- Product Details

- {{item.text}}

Quick Details

-

Welding Mode:

-

rolling welding

-

Welding Diameter:

-

1mm

-

Use:

-

seam welding

-

Voltage:

-

380v

-

Weight (KG):

-

650 KG

-

Power (kW):

-

150

-

Rated Power:

-

200KVA

-

Rated Voltage:

-

380v

-

Rated Frequency:

-

50/60HZ

-

Max Short Current:

-

26000A

-

Electrode Stroke:

-

5mm

-

Welding Speed:

-

0.5-4m/min

-

Electrode Pressure:

-

6.2KN

-

Cooling Water Flow:

-

60L/min

-

Weight:

-

1150KG

-

Motor Power:

-

150w

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOBO

-

Forming Time:

-

0.5-2.5s

-

Welding Mode:

-

rolling welding

-

Welding Diameter:

-

1mm

-

Use:

-

seam welding

-

Voltage:

-

380v

-

Weight (KG):

-

650 KG

-

Power (kW):

-

150

-

Rated Power:

-

200KVA

-

Rated Voltage:

-

380v

-

Rated Frequency:

-

50/60HZ

-

Max Short Current:

-

26000A

-

Electrode Stroke:

-

5mm

-

Welding Speed:

-

0.5-4m/min

-

Electrode Pressure:

-

6.2KN

-

Cooling Water Flow:

-

60L/min

-

Weight:

-

1150KG

-

Motor Power:

-

150w

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

Product Description

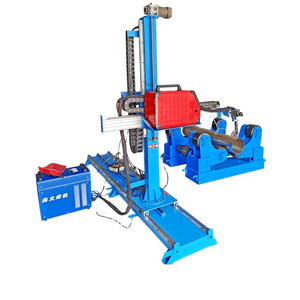

Automatic longitudinal tank and barrel circular roller seam welding machine

Seam welding machine means that the weldment is assembled into a lap or butt joint and placed between two roller electrodes. The roller electrode pressurizes the weldment and rotates, and continuously pulses power to form a continuous weld.

Feature

1. Contains two standard models: horizontal seam seam welding machine and longitudinal seam seam welding machine;

2. A machine can also have both transverse seam welding and longitudinal seam welding. As long as you change the direction of the upper electrode wheel and change the lower electrode arm, you can easily switch between the two welding methods;

3. The single wheel is driven by three-phase stepless speed regulation, the welding speed is convenient to adjust, and the tangent speed of the upper and lower wheels is consistent;

4. Adopt adjustable stroke cylinder for pressure to avoid collision and damage of upper and lower electrodes;

5. It is widely used in metal manufacturing and processing industries such as hardware, home appliances, automobiles, motorcycle fuel tanks, basins, sinks, cans, etc.

2. A machine can also have both transverse seam welding and longitudinal seam welding. As long as you change the direction of the upper electrode wheel and change the lower electrode arm, you can easily switch between the two welding methods;

3. The single wheel is driven by three-phase stepless speed regulation, the welding speed is convenient to adjust, and the tangent speed of the upper and lower wheels is consistent;

4. Adopt adjustable stroke cylinder for pressure to avoid collision and damage of upper and lower electrodes;

5. It is widely used in metal manufacturing and processing industries such as hardware, home appliances, automobiles, motorcycle fuel tanks, basins, sinks, cans, etc.

Details Images

Specification

|

Mold

|

Rated Capacity

|

Voltage

|

Frequency

|

Short Current

|

Welding Speed

|

Electrode

Pressure

|

Motor Power

|

Power

|

Weight

|

|

|

KVA

|

V

|

Hz

|

A

|

M/min

|

KN

|

V

|

W

|

kg

|

|

FN-50

|

50

|

380

|

50/60

|

15000

|

0.6-2

|

2.5

|

3-380

|

90

|

500

|

|

FN-75

|

75

|

380

|

50/60

|

18000

|

0.6-2

|

3.9

|

3-380

|

150

|

650

|

|

FN-100

|

100

|

380

|

50/60

|

20000

|

0.6-2

|

4.7

|

3-380

|

150

|

880

|

|

FN-150

|

150

|

380

|

50/60

|

26000

|

0.6-2

|

6.1

|

3-380

|

150

|

1050

|

|

FN-200

|

200

|

380

|

50/60

|

31000

|

0.6-2

|

6.1

|

3-380

|

150

|

1250

|

Hot Searches