- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Steel ball, spring, sealing ring

-

Products name:

-

Zero point locator

-

Material:

-

Stainless Steel

-

After-sales Service Provided:

-

Within the warranty period

-

advantages:

-

increase efficiency

-

Colour:

-

Metallic natural color

-

Function:

-

precise positioning

-

repeatability:

-

<0.005mm

-

Model size:

-

2/5/10/20/40

-

Usage:

-

Precision testing institutions in the field of mechanical processing

-

Hardness:

-

High precision, long lifespan, and high cost-effectiveness

Quick Details

-

Place of Origin:

-

Chongqing, China

-

Weight (KG):

-

4.2

-

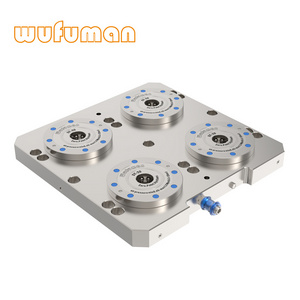

Brand Name:

-

CLAMPLTD

-

Core Components:

-

Steel ball, spring, sealing ring

-

Products name:

-

Zero point locator

-

Material:

-

Stainless Steel

-

After-sales Service Provided:

-

Within the warranty period

-

advantages:

-

increase efficiency

-

Colour:

-

Metallic natural color

-

Function:

-

precise positioning

-

repeatability:

-

<0.005mm

-

Model size:

-

2/5/10/20/40

-

Usage:

-

Precision testing institutions in the field of mechanical processing

-

Hardness:

-

High precision, long lifespan, and high cost-effectiveness

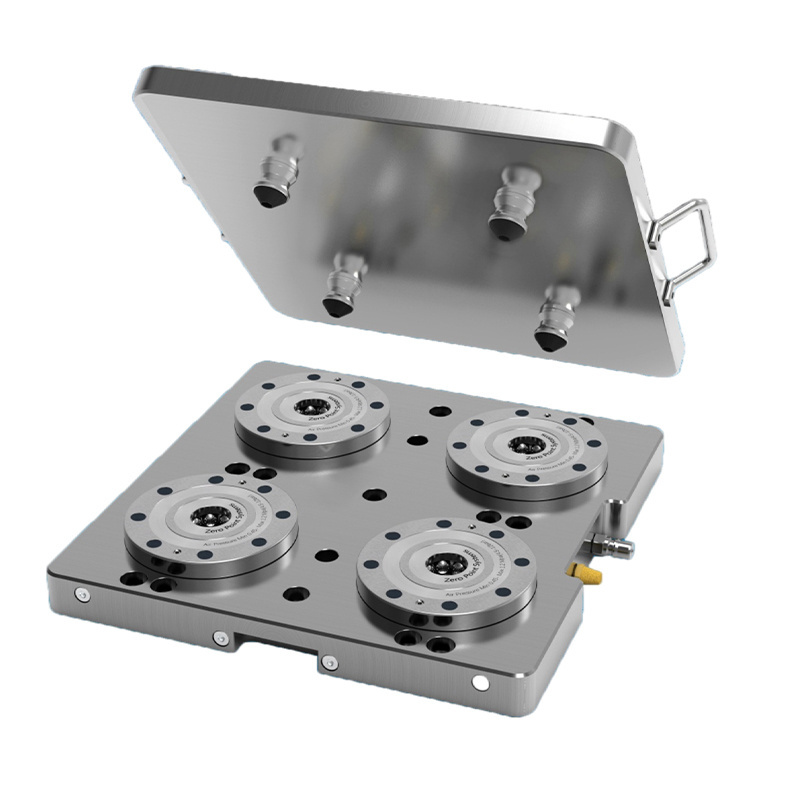

performance

The zero point quick locator can be used for quick changing pallets, quick changing fixtures, quick changing workpieces, and other occasions. The machining center can quickly change fixtures, with a repeated positioning accuracy of 0.002mm, a clamping force of 10.4 tons, a service life of 5 million times, and can improve the replacement speed of 90% of the fixtures.

