- Product Details

- {{item.text}}

Quick Details

-

Fire-proof rate::

-

A-class incombustible (GB8624-1997)

-

Incombustibility::

-

180 minutes (GB/T9978-1999)

-

Moisture::

-

<10%

-

Heat conduction::

-

0.24W/MK (Jc/t564) Average

-

Sound-absorption::

-

45db (GBJ75-84)

-

Anti-bend strength::

-

>16MPa (GB/T7019-1997)

-

Moisture movement rate::

-

<0.19% (GB/T7019-1997)

-

Dry shrinking rate::

-

<0.09% (GB/T7019-1997)

Quick Details

-

Place of Origin:

-

Shandong, China

-

Materials::

-

Tobermorite, Portland cement, Quartz sand, cellulose fiber and so on

-

Density::

-

1.30-1.50g/cm3

-

Fire-proof rate::

-

A-class incombustible (GB8624-1997)

-

Incombustibility::

-

180 minutes (GB/T9978-1999)

-

Moisture::

-

<10%

-

Heat conduction::

-

0.24W/MK (Jc/t564) Average

-

Sound-absorption::

-

45db (GBJ75-84)

-

Anti-bend strength::

-

>16MPa (GB/T7019-1997)

-

Moisture movement rate::

-

<0.19% (GB/T7019-1997)

-

Dry shrinking rate::

-

<0.09% (GB/T7019-1997)

