- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

10000

-

Weight (KG):

-

100 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DZJX

-

Voltage:

-

120V/220V/380V/440V/customization

-

Dimension(L*W*H):

-

customization

-

Power (kW):

-

1.5 kW

Quick Details

-

Barrel Volume (L):

-

1-10000L

-

Max. Loading Volume (L):

-

10000 L

-

Range of Spindle Speed(r.p.m):

-

20 - 30 r.p.m

-

Max. Loading Capacity:

-

10000

-

Weight (KG):

-

100 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DZJX

-

Voltage:

-

120V/220V/380V/440V/customization

-

Dimension(L*W*H):

-

customization

-

Power (kW):

-

1.5 kW

Product Description

DZJX

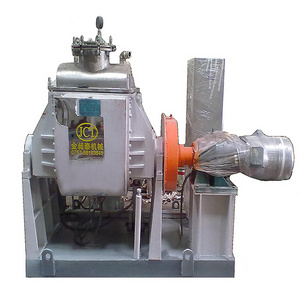

sigma mixer for hdpe/cellulose sigma mixer with extruder/z-blade mixer food

Sigma mixer is an ideal equipment for kneading, mixing, curing and polymerization of high viscosity and elastic-plastic materials. It can be used to produce silicone rubber, sealant, hot melt glue, food glue base, medicine preparation and so on.

Sigma mixer

is a special kind of mixture mixing equipment, the most commonly used is to use two Σ blade, using tangent type differential arranged side by side, namely an impeller speed, an impeller speed is slow, in order to produce the shear stress,different blade speed enables the mixing of the material to shear quickly, so that the material can be mixed evenly.

Products Show

* 5L laboratory type

Suitable for material research and development, quality and quality testing of small laboratory, can meet the material testing of 50L or less, with electric heating and vacuum function.

* 50L industrial production type

50L-500L are available in stock, and models of more than 500L can also be customized.

(Heating/water cooling/vacuumizing)

* Hydraulic overturn cylinder type

* The structure of the equipment is simple and compact, which can realize kneading and dumping of materials

* Screw extrusion type

* The material is extruded through the screw at the bottom of the chamber

* Vacuum type(-0.09MPA)

* It is especially suitable for mixing materials that react with air.

* Heating/cooling (jacket design)

* Mixing of materials for finished products requiring temperature environment.

Application

Sigma mixer especially suitable for

chewing gum

,

bubble gum

,

toothpaste

,

plastic

,

rubber

,

silicone rubber

,

dyes

,

pigments

,

printing ink

,

food gum base

,

pharmaceutical agents

,

architectural coatings

,

carbon

,

fine grain

,

high viscosity sealant

,

neuter glass glue

,

aluminum silver paste

,

silica gel

,

pulp

,

cellulose

,

battery slurry

,

dye

,

organic silicon resin

,

cosmetics

and other industries

Technical Parameter

|

Model

|

DZJX-2

|

DZJX-5

|

DZJX-10

|

DZJX-50

|

DZJX-100

|

DZJX-200

|

DZJX-300

|

DZJX-500

|

DZJX-1000

|

||||||||

|

Motor power(kw)

|

1.1-2.2

|

1.1-2.2

|

1.1-2.2

|

2.2-7.5

|

4-11

|

5.5-15

|

5.5-22

|

11-22

|

15-37

|

||||||||

|

capacity(L)

|

2

|

5

|

10

|

50

|

100

|

200

|

300

|

500

|

1000

|

||||||||

|

Heating way

|

Electrical,cycle steam/Hot oil/Hot water in jacket

|

|

|

|

|

|

|

|

|

||||||||

|

Steam Pressure(MPA)

|

usually 0.3(can add as requirement)

|

|

|

|

|

|

|

|

|

||||||||

|

Vacuum Degree(MPA)

|

-0.095(vacuum type)

|

|

|

|

|

|

|

|

|

||||||||

|

Pressure(MPA)

|

0.45(pressure type)

|

|

|

|

|

|

|

|

|

||||||||

|

Weight(KG)

|

150

|

200

|

300

|

600

|

1000

|

1800

|

2200

|

3000

|

4500

|

||||||||

Packing & Delivery

1. The inner packaging:stretch film; outer packaging:standard export fumigation-free wooden box

2. According to customer requirements

Hot Searches