Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS Mach

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

30*10*5

-

Power (kW):

-

150

-

Weight:

-

15000

-

Product:

-

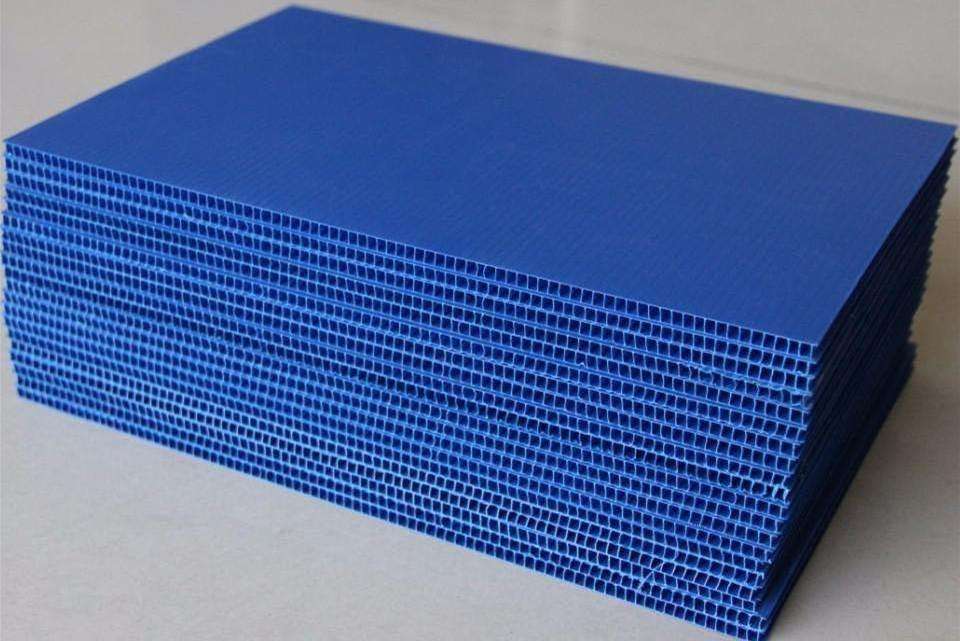

pp hollow sheet

-

L/D:

-

32-62

-

Raw material:

-

PP Granules/ Flakes

-

Usage:

-

Plastic Extrusion

-

Processing Type:

-

Exturding Machine

-

Automatic Grade:

-

Automatic Controll

-

Inverter:

-

ABB Brand

-

Capacity:

-

300-400kg/h

-

Screw type:

-

Double-screw Co-rotating Screw

-

Key words:

-

Pp Hollow Sheet Making Machine

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

48:1

-

Screw Speed (rpm):

-

500 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS Mach

-

Voltage:

-

380v 50hz

-

Dimension(L*W*H):

-

30*10*5

-

Power (kW):

-

150

-

Weight:

-

15000

-

Product:

-

pp hollow sheet

-

L/D:

-

32-62

-

Raw material:

-

PP Granules/ Flakes

-

Usage:

-

Plastic Extrusion

-

Processing Type:

-

Exturding Machine

-

Automatic Grade:

-

Automatic Controll

-

Inverter:

-

ABB Brand

-

Capacity:

-

300-400kg/h

-

Screw type:

-

Double-screw Co-rotating Screw

-

Key words:

-

Pp Hollow Sheet Making Machine

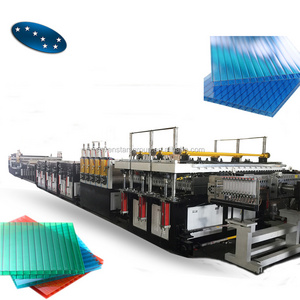

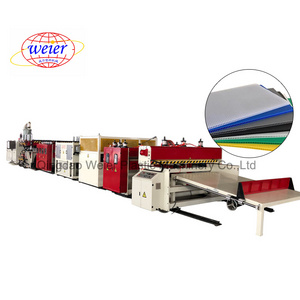

01 Machine Description:

1.The screw adopts the barrier type screw design, which is specially designed for PC and ABS melting.

2. It has less fine points, high yield and uniform plasticization, and vertical three-roll calender design.

3. The roller temperature can be adjusted by the mold temperature machine, and the surface gloss is high.

4. There is a laminating device, the customer can put any grain, the film is combined online, and the operation is convenient and easy to adjust.

5. The thickness of the sheet is positioned by a dial gauge, and the cutting is performed by an automatic meter cutting device.

02 Process principle:

Dehumidifying and drying of plastic pellets → Extruder: melting and plasticizing of raw materials → quick change filter → solution pump → distributor → extrusion die extrusion → three-roll calender → cooling setting device → trimming mechanism → traction Transfer → Shearing device

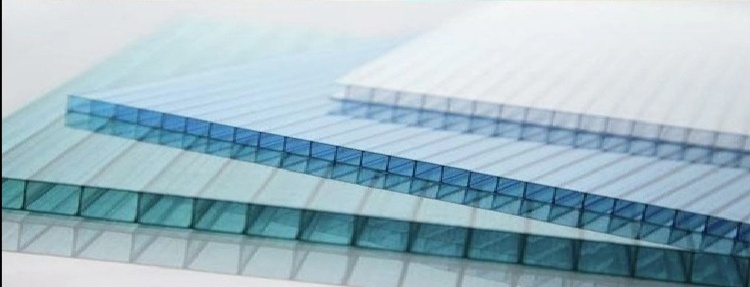

03 Product application:

Mainly used for travel bags, plastic molding, open air panels, weathering panels.

04 Machine Models:

| 1 | Equipment Model | 1000/1200 |

| 2 | Product Sheet Width | 800/1000mm |

| 3 | Product Sheet Thickness | 1.5-2.5mm |

| 4 | Maximum Line Speed | 3-10m |

Product Gallary

Nanjing GS-Mach Extrusion Equipment Co., Ltd is a professioanl mechanical design and manufacturing company, focusing on cutting-edge equipment such as plastics, rubber and chemicals Independent research and development and production.

The company adheres to the quality concept of excellence and follows the optimized management system. Finally, the GS-mach team will become a world-class manufacturing force of a famous brand.

Products have been sold in domestic and foreign countries, the Middle East, Southeast Asia, Europe and other countries. Company insists Customer benefits first, and provide customers with comprehensive technical support and after-sales training services.

Contact