- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2021

-

Brand Name:

-

Tongfang

-

Dimension(L*W*H):

-

1000*900*1000mm

-

Weight (KG):

-

800

-

Applicable Industries:

-

Machining, Parts processing, Mold processing

-

The machining accuracy:

-

0.015mm

-

Dimension of working table:

-

300*400mm

-

Travel of working table:

-

200*250mm

-

Machined taper:

-

6°/80mm

-

Max LoadCarring Capacity:

-

80kg

-

Total weight:

-

800kg

-

Overall dimensions:

-

1000*900*1000mm

-

Maximum cutting speed:

-

≥120mm²/min

-

Fixed speed of electrode wire:

-

11m/s

-

Consumed power:

-

3KVA

Quick Details

-

Marketing Type:

-

New Product 2021

-

Core Components:

-

Lead screw, Guide rail, Stepper motor, Electric control system

-

Place of Origin:

-

Jiangsu, China

-

Year:

-

2021

-

Brand Name:

-

Tongfang

-

Dimension(L*W*H):

-

1000*900*1000mm

-

Weight (KG):

-

800

-

Applicable Industries:

-

Machining, Parts processing, Mold processing

-

The machining accuracy:

-

0.015mm

-

Dimension of working table:

-

300*400mm

-

Travel of working table:

-

200*250mm

-

Machined taper:

-

6°/80mm

-

Max LoadCarring Capacity:

-

80kg

-

Total weight:

-

800kg

-

Overall dimensions:

-

1000*900*1000mm

-

Maximum cutting speed:

-

≥120mm²/min

-

Fixed speed of electrode wire:

-

11m/s

-

Consumed power:

