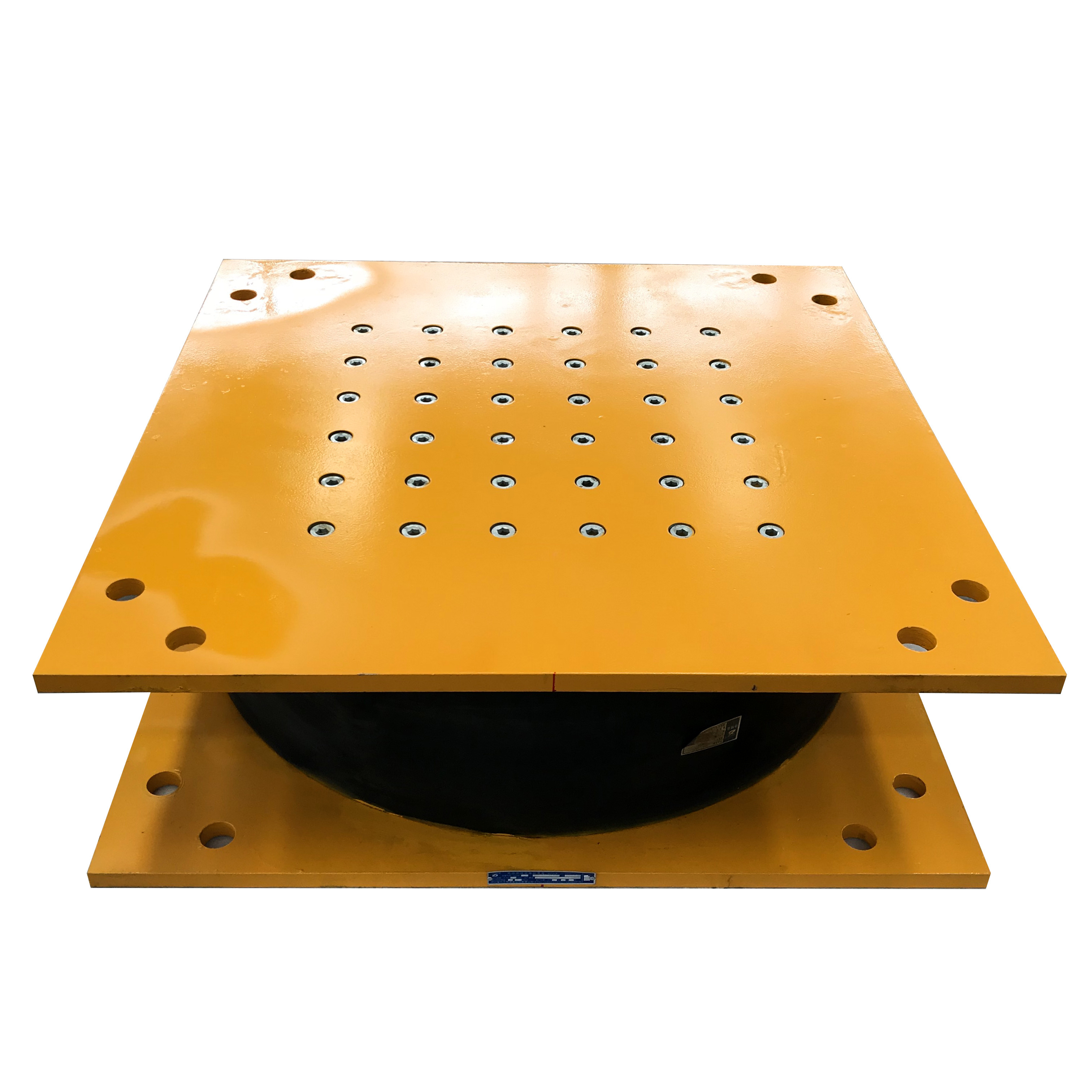

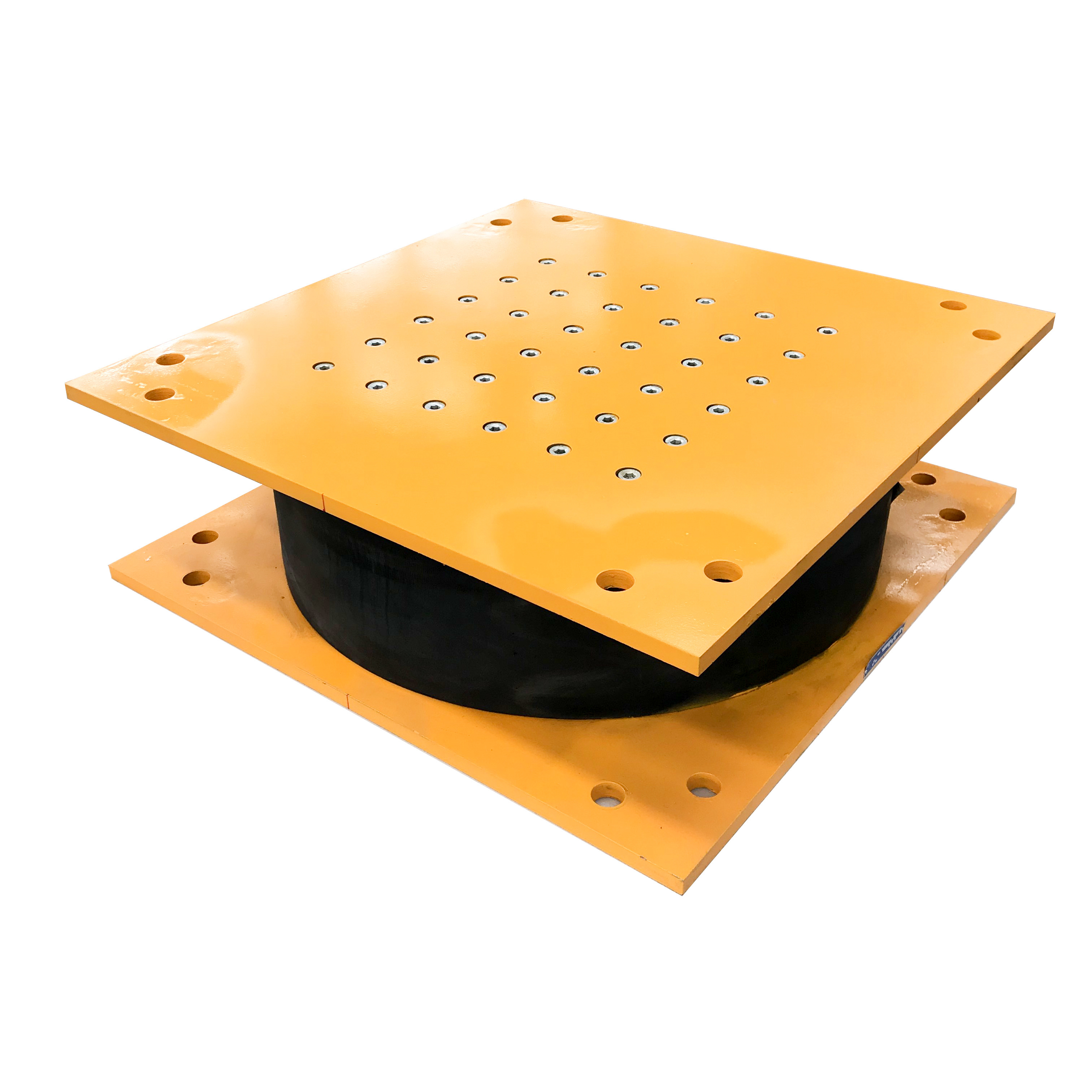

2-top steel plate

3-top connection plate

4-screw

5-elastomer

6-reinforced steel plate

7-sleeve; 8-anchor bolt

9-rubber cover

10-bottom connection plate

11-bottom steel plate

12-bottom anchor plate