- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

25-40 ton

-

Product name:

-

Chain Grate Stoker 10 Ton 12 Ton 13 Ton Steam Coal Fired Boiler For Ce

-

Steam Capacity:

-

2-25 t/h

-

Working Pressure:

-

1.0-2.5 MPa

-

Steam Temperature:

-

184-224 ℃

-

Feed Water Temp.:

-

20-105 ℃

-

Design fuel:

-

wood, straw, rice husk, biomass pellet etc

-

Material:

-

Boiler Steel

-

Thermal Efficiency:

-

≥ 88%

-

Color:

-

Can be Customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuji Boiler

-

Dimension(L*W*H):

-

Depends on Model

-

Weight:

-

25-40 ton

-

Product name:

-

Chain Grate Stoker 10 Ton 12 Ton 13 Ton Steam Coal Fired Boiler For Ce

-

Steam Capacity:

-

2-25 t/h

-

Working Pressure:

-

1.0-2.5 MPa

-

Steam Temperature:

-

184-224 ℃

-

Feed Water Temp.:

-

20-105 ℃

-

Design fuel:

-

wood, straw, rice husk, biomass pellet etc

-

Material:

-

Boiler Steel

-

Thermal Efficiency:

-

≥ 88%

-

Color:

-

Can be Customized

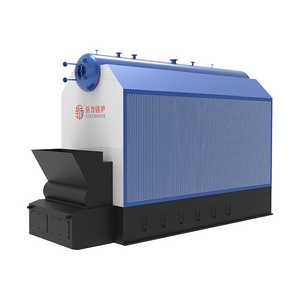

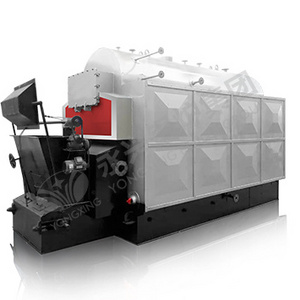

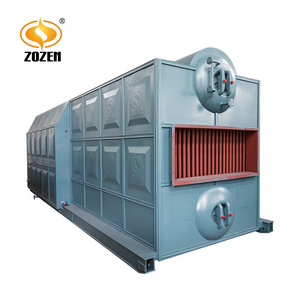

Chain Grate Stoker 10 Ton 12 Ton 13 Ton Steam Coal Fired Boiler For Cement Factory

Product features:

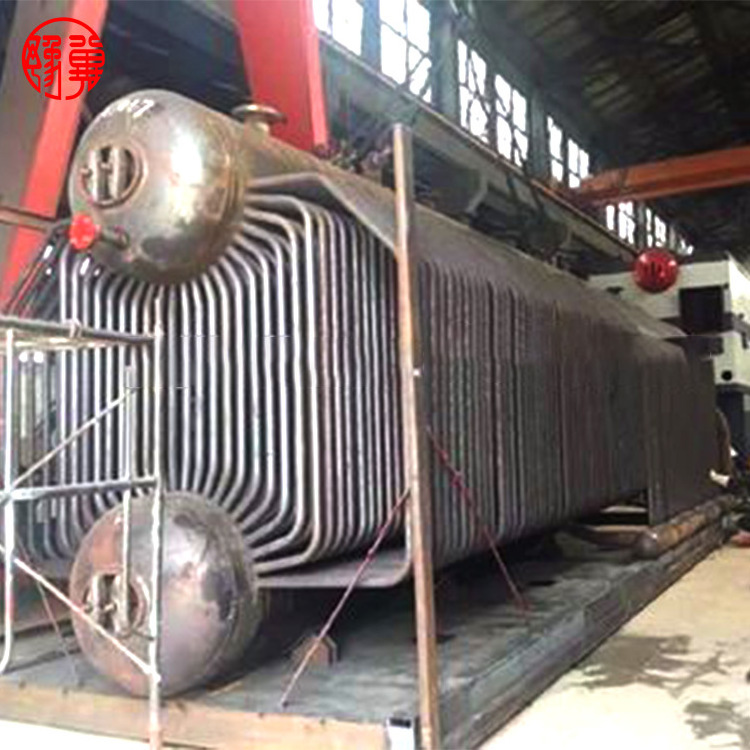

SZL series pressure double drum chain grate biomass hot water boiler, boiler host design as double boiler drum longitudinal layout, set steam water separating device in upper boiler drum, set periodic blow-off device in lower boiler drum, there are water cooling wall tubes at left and right side of furnace.

Use light chain grate add fuel automatically, the back of furnace is re-burning chamber, convection tubes, the tail of furnace is economizer or air preheater, equip with blower, draft fan for mechanical ventilation, and also equip with slag extractor for slagging automatically. Fuel fall down to chain grate and enter furnace for burning, the flue gas go through furnace, re-burning chamber, convection tubes, economizer or air preheater into tail flue, enter deduster, draft fan and chimney, and finally discharge into atmosphere.

sketch:

| SZL coal fired steam boiler | |||||||

| Model | Rated evaporation capacity (t/h) | Rated pressure (MPa) | Steam temperature (℃) | Thermal efficiency (%) | Fuel consumption(kg/h) | Size L×W×H (m) | Weight (t) |

| SZL4-1.25/1.6/2.5-AII | 4 | 1.25/1.6/2.5 | 193/204 | ≥83 | 591 | 7.5×2.65×3.5 | 32 |

| SZL6-1.25/1.6/2.5-AII | 6 | 1.25/1.6/2.5 | 193/204 | ≥83 | 884 | 7×2.7×3.5 | 21 |

| SZL10-1.25/1.6/2.5-AII | 10 | 1.25/1.6/2.5 | 193/204 | ≥83 | 1443 | 7.9×3.3×3.53 | 28 |

| SZL15-1.25/1.6/2.5-AII | 15 | 1.25/1.6/2.5 | 193/204 | ≥83 | 2157 | 10×3.2×3.5 | 30 |

| SZL20-1.25/1.6/2.5-AII | 20 | 1.25/1.6/2.5 | 193/204 | ≥83 | 2866 | 11×3.2×3.5 | 35 |

| SZL coal fired hot water boiler | ||||||

| Model | Rated power (mw) | Rated pressure (MPa) | Thermal efficiency (%) | Fuel consumption (kg/h) | Feed water temperature (℃) | Return water temperature (℃) |

| SZL1.4-0.7/95/70-AII | 1.4 | 0.7 | ≥83 | 300 | 95 | 70 |

| SZL2.8-0.7/95/70-AII | 2.8 | 0.7 | ≥83 | 590 | 95 | 70 |

| SZL4.2-1.0/95/70-AII | 4.2 | 1 | ≥83 | 880 | 95 | 70 |

| SZL5.6-1.0/95/70-AII | 5.6 | 1 | ≥83 | 1160 | 95 | 70 |

| SZL7-1.0/95/70-AII | 7 | 1 | ≥83 | 1450 | 95 | 70 |

| SZL10.5-1.0/95/70-AII | 10.5 | 1 | ≥83 | 2200 | 115 | 70 |

| SZL14-0.7/95/70-AII | 14 | 1 | ≥83 | 1160 | 115 | 70 |