-

3KVA

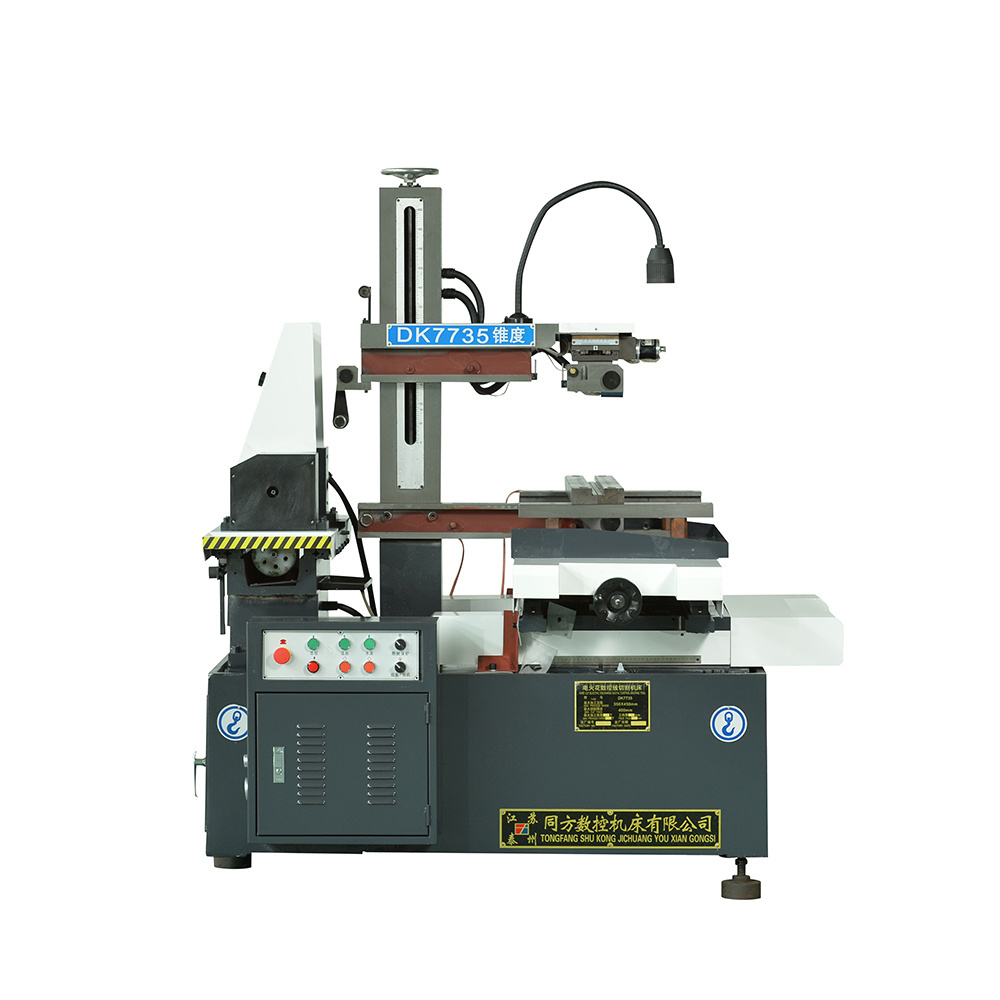

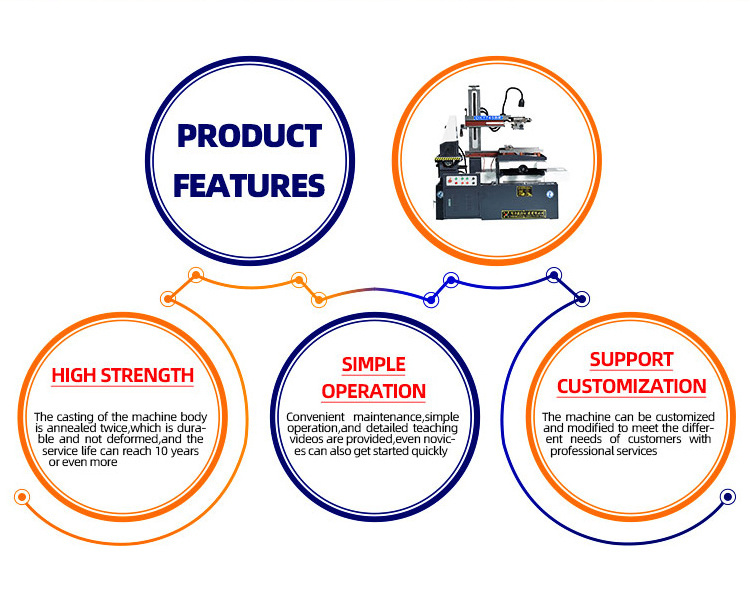

Taizhou Tongfang CNC has been focusing on the research and development of CNC wire cutting products for more than 20 years. The company produces a full range of DK77 CNC wire EDM machines, which use high-precision steel-inlaid V-shaped guide rails (linear guide rails are optional) and P3-level high-precision ball screws. The technology and quality have taken the lead in the industry among similar products, with complete models, long service life and high precision. Machine specifications can be customized according to customer needs, non-standard models DK7740(45)J, DK7750(55)J, DK7763J, DK7780J, DK77100J, DK77120J and even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision medium-speed wire EDM machines (accuracy≤±0.0025mm, roughness≤0.8μm). The following are the main parameters of DK77 series machines:

1. Standard maximum cutting taper: ±6°/80mm; (optional ±15°, ±30°, ±45°)

2. Accuracy ≤0.015mm, in line with GB7926-2005 standard; (if equipped with linear guide rail, the accuracy can reach 0.01mm)

