- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hospital

-

Design Style:

-

Modern

-

Type:

-

calcium silicate board

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SANLE

-

Model Number:

-

calcium silicate board

-

Feature:

-

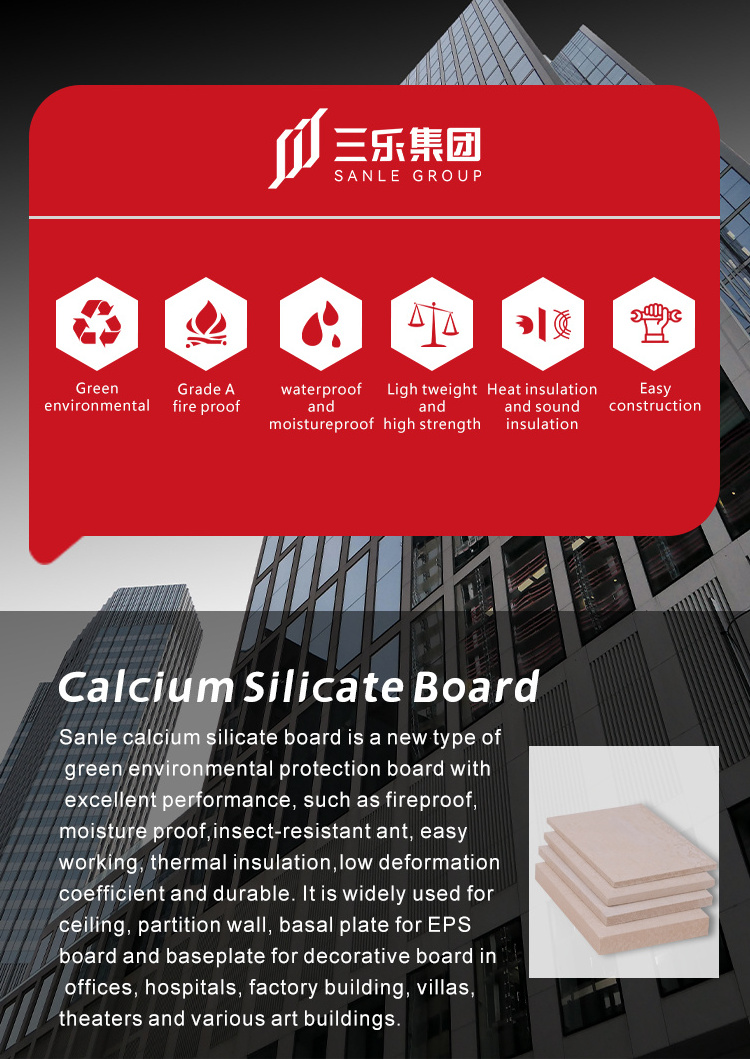

Environment friendly,light weight,high strength,fireproof, waterproof

-

Product Name:

-

calcium silicate board

-

Density:

-

1.2-1.6g/cm3

-

Certification:

-

ISO, CE

-

thermal conductivity:

-

0.29 W/(m.k)

-

Usage:

-

ceiling, wall partition, EPS panel

-

Edge:

-

Square Edge

-

water absorption:

-

38%

-

non-combustibility:

-

class A

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Training, Onsite Inspection

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Hospital

-

Design Style:

-

Modern

-

Type:

-

calcium silicate board

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SANLE

-

Model Number:

-

calcium silicate board

-

Feature:

-

Environment friendly,light weight,high strength,fireproof, waterproof

-

Product Name:

-

calcium silicate board

-

Density:

-

1.2-1.6g/cm3

-

Certification:

-

ISO, CE

-

thermal conductivity:

-

0.29 W/(m.k)

-

Usage:

-

ceiling, wall partition, EPS panel

-

Edge:

-

Square Edge

-

water absorption:

-

38%

-

non-combustibility:

