- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

4500 r.p.m

-

Spindle Bore(mm):

-

56mm

-

Width of bed (mm):

-

32 mm

-

Spindle Motor Power(kW):

-

7KW(30min/cont)

-

Travel (X Axis)(mm):

-

185 mm

-

Travel (Z Axis)(mm):

-

570 mm

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

2313x2440x1830

-

Brand Name:

-

LeyanTTS

-

Model Number:

-

EET150/500

-

Weight (KG):

-

4200

-

Max. swing dia.:

-

536mm

-

Max. processing dia.:

-

330mm

-

Max. processing length:

-

530mm

-

Spindle structure:

-

Belt spindle

-

Spindle end form:

-

A2-6

-

Chuck:

-

8(optional 10)

-

Turret form:

-

Servo Dota

-

Tools capacity:

-

8(optional 12)

-

Turning tool body size:

-

25(optional 20)

-

Turret indexing time(180 deg)sec:

-

0.2 sec/step

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

530

-

Year:

-

least date

-

Max. Spindle Speed (r.p.m):

-

4500 r.p.m

-

Spindle Bore(mm):

-

56mm

-

Width of bed (mm):

-

32 mm

-

Spindle Motor Power(kW):

-

7KW(30min/cont)

-

Travel (X Axis)(mm):

-

185 mm

-

Travel (Z Axis)(mm):

-

570 mm

-

Place of Origin:

-

Zhejiang, China

-

Dimension(L*W*H):

-

2313x2440x1830

-

Brand Name:

-

LeyanTTS

-

Model Number:

-

EET150/500

-

Weight (KG):

-

4200

-

Max. swing dia.:

-

536mm

-

Max. processing dia.:

-

330mm

-

Max. processing length:

-

530mm

-

Spindle structure:

-

Belt spindle

-

Spindle end form:

-

A2-6

-

Chuck:

-

8(optional 10)

-

Turret form:

-

Servo Dota

-

Tools capacity:

-

8(optional 12)

-

Turning tool body size:

-

25(optional 20)

-

Turret indexing time(180 deg)sec:

