- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FURIS

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Plastic tube filling and sealing machine

-

Operation:

-

Touch Screen

-

Power Supply:

-

220V/380V,1phase,3phase can customize

-

Machine capacity:

-

max 80pcs per min

-

After Warranty Service:

-

Spare parts

-

Certification:

-

CE Certification

-

Marketing Type:

-

New Product 2022

Quick Details

-

Packaging Type:

-

Tube

-

Packaging Material:

-

Plastic, Metal

-

Driven Type:

-

Pneumatic

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FURIS

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Plastic tube filling and sealing machine

-

Operation:

-

Touch Screen

-

Power Supply:

-

220V/380V,1phase,3phase can customize

-

Machine capacity:

-

max 80pcs per min

-

After Warranty Service:

-

Spare parts

-

Certification:

-

CE Certification

-

Marketing Type:

-

New Product 2022

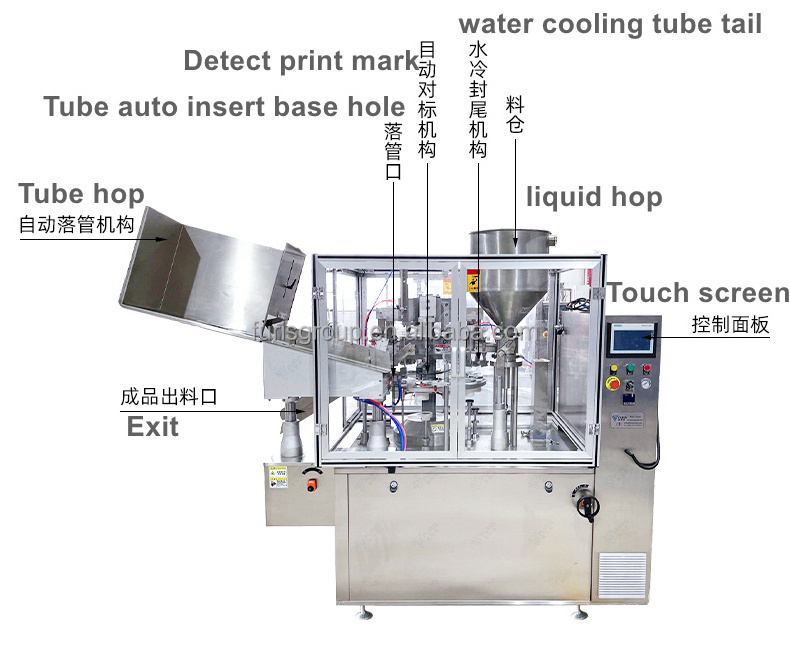

Product Overview

Furis Machinery Group is a cosmetic personal care product making and packing machine supplier,we can offer the detergent pod making machine, automatic tube filling sealing machine,bath bomb press and packing machine,etc we have more than 10 year experience in this area,we offer manual semi auto full auto bath bomb press machine and full auto bath bomb wrap machine to meet different customer with different capacity inquiry.Our machines mainly export to the Malaysia, United Arab Emirates, Saudi Arabia,India,United Kingdom, Poland, Italy, Spain, New Zealand, Thailand, South Korea, Belgium, France, Denmark,Australia,Hungary,Switzerland, Czech Republic, Germany, Latvia, Russia, Canada, United States more than 20 country.Welcome to OEM and distribute our machine in local place.

Product Feature

This tube filling sealing machine is used for filling lotion into the tube and sealing plastic/laminated Alu tube

auto.through change the mold our machine can be used for plastic and alu tube both.

auto.through change the mold our machine can be used for plastic and alu tube both.

1.Transmission parts enclosed in the platform below the safe, reliable, non-polluting; filling and

sealing part of the installation within the platform above a semi-closed static-frame visual plexiglass cover, easy to observe,easy to operate, easy to maintain;

2.Main parts adopt import parts, PLC control system (Siemens), color touch screen dispaly (Siemens), invertor: (Siemens), low

electric applicator (Schneider), pneumatic parts (Airtac, Taiwan)

3.Automatically feeding tube into tube holder,with 12 working station,the machine max speed can fill 60pcs tube per min

4.The photoelectric target-aiming working station employs accurate detector and marching type motor,ensuring the tube design at the correct position.

5.Filling nozzle enters tube inside to fill.As it fills it will moves up and prevent material from over flowing and spilling.

Has auto cutting tube tail function when finishing fill the material into the tube.

6.No tube no filling,Sealing temperature adopt (Leister hot air gun) inside heating for the tail of tube and cooling device for

out of tube.

7.Automatically printing the character code on the tube bottom.

8.Has overload protection

9. Has accounting and auto stop machine when reach the number

sealing part of the installation within the platform above a semi-closed static-frame visual plexiglass cover, easy to observe,easy to operate, easy to maintain;

2.Main parts adopt import parts, PLC control system (Siemens), color touch screen dispaly (Siemens), invertor: (Siemens), low

electric applicator (Schneider), pneumatic parts (Airtac, Taiwan)

3.Automatically feeding tube into tube holder,with 12 working station,the machine max speed can fill 60pcs tube per min

4.The photoelectric target-aiming working station employs accurate detector and marching type motor,ensuring the tube design at the correct position.

5.Filling nozzle enters tube inside to fill.As it fills it will moves up and prevent material from over flowing and spilling.

Has auto cutting tube tail function when finishing fill the material into the tube.

6.No tube no filling,Sealing temperature adopt (Leister hot air gun) inside heating for the tail of tube and cooling device for

out of tube.

7.Automatically printing the character code on the tube bottom.

8.Has overload protection

9. Has accounting and auto stop machine when reach the number

Product Paramenters

|

1

|

Model

|

FRS-80

|

FRS-60

|

FRS-50

|

FRS-40

|

|

2

|

Voltage

|

220V/380V 50-60Hz

|

220V/380V 50-60Hz

|

220V/380V 50-60Hz

|

220V/380V 50-60Hz

|

|

3

|

Productivity

|

40-80 pcs/min

|

40-60 pcs/min

|

30-50 pcs/min

|

30-40 pcs/min

|

|

4

|

Filling volume

|

5-300ml

|

5-300ml

|

5-300ml

|

5-300ml

|

|

5

|

Tube diameter

|

10-50mm

|

10-50mm

|

10-50mm

|

10-50mm

|

|

6

|

Tube length

|

50-250mm

|

50-250mm

|

50-250mm

|

50-250mm

|

|

7

|

Max power

|

3kw

|

3kw

|

3kw

|

2.5kw

|

|

8

|

Working station

|

12

|

12

|

8

|

8

|

|

9

|

Water consumption

|

3-6L/Min

|

3-6L/Min

|

3-6L/Min

|

3-6L/Min

|

|

10

|

Machine weight

|

2100kg

|

2100kg

|

1600kg

|

1000kg

|

|

11

|

Dimension(L*W*H)

|

1900*800*1600mm

|

1900*800*1600mm

|

1500*600*1500mm

|

1400*600*1300mm

|

Customer Photos

Hot Searches