Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Gonzem

-

Model Number:

-

H-1

-

Surface treatment:

-

Black

-

Size:

-

M3~M52

-

Product name:

-

Hex Head Bolt

-

Grade:

-

8.8/10.9/12.9

-

Delivery time:

-

Normally in 30-40 days

-

Package:

-

Cartons&pallets or according to customer''s requirement.

Quick Details

-

Finish:

-

ZINC, Plain

-

Material:

-

Stainless steel, Steel

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gonzem

-

Model Number:

-

H-1

-

Surface treatment:

-

Black

-

Size:

-

M3~M52

-

Product name:

-

Hex Head Bolt

-

Grade:

-

8.8/10.9/12.9

-

Delivery time:

-

Normally in 30-40 days

-

Package:

-

Cartons&pallets or according to customer''s requirement.

Specification

|

Standard

|

DIN912

|

|

Grade

|

8.8/10.9/12.9

|

|

Material

|

Medium carbon steel and alloy steel

|

|

Finish

|

Black

|

|

Size

|

M3-M52

|

|

Mark

|

According to customer's requirement

|

|

Quality

|

Top high quality

|

|

Package

|

Cartons & pallets or according to customer's requirement

|

Product Description

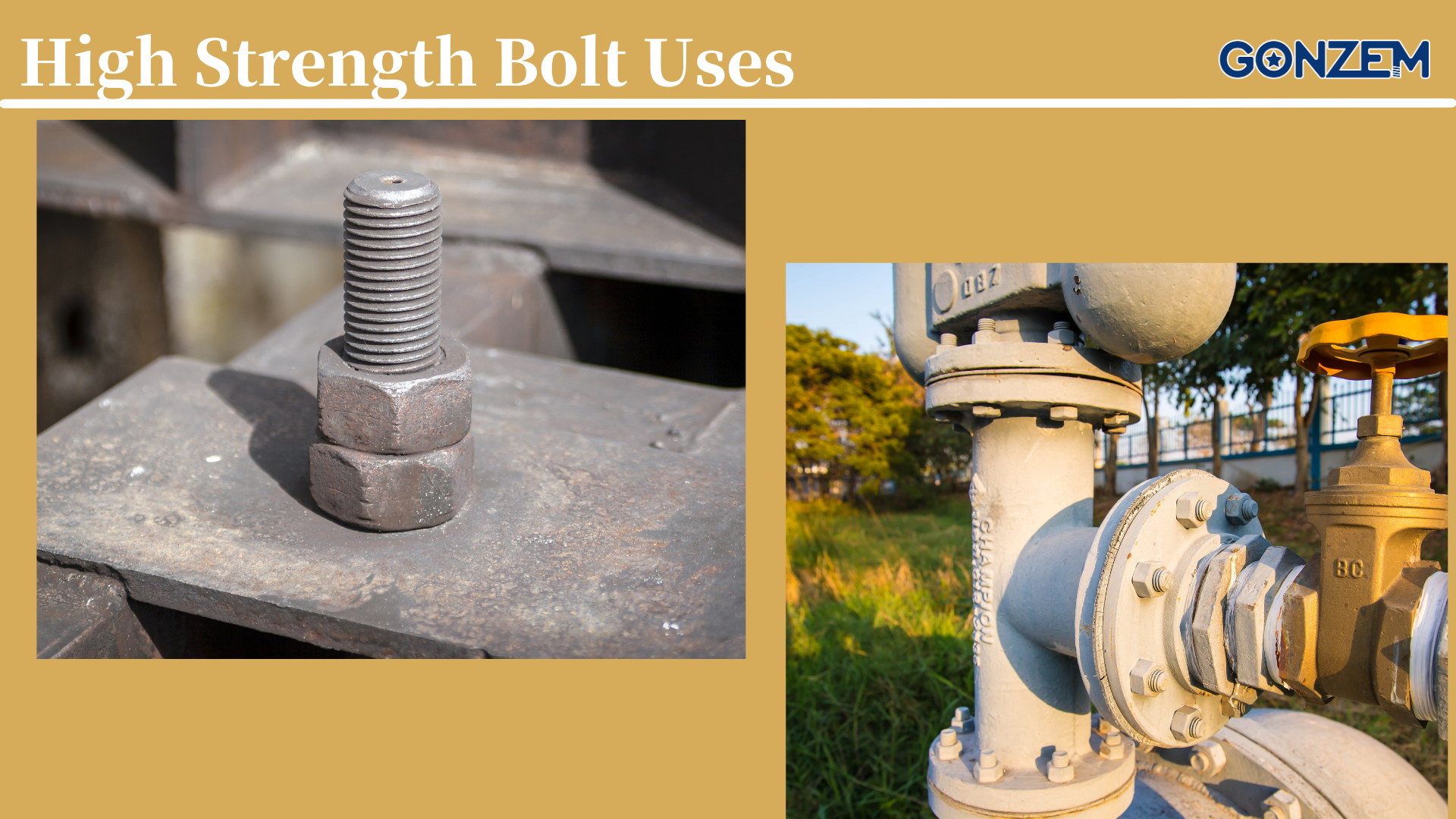

High tensile bolts made of high-strength steel, or bolts that require greater pre-tightening force, can be called high-strength bolts.

High-strength bolts are mostly used for the connection of bridges, rails, high-pressure and ultra-high pressure equipment. Thefracture of this kind of bolt is mostly brittle fracture. High-strength bolts applied to ultra-high pressure equipment need to be prestressed in order to ensure the sealing of the container. Several concepts about high-strength bolts 1. According to the requirements of the performance level of bolts above 8.8, it is called high-strength bolts .

High-strength bolts are mostly used for the connection of bridges, rails, high-pressure and ultra-high pressure equipment. Thefracture of this kind of bolt is mostly brittle fracture. High-strength bolts applied to ultra-high pressure equipment need to be prestressed in order to ensure the sealing of the container. Several concepts about high-strength bolts 1. According to the requirements of the performance level of bolts above 8.8, it is called high-strength bolts .

The difference between the two is the difference in material strength.

From the perspective of High tensile bolts raw materials:

High strength bolts are made of high-strength materials. The screws, nuts and washers of high-strength bolts are all made of high-strength steel, commonly used 45 steel, 40 boron steel, 20 manganese titanium boron steel, 35CrMoA, etc. Ordinary bolts are usually made of Q235 (equivalent to A3 in the past) steel.

From the perspective of High tensile bolts raw materials:

High strength bolts are made of high-strength materials. The screws, nuts and washers of high-strength bolts are all made of high-strength steel, commonly used 45 steel, 40 boron steel, 20 manganese titanium boron steel, 35CrMoA, etc. Ordinary bolts are usually made of Q235 (equivalent to A3 in the past) steel.

High-strength bolts have a variety of uses due to their increased tensile strength. The most common benefits include heavy machinery, significant structures, bridges, ships, railroad tracks, and cars. The increased tensile strength allows these items to be connected securely without fear of failure under extreme pressure or vibration.

High-strength bolting also ensures that the components remain secure even in harsh weather conditions or when exposed to corrosive materials. They have been treated with special coatings or platings that protect them from rusting or corrosion over time.

High-strength bolting also ensures that the components remain secure even in harsh weather conditions or when exposed to corrosive materials. They have been treated with special coatings or platings that protect them from rusting or corrosion over time.

Hot Searches