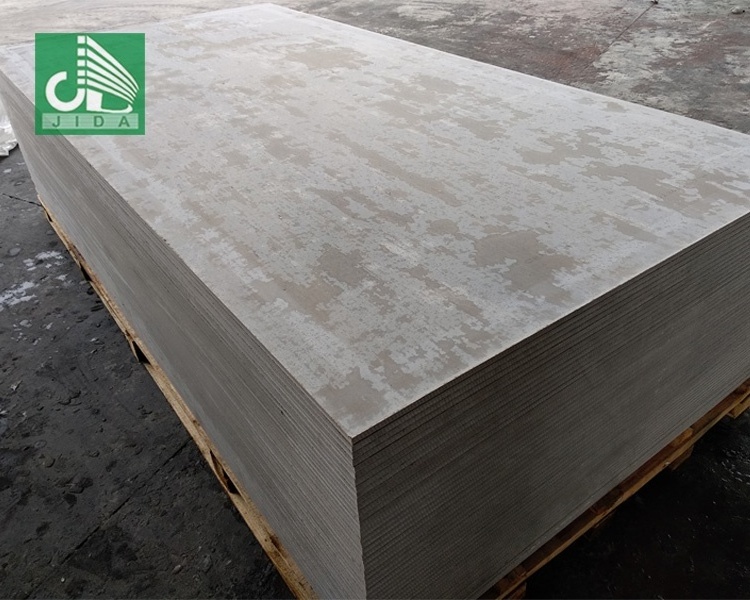

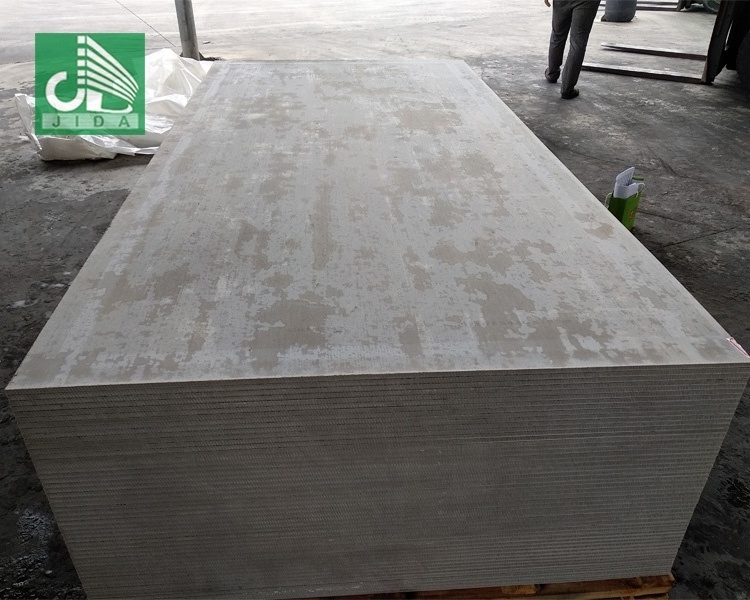

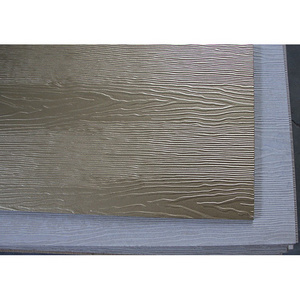

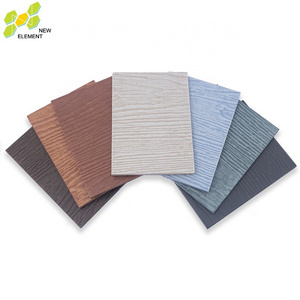

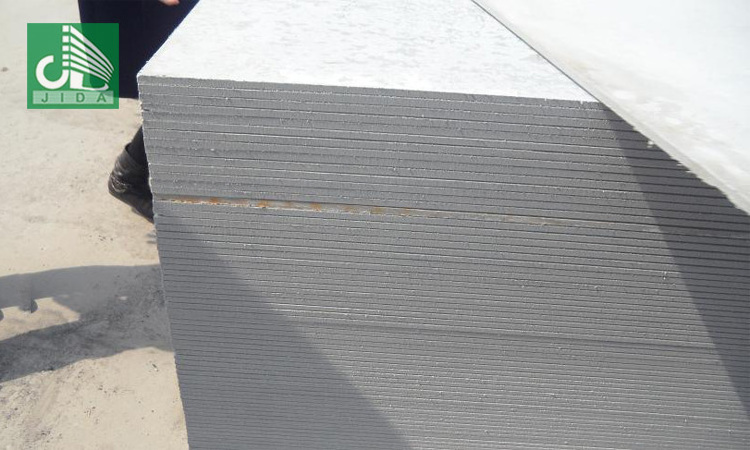

Fiber Cement Board is mainly made of Portland cement and silicate materials as base and cellulose reinforced, forming in Hatschek process and high pressure (4000T press machine for 15 minutes) and fumigation (in autoclave for 24 hours), so it has the advantages of high strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption, no distortion and no radiation...Etc.

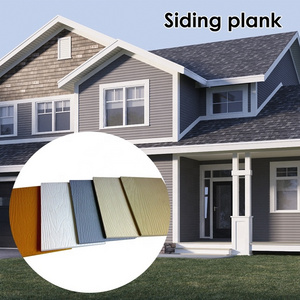

Used as suspended ceiling, partition, heat insulating board, base plate, billboard, external wall panel, exterior wall cladding, paneling, moving floor, desktop board, fire-resistant air pipe, back-liners, skirting lines, prefabricated structures, door shutters…etc.

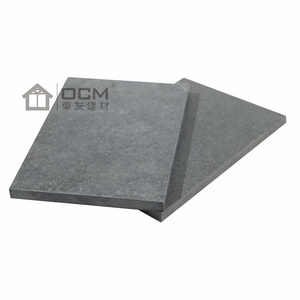

| Fiber Cement Board | |

| Materials: | Tobermorite, Portland cement, Quartz sand, cellulose fiber and so on |

| Fire-proof rate: | A-class incombustible (GB8624-1997) |

| Incombustibility: | 180 minutes (GB/T9978-1999) |

| Density: | 1.3-1.6g/cm3 |

| Moisture: | <10% |

| Heat conduction: | 0.24W/MK (Jc/t564) Average |

| Sound-absorption: | 45db (GBJ75-84) |

| Anti-bend strength: | >16MPa (GB/T7019-1997) |

| Moisture movement rate: | <0.19% (GB/T7019-1997) |

| Dry shrinking rate: | <0.09% (GB/T7019-1997) |

| Radiation rate: | According with Standard (GB6566-2000) |

1. Non-pollution:

no asbestos, no VOC gas producing, and no radiation.

2. Fireproof:

of inflammable grade A; complying with BS 476 Part4\ Part6\ Part7; releasing no toxic gas; zero smoke coefficient.

3. Economical:

light but with high intensity, reducing construction costs.

4. Waterproof and damp proof:

tobermorite crystal structure as its main structure, which ensures its excellent property and less affection from humidity.

5. Heat insulation:

with good heat insulation performance so that energy consumption can be lowered.

6. Long-service life:

it is convenient for decoration to use inorganic base materials such as cement and konilite, which produce no pollution and their service life is as long as that of brick. Aimite panel is resistant to mildew, moth, and aging.

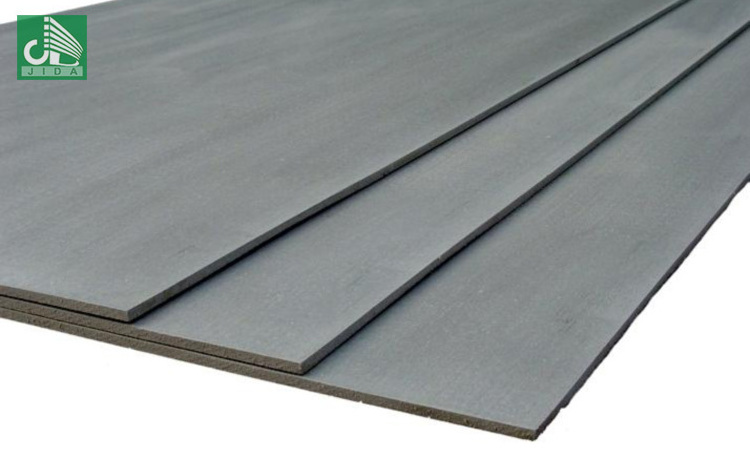

1. Main application:

partition wall and ceiling

2. Fireproof structure:

fireproof wall, door and furniture.

3. Heat insulation structure:

internal heat insulation layer and heat insulation of outer wall.

4. Sound insulation structure:

cinema, meeting hall, music hall, etc, for example.

5. Wet areas:

basement, toilet, kitchen as well as other environment of low temperature and corrosion.

6. Backing-up structure:

best used as filling plate of screen wall. We have developed supporting system of backing-up plate for renowned units of screen wall construction.

7. Other purposes:

applied to furniture, movable floorboard, and office dividing wall.

1 . We draw the installation guideline to define the fixing position, the center distance is 1200mm.

2 . USe UC type keel hang fitting to link and fix the room and key keel, keep the key keel horizontal.

3 . Use the caliper to vertically fix the sub keel on key keel,the center distance of the sub keels is 611mm.

4 . TO install the horizontal keels as per the request,is center distance is 1222mm.

5 . Use the tapping screw fix the woersen board on the sub-keel and do the treatment of the seam connection.