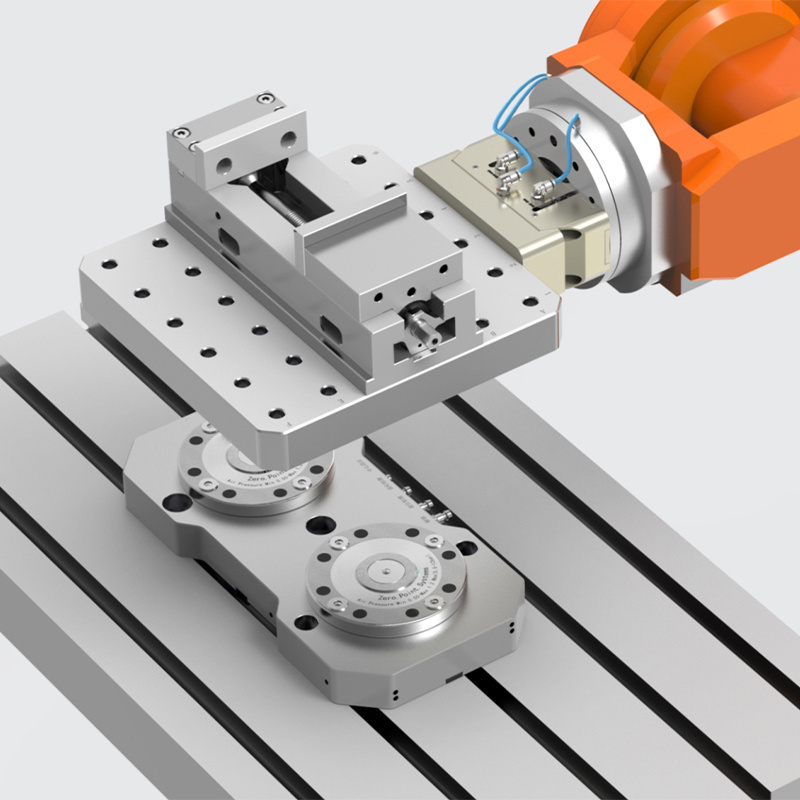

Application Scenario

Used for quick replacement of machine tool workbenches, pallets, fixtures, workpieces, etc., it can save 90% of the time for

changing fixtures, and the repeated positioning accuracy is less than 0.002mm. Improve the flexibility of the production line.

Applied in the automotive manufacturing industry, auxiliary workpiece positioning, aviation manufacturing industry, and machine

tool industry, it effectively reduces the auxiliary time during mechanical processing and can achieve five sided machining.

changing fixtures, and the repeated positioning accuracy is less than 0.002mm. Improve the flexibility of the production line.

Applied in the automotive manufacturing industry, auxiliary workpiece positioning, aviation manufacturing industry, and machine

tool industry, it effectively reduces the auxiliary time during mechanical processing and can achieve five sided machining.

Use zero point positioning pins to convert different types of product coordinate systems into coordinate systems, and then position and tighten them through standardized fixture interfaces on the machine tool. After ventilation, it acts on the spring plate, and the clamp plate is in an open state. The nail can be conveniently placed in the clamp plate, and when working, the air is cut off and clamped for processing. Therefore, there is no need to worry about unstable air pressure during work.

Mechanical clamping is provided through spring plates, compressed air is loaded to release the pull pin, and a pneumatic built-in installation type zero point locator is installed. The repeated positioning accuracy is 0.005mm, and the surface and piston are hardened. The clamping force of a single large model can reach 105KN, and the tensioning force can reach 40KN.

|

Product type

|

Model

|

Functional differentiation

|

|

Conventional type

|

ANC-5/10/20/40

|

Both conventional and zero point basic functions are available

|

|

With directional type

|

ANCD-5/10/20/40

|

Directional type with lateral anti rotation function, can be used as a single piece

|

|

Mini threaded installation type

|

ANC-2

|

The smallest model, different from other zero point installation methods, is installed using the thread provided by the body.Suitable for quick change devices with limited force and space

|

|

Automatic with lifting type

|

ANCZ-10/20

|

High degree of automation, with multiple functions such as central blowing, tray lifting, surface cleaning blowing, and

airtightness detection interface |

Hot Searches