is a forced feeder, which has the characteristics of uniform feeding, good continuous performance, simple operation and labor saving.

without inclusion). The plastic granulator is used for various plastic granulation.The screw is designed according to the material characteristics, with high output, good luster of the material, full particles, increased configuration of the whole machine,increased service life of the equipment.

granulation.

granulation without artificial feeding, automatic feed and cut, every single breaking score, low noise, light and convenient,

suitable for use in all kinds of granulating machine matching.

Pre-Sales Service

* Inquiry reply within 24 hours.

* Products consultation.

* Quotation.

After-Sales Service

* Commissioning and technical training.

* Engineers available to serve overseas.

* Repair service and online support.

1. Are you a trading company or manufacturer?

We are a manufacturer. We have own factory and we have specializing in manufacturing plastic machinery for 30 years.

2. How about the output about this machine?

The output differs machine to machine. We have tested our machine for many times, the machine we sold can meet your demand.

3.How about the quality of your machine?

Our machine is in good quality and our products are unanimously recognized by domestic and foreign customers.

4. Where is your factory?

Our factory is located at Luwang industrial park,Laizhou city, Yantai city, Shandong province, China.