-

0.2 sec/step

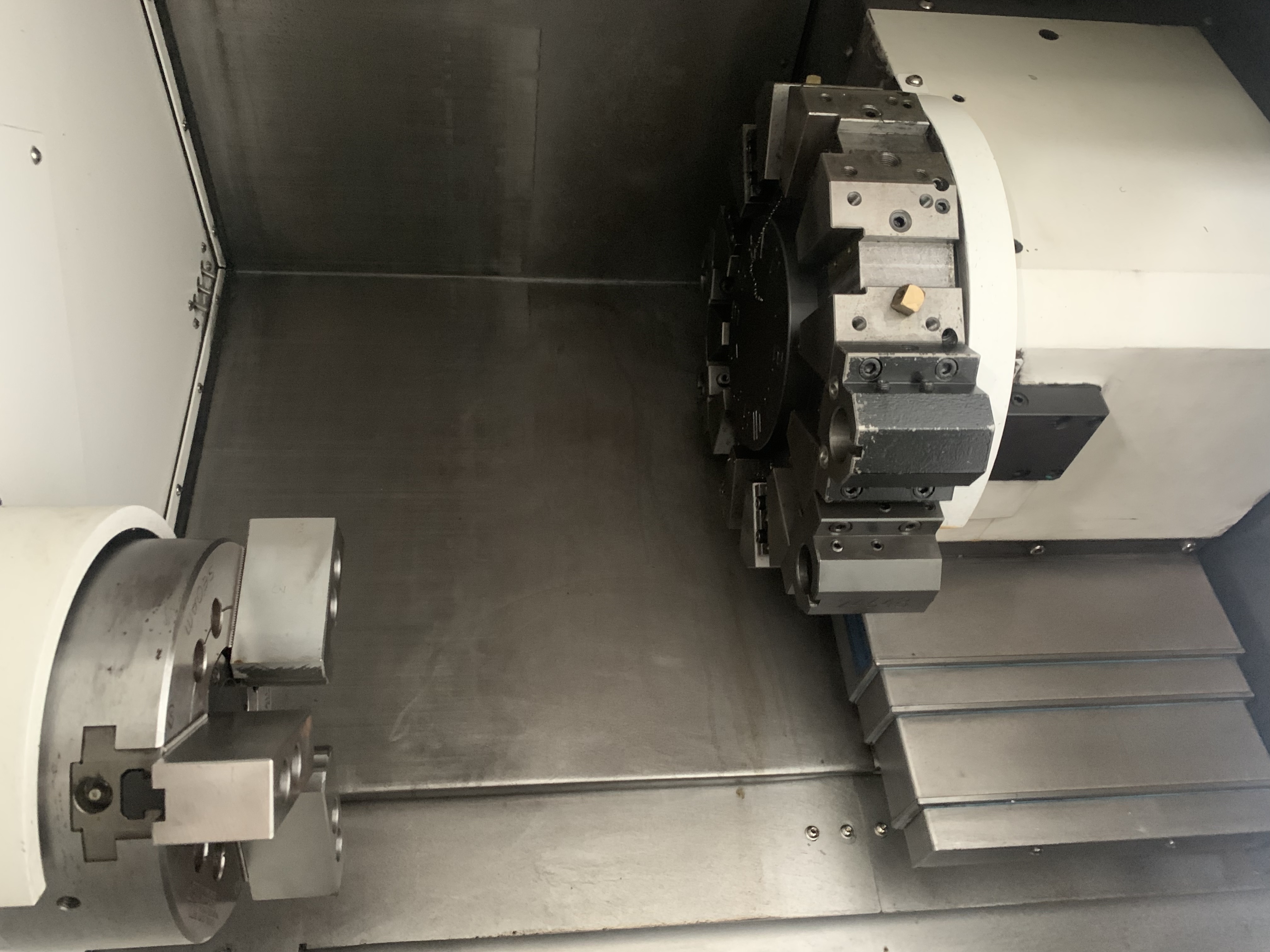

Product Description

|

ITEM

|

SPECIFICATIONS

|

EET150/300

|

EET150/500

|

|

|

Processing Capacity

|

Max. swing dia.

|

536mm

|

536mm

|

|

|

|

Max. processing dia.

|

330mm

|

330mm

|

|

|

|

The distance between end face (spindle to turret )

|

115-400mm

|

125-695mm

|

|

|

|

Max. processing length

|

285mm

|

530mm

|

|

|

Spindle

|

Output power(30mins/continous)

|

7kw(optional 12)

|

7kw(optional 12)

|

|

|

Spindle

|

Spindle structure

|

Belt spindle

|

Belt spindle

|

|

|

|

Spindle end form

|

A2-6

|

A2-6

|

|

|

|

Spindle speed

|

4500rpm

|

4500rpm

|

|

|

|

Chuck

|

8 in(optional 10)

|

8 in(optional 10)

|

|

|

|

Through spindle hole diameter

|

φ62mm

|

φ62mm

|

|

|

|

Bar material passing capacity

|

φ51mm

|

φ51mm

|

|

|

|

C axis(interpolation linkage axis)indexing

|

-

|

-

|

|

|

Transfer System

|

X axis travel

|

185mm

|

185mm

|

|

|

|

Z axis travel

|

325mm

|

570mm

|

|

|

|

X axis fast forward speed

|

30m/min

|

30m/min

|

|

|

|

Z axis fast forward speed

|

36m/min

|

36m/min

|

|

|

Turret

|

Turret form

|

Servo Dota

|

Servo Dota

|

|

|

|

Tools capacity

|

8ea(optional 12)

|

8ea(optional 12)

|

|

|

|

Turret indexing time(180 deg)sec

|

0.2sec/step

|

0.2sec/step

|

|

|

|

Turning tool body size

|

25mm(optional20)

|

25mm(optional20)

|

|

|

|

Max. boring bar dia.

|

φ40mm(optionalφ32)

|

φ40mm(optionalφ32)

|

|

|

|

Miling shaft power

|

-

|

|

|

|

|

Milling shaft speed

|

-

|

|

|

|

Tailstock

|

Form

|

Automatic hydraulic tailstock

|

|

|

|

|

Taper hole form

|

MT4

|

|

|

|

|

Body moving stroke

|

300mm

|

|

|

|

|

Body moving speed

|

10m/min

|

|

|

|

Coolant system

|

Water tank volume

|

180L

|

225L

|

|

|

|

Water pump motor

|

750W

|

|

|

|

|

Rated flow range

|

1.5~7m³/h

|

|

|

|

|

Head range

|

19~38m

|

|

|

|

Power supply

|

Power source(continuous)

