- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

MINGTAI

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

16000*1100*1200

-

Weight:

-

10T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Video technical support

-

Product name:

-

Floor deck forming machine

-

Usage:

-

Rainwater downspour

-

Color:

-

Client's Request

-

Raw material:

-

Color Steel Sheet

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Plc:

-

DELTA(TAIWAN)or Mitsubishi(JAPAN)

-

Pump:

-

7.5KW

-

Certification:

-

CE ISO

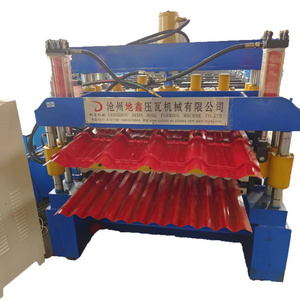

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

0-8m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

MINGTAI

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

16000*1100*1200

-

Weight:

-

10T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Video technical support

-

Product name:

-

Floor deck forming machine

-

Usage:

-

Rainwater downspour

-

Color:

-

Client's Request

-

Raw material:

-

Color Steel Sheet

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Plc:

-

DELTA(TAIWAN)or Mitsubishi(JAPAN)

-

Pump:

-

7.5KW

-

Certification:

-

CE ISO

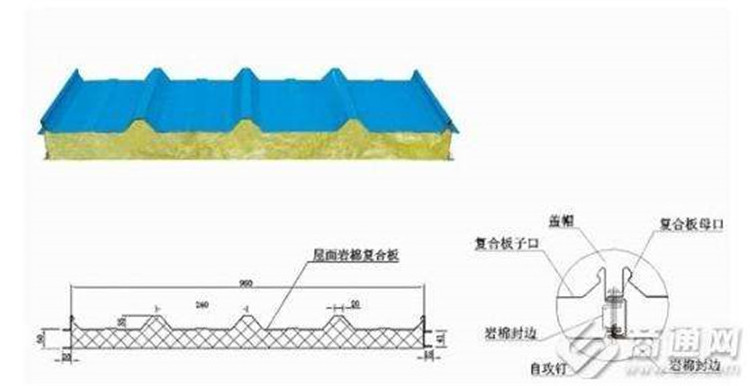

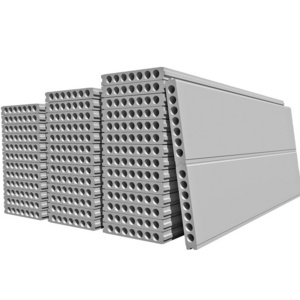

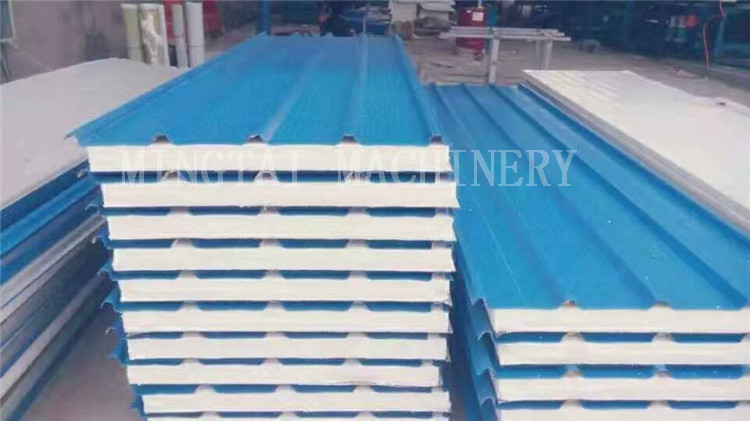

High Quality Automatic EPS 3D Panel Wall Panel Roll Forming Machine

(1). Brief Introduction

The Roof Panels made by our Roll Forming Machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas.

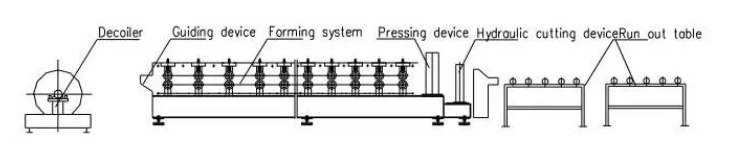

(2). Working Flow of Roll Forming Machine

Decoiling the sheet-Sheet guiding-Roll forming-Measure length-Cutting the panel-Panels to the supporter

(3).Technical Detail

|

No |

High Quality Automatic EPS 3D Panel Wall Panel Roll Forming Machine |

|

|

1 |

Dimensions (L*W*H) |

36*2.25*2.5m |

|

2 |

Power |

Main motor power: -4kw Flying saw power: -2*0.75kw |

|

3 |

Total power |

30kw |

|

4 |

Rows of forming rollers |

13 rows |

|

5 |

Rows of glue rollers |

23 rows |

|

6 |

Weight |

11t |

|

7

|

Voltage |

380V/50—60Hz |

|

8 |

Capacity |

4m/min |

|

9 |

Control system |

PLC Control |

|

10 |

Operating staff |

6 (4-5 staff for key process) |

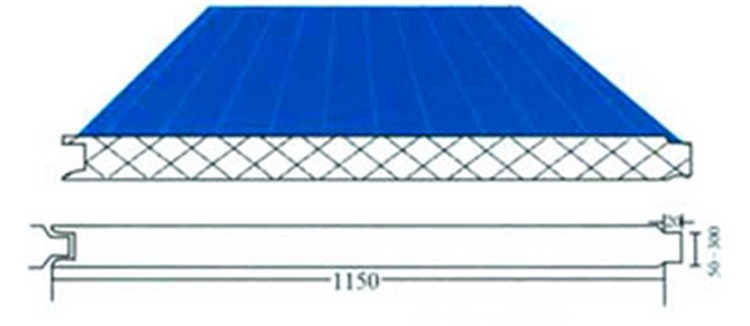

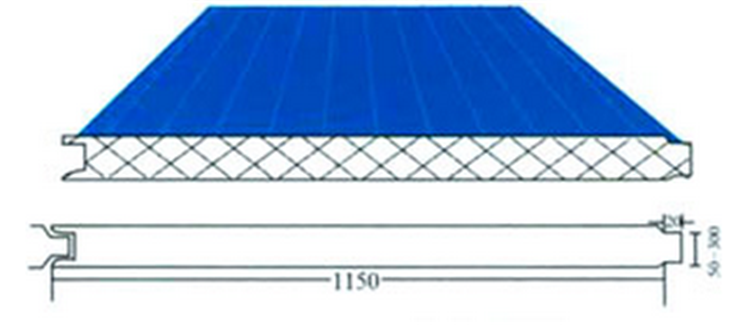

4) Parameters of the panel

|

No |

|

|

|

1 |

Finished sandwich panel |

EPS sandwich panel |

|

2 |

Steel Coil Width |

1000mm, 1200mm, 1250mm |

|

3 |

Thickness of the panel |

50-300mm |

|

4 |

Thickness of steel |

0.28-0.8mm |

|

5 |

Panel length |

1000-12000mm, adjustable |

|

6 |

Capacity |

>=600,000m2 per year |

5)Our advantages

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .to protect surface shiniing and strong

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.and hardness 60 degree.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine. Rollers are CNC processed to ensure precision performance.

5 .automatic PLC : introduced Mitsubishi PLC with touch screen ,inverter,transformer.

6. powerful driving system: big inch train,or gear box driving system.

7

. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

Packing

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.