-

class A

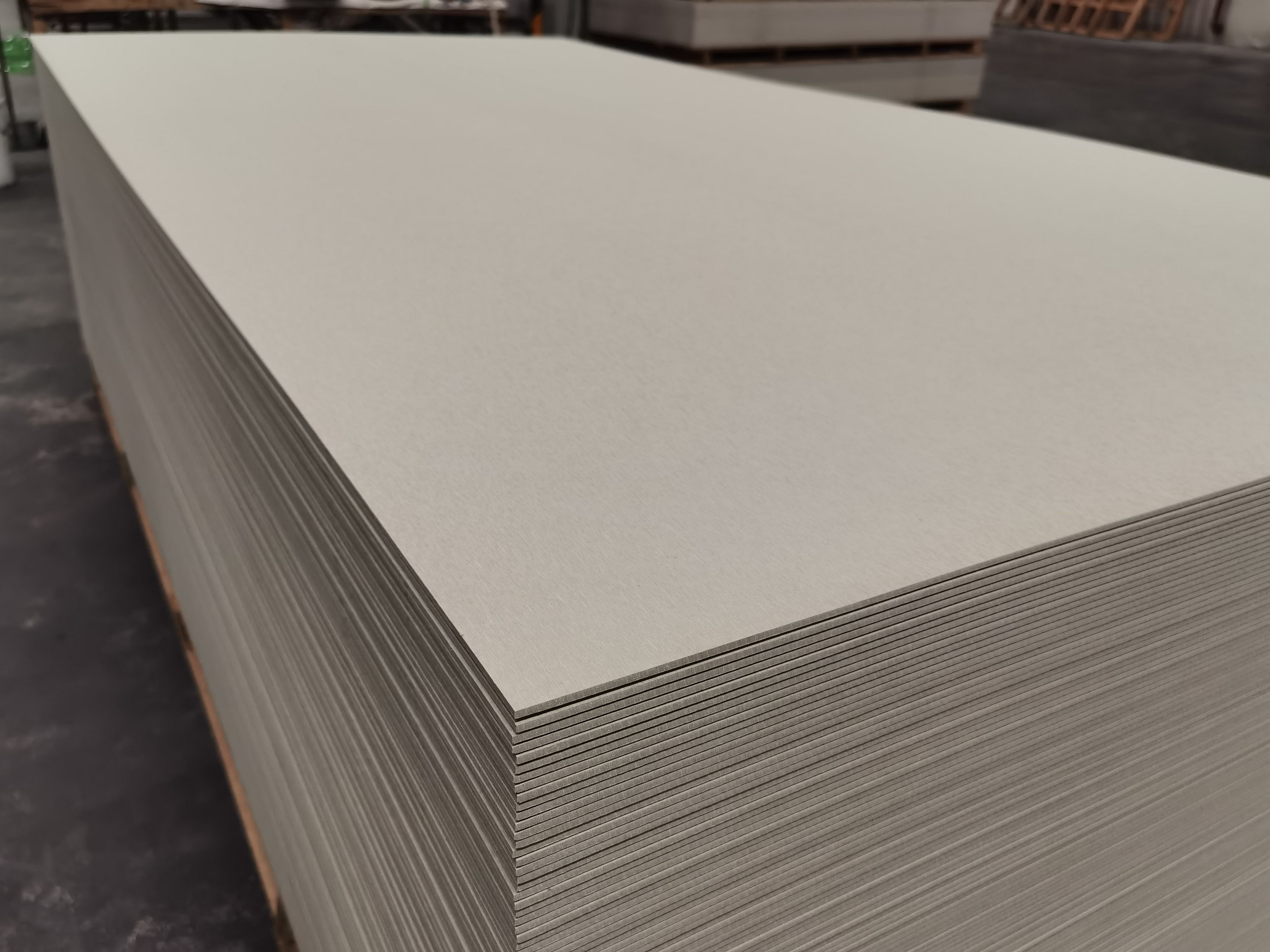

| Specification: | ||

| Thickness(mm) | Width(mm) | Length(mm) |

| 4-30 | 1220 | 2440 |

| Dimensional deviation: | ||

| Thickness | ≤8mm | ±0.3mm |

| ≥ 9mm | ±0.5mm | |

| Width | ≤1220mm | ±3mm |

| >1220mm | ±4mm | |

| Length | ≤2400mm | ±4mm |

| >2440mm | ±5mm | |

| Physical properties: | ||

| Density | 1.2-1.6g/cm3 | |

| Thermal conductivity | ≤0.29 W/(m.k) | |

| Water absorption | ≤40% | |

| Water contain | ≤10% | |

| Moisture movement | ≤0.25% | |

| Bending strength | average | >12 Mpa |

| strength ratio | >60% | |

| Non-combustibility | class A | |

1. The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

2. The vertical keel should be aligned well according to the requirement (generally being 612 mm) with laterally supporting keel installed.

3. Cutting the board material to the dimensions needed (about 10mm lower than wall height)

4. Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250mm with screws sinking 0.5mm under the board face.

5. The expansion seam of about 4mm between boards should be kept.

6. The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking.

7. Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

1.Carry out ceiling line-measuring to determine the ceiling’s fixed position, the boom’s central range is generally 1200.

2.Connect and fix the boom and main keel with hanging piece to make the main keel keep level position.

3.Vertically fix the sub-keel to the main keel with hanging piece; the sub-keel axis’central range is 612mm.

4.Install the laterally supporting keel properly, its central ranges is 1224mm.

5.Fix the board on sub-keels with tapping screws, and to well the seam-connecting treatment.