|

21KVA

|

27KVA

|

|

|

|

Power requirements

|

3φ380V±10%V

|

|

|

|

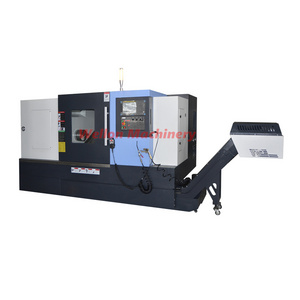

Size and weight

|

Area(without chip conyeyor)

|

2271(L)*2440(W)*1830(H)

|

2313(L)*2440(W)*1830(H)

|

|

|

|

Area(back-out chip conveyor)

|

2271(L)*4360(W)*1830(H)

|

2313(L)*4360(W)*1830(H)

|

|

|

|

Area(side out chip conveyor)

|

4541(L)*2438(W)*1830(H)

|

4913(L)*2438(W)*1830(H)

|

|

|

|

Net weight

|

3800kg

|

4200kg

|

|

|

Others

|

Ambient temperature

|

0~40℃

|

0~40℃

|

|

|

|

Relative humidity

|

≤85%

|

|

|

Features:

1. Flexible, high-performance automated machine tools, representing the development direction of modern machine tool ontrol technology, is a typical mechatronics products.

2.B

etter solve the complex, precision, small batch, multi-variety parts processing problems.

Company Introduction

We specialize in the design and manufacture of CNC machine tools for decades.

There are following advantage:

1.Production capacity: with a area of over 40000 ㎡, 10 production lines.we produce 300 machines monthly.

2.Guaranteed production lead time: on stock available can be sent out within two weeks;

Regular production: within 45 days.

3.MOQ: Start from 1PC,depend on styles

3.Strong technical team: Rich experienced engineers with fame background work together to achieve any customize requirement.

4.After-sales service : Email, call, videos, even engineer visit available to assist any question during use.

5.Quality: We use servo motor and servo controller for our system from famous brands, such as Germany Rexroth,Fanuc,Taiwan Syntec etc.

There are following advantage:

1.Production capacity: with a area of over 40000 ㎡, 10 production lines.we produce 300 machines monthly.

2.Guaranteed production lead time: on stock available can be sent out within two weeks;

Regular production: within 45 days.

3.MOQ: Start from 1PC,depend on styles

3.Strong technical team: Rich experienced engineers with fame background work together to achieve any customize requirement.

4.After-sales service : Email, call, videos, even engineer visit available to assist any question during use.

5.Quality: We use servo motor and servo controller for our system from famous brands, such as Germany Rexroth,Fanuc,Taiwan Syntec etc.

Exhibition

Certificate

1.Lead the industry with the best in price value.

2.Total 5 manufacturing factories in China. One of them in Ningbo city, for more than 40000㎡.

3.We have multiple intellectual property rights and patented technology for CNC machines.

4.We have abound business resources around the whole China.

5.Professional & highly efficient technology support and one-stop services for you.

Packing&Shipping

FAQ

1. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.

2.What CNC system do you use?

A: FANUC, SIEMENS, MISTSUBISHI, LNC,GSK,etc. It depends on your choice.

3.When is the delivery time?

A: Conventional Machines,We will delivery then within 30-45 working days after received your deposit,if some special machines will be some longer.we will give you the answer accordingly.

4. What is the package of the machines?

A: The machines standard packed by iron pallets with plastic films.

5.How can I choose the most suitable machines ?

A: Please let us know your machining demand or machine size ,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

6. What is your trade terms?

A : FOB, CFR,CIF or others terms are all acceptable.

8. What is the payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight.

A: MOQ is one set, and warranty is one year.

2.What CNC system do you use?

A: FANUC, SIEMENS, MISTSUBISHI, LNC,GSK,etc. It depends on your choice.

3.When is the delivery time?

A: Conventional Machines,We will delivery then within 30-45 working days after received your deposit,if some special machines will be some longer.we will give you the answer accordingly.

4. What is the package of the machines?

A: The machines standard packed by iron pallets with plastic films.

5.How can I choose the most suitable machines ?

A: Please let us know your machining demand or machine size ,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

6. What is your trade terms?

A : FOB, CFR,CIF or others terms are all acceptable.

8. What is the payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight.

Hot Searches