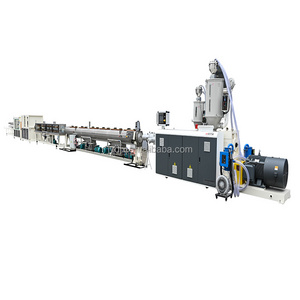

HDPE inspection well and pe hollow wall winding pipe machine production line - the perfect solution for your flexible

piping needs. The product is ideal for various applications and has a range of features that ensure its durability and

reliability. pe hollow wall winding pipe machine has been successfully used as a drainage pipe to replace cement pipes and cast iron pipes, and has broad market prospects. Ruite machinery is the professional manufacturer of large-diameter pe hollow wall winding pipe production lines. It has strong technical advantages and rich experience in implementation of production and installation.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ruite

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

26000x3500x2500

-

Power (kW):

-

90

-

Weight:

-

8500 KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

HDPE

-

spiral type pipes:

-

Spiral, Profiled, Corrugated, Inner Reinforced

-

spiral pipe usage1:

-

PE Water Sewer Pipe, Drainage Pipe

-

spiral pipe usage2:

-

Water Storage, Waste Water Treatment Tank

-

spiral pipe usage3:

-

Pickling Pool, Septic Tank, Fire Cistern

-

spiral pipe usage4:

-

Manhole Wells, Plastic Chamber

-

Machine name:

-

Spiral Winding Pipe Machine

-

pressure grade:

-

DN200-DN2400

-

HS Code:

-

8477209000

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ruite

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

26000x3500x2500

-

Power (kW):

-

90

-

Weight:

-

8500 KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

HDPE

-

spiral type pipes:

-

Spiral, Profiled, Corrugated, Inner Reinforced

-

spiral pipe usage1:

-

PE Water Sewer Pipe, Drainage Pipe

-

spiral pipe usage2:

-

Water Storage, Waste Water Treatment Tank

-

spiral pipe usage3:

-

Pickling Pool, Septic Tank, Fire Cistern

-

spiral pipe usage4:

-

Manhole Wells, Plastic Chamber

-

Machine name:

-

Spiral Winding Pipe Machine

-

pressure grade:

-

DN200-DN2400

-

HS Code:

-

8477209000

Product Description

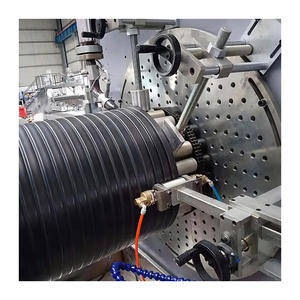

hollow wall winding pipe machine

|

Model

|

Pipe Dia.(mm)

|

Extruder model

|

Production speed m/h

|

Max.out put kg/h

|

Total power kw

|

Overall dimension mm

|

|

HRSG-800

|

200-800mm

|

SJ-75

SJ-45 |

1-30

|

200

|

180

|

17000*8000*4000

|

|

HRSG-1600

|

600-1600mm

|

SJ-90

SJ-65 |

1-20

|

500

|

220

|

20000*10000*4800

|

|

HRSG-2000

|

800-1200mm

|

SJ-120

SJ-90 |

1-18

|

700

|

260

|

22000*12000*5000

|

|

HRSG-3000

|

1500-3000mm

|

SJ-150

SJ-90 |

1-10

|

1000

|

310

|

25000*14000*5300

|

|

HRSG-4000

|

2000-4000mm

|

SJ-150

SJ-100 |

0.5-7

|

2000

|

310

|

40000*14000*5300

|

Detailed Images

Related Products

Company Introduction

Ruite specialize in providing advanced pe spiral winding pipe machine machinery for underground sewage construction or building usage. Ruite pe spiral winding pipe machine are used to create a variety of pipe types for different applications, such as hollow wall spiral winding, inner rib spiral winding, smooth wall winding, double plastic winding, and plastic insert steel winding. Ruite take pride in our expertise when it comes to larger diameter pipe machines, as it requires not only specialized machinery but also highly skilled professionals to operate them.

FAQ

1.

What is an HDPE hollow wall spiral winding machine?

---Firstly extrusion squre profile, then use a winding forming machine to shape large diameter, you can choose from 200mm-4000mm.

2. What are the features of an HDPE hollow wall spiral winding machine?

---High strength, good pressure resistance and impact resistance

3. What is the production capacity of an HDPE hollow wall spiral winding machine?

---Depend on model and pipe diameter sizes.

4 . How long does it take to manufacture an HDPE pipe using the machine?

---30-40 working days.

5 . What are the advantages of using an HDPE hollow wall spiral winding machine over traditional methods of pipe manufacturing?

---HDPE hollow wall spiral pipe has been successfully used as a drainage pipe to replace cement pipes and cast iron pipes.

---Firstly extrusion squre profile, then use a winding forming machine to shape large diameter, you can choose from 200mm-4000mm.

2. What are the features of an HDPE hollow wall spiral winding machine?

---High strength, good pressure resistance and impact resistance

3. What is the production capacity of an HDPE hollow wall spiral winding machine?

---Depend on model and pipe diameter sizes.

4 . How long does it take to manufacture an HDPE pipe using the machine?

---30-40 working days.

5 . What are the advantages of using an HDPE hollow wall spiral winding machine over traditional methods of pipe manufacturing?

---HDPE hollow wall spiral pipe has been successfully used as a drainage pipe to replace cement pipes and cast iron pipes.

6.

Can the machine produce pipes of different sizes and shapes?

---yes sure, we provide custom made service as per customer detail requirements.

---yes sure, we provide custom made service as per customer detail requirements.

7.

What is the maintenance cost of an HDPE hollow wall spiral winding machine?

---Machine can use 20 to 30 years, just change fast consumable parts.

---Machine can use 20 to 30 years, just change fast consumable parts.

8.

Does the machine require specialized training to operate it?

---easy operation, we support on site installation if customer need.

---easy operation, we support on site installation if customer need.

9.

Where can I buy an HDPE hollow wall spiral winding machine?

---from Qingdao comrise machinery co.,ltd

---from Qingdao comrise machinery co.,ltd

10

. Is there a warranty for the machine and what is the duration of the warranty?

---Machine 18months warranty, and lifetime technical consultant service.

---Machine 18months warranty, and lifetime technical consultant service.

Hot Searches