- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

soap noodles making machine

-

Marketing Type:

-

New Product 2023

-

Capacity:

-

100/500/1000/2000/3000 KG/H

-

Raw Material:

-

Palm Oil

-

Advantage:

-

High Efficiency Automatic Working

-

Kw:

-

15kw

-

Voltage:

-

220V/380V

Quick Details

-

Place of Origin:

-

Henan China

-

Brand Name:

-

Taion

-

Weight (KG):

-

1200

-

Machine Type:

-

soap noodles making machine

-

Marketing Type:

-

New Product 2023

-

Capacity:

-

100/500/1000/2000/3000 KG/H

-

Raw Material:

-

Palm Oil

-

Advantage:

-

High Efficiency Automatic Working

-

Kw:

-

15kw

-

Voltage:

-

220V/380V

Product description

This saponification machine is used to make soap base with animal or vegetable oil/ fat and Industrial caustic soda.

Then its end product will be put into the soap making line to make soaps.

Its major operation is manual type. This type is suitable for small capacity production that is about 200-500kg/batch.

The soap machine is made of stainless steel 304 and consisted of saponification tank, measure tank, boiler, platform, soap storage tank, cooling tank, tools, manual stamping machine, cutting blade, stamping table .

It is easy to operate and maintain.

Delivery time: 40 working days after we get your advance payment.

Then its end product will be put into the soap making line to make soaps.

Its major operation is manual type. This type is suitable for small capacity production that is about 200-500kg/batch.

The soap machine is made of stainless steel 304 and consisted of saponification tank, measure tank, boiler, platform, soap storage tank, cooling tank, tools, manual stamping machine, cutting blade, stamping table .

It is easy to operate and maintain.

Delivery time: 40 working days after we get your advance payment.

Vacuum drying chamber 8000 kg/h of toilet soap noodles or low TFM laundry soap noodles (water content of the soap noodles is around 28%) can be produced. All metallic parts in contact with soap are in stainless steel 304.Diameter of chamber: 1700 mm, max.ovalness is 1 mm. Diameter of main shaft:110 mm.Motor Power: 7.5 KWShaft speed: 14 r/min The speed reducers are supplied by Fender, Germany.

VSD vacuum dryer chamber can produce toilet soap noodles (Moisture of the soap noodles: from11% to 28%) All metallic parts in contact with soap are in stainless steel 304 or stainless steel 316L. The sealing of soap feeding nozzle are realized by rotating seal and Tension mechanical.

VSD vacuum dryer chamber can produce toilet soap noodles (Moisture of the soap noodles: from11% to 28%) All metallic parts in contact with soap are in stainless steel 304 or stainless steel 316L. The sealing of soap feeding nozzle are realized by rotating seal and Tension mechanical.

Product Specifications

|

Constitute

|

Machine

|

|

Oil sink

|

2m3, carbon steel

|

|

Brine sink

|

1m3, carbon steel

|

|

Causic soda sink

|

1m3, carbon steel

|

Process of production line

What parts does the soap production line consist of?

1. Mixer, used to mix raw materials

2. Three-roll mill for rubbing soap material

3. Semi-finished product conveyor for conveying soap flakes

4. Twin-screw vacuum layering machine for vacuum layering

5. Printing and cutting machine for cutting and printing

6 Product conveying, for conveying products

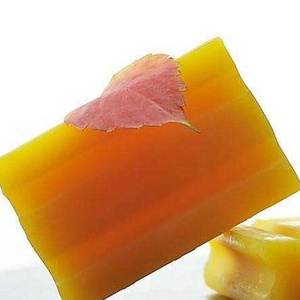

soap product

Related Products

Our clients

Contact us

Hot Searches