3. The best surface roughness is less than or equal to Ra2.5μm (single knife), Ra1.5μm (multiple knife);

4. Molybdenum wire diameter: 0.1-0.2mm;

5. Max. Cutting speed≥120mm²/min;

6. Voltage: three-phase 380V (single-phase 220V, three-phase 220V or other voltages can be customized), power: 3KW;

7. Working fluid: water-based emulsion (recommended DX-1 DX-4 Nanguang-1)

|

Model number

|

DK7720

|

|

Dimension of working table

|

300*400mm

|

|

Travel of working table

|

200*250mm

|

|

Maximum cutting thickness of straight line

|

200mm

|

|

Machined taper

|

6°/80mm

|

|

Max LoadCarring Capacity

|

80kg

|

|

Total weight

|

800kg

|

|

Overall dimensions

|

1000*900*1000mm

|

|

Maximum cutting speed

|

≥120mm²/min

|

|

Optimum machining surface roughness

|

R≤2.5μm

|

|

Wire diameter

|

φ0.10-0.2mm

|

|

Fixed speed of electrode wire

|

11m/s

|

|

Working liquid

|

DX-1 DX-4 南光-1

|

|

The machining accuracy

|

0.015mm

|

|

Table movement pulse equivalent

|

0.001mm

|

|

Power supply machine tool

|

50Hz,380V(50Hz,220V)

|

|

Consumed power

|

3KVA

|

|

Model

|

Worktable travel(mm)

|

Worktable size (mm)

|

Max. cutting thickness(mm)

|

Max. load(kg)

|

Dimensions(mm)

|

Weight(kg)

|

|

DK7720

|

200*250

|

300*400

|

200

|

80

|

1000*900*1000

|

800

|

|

DK7725

|

200*320

|

320*510

|

300

|

120

|

1120*950*1240

|

1000

|

|

DK7735

|

350*450

|

360*630

|

400

|

300

|

1240*1170*1400

|

1200

|

|

DK7745

|

450*550

|

460*690

|

400

|

450

|

1600*1200*1400

|

1400

|

|

DK7755(50)

|

550*630

|

550*900

|

600

|

700

|

1720*1680*1700

|

2000

|

|

DK7763

|

630*800

|

650*1040

|

600

|

1000

|

2100*1940*1780

|

2500

|

|

DK7745J

|

450*630

|

460*840

|

400

|

500

|

1700*1600*1600

|

1800

|

|

DK7755J

|

550*800

|

550*1040

|

600

|

750

|

2000*1900*1700

|

2300

|

|

DK7763J

|

630*1000

|

650*1240

|

600

|

1100

|

2300*2200*1800

|

3000

|

|

DK7780

|

800*1000

|

890*1220

|

600

|

1200

|

3000*2400*1800

|

3500

|

|

DK7780J

|

800*1200

|

890*1560

|

600

|

1500

|

3000*2400*1800

|

4500

|

|

DK77100

|

1000*1200

|

1060*1590

|

600

|

2000

|

3500*2800*2500

|

5500

|

|

DK77100J

|

1000*1400

|

1060*1790

|

600

|

2200

|

3500*2800*2500

|

6000

|

|

DK77120J

|

1200*1600

|

1230*1880

|

600

|

3200

|

3800*3000*2500

|

8000

|

·Customers can choose one of the systems according to their needs;

·Because the X8 system is simple to operate and easy to maintain,the factory recommends X8 system,and the single-cut controller is equippedwith X8 by default

·The parameter adjustment reference table provides convenience for the operator to set the processing parameters

·Concise high-frequency parameter adjustment panel(Marked with English description)

·Adopt touch dustproof button

·Integration of programming and control; simultaneous programming of processing, real-time tracking and display of processing trajectory; three-dimensional modeling

·CAD/CAM data exchange operation for up and down special-shaped, equal radius, right-angle transition taper machining

·International standard ISO code control

·Fully enclosed, dust-proof and dirt-proof

·The parameter adjustment reference table provides convenience for the operator to set the processing parameters

·Concise high-frequency parameter adjustment panel(Marked with English description)

·Adopt touch dustproof button

·Integration of programming and control; simultaneous programming of processing, real-time tracking and display of processing trajectory; three-dimensional modeling

·CAD/CAM data exchange operation for up and down special-shaped, equal radius, right-angle transition taper machining

·International standard ISO code control

·Fully enclosed, dust-proof and dirt-proof

·With cutting speed adaptive control

·The cutting process is displayed in real time, and the processing preview is convenient

·Real-time monitoring of the machining status of the X, Y, U, V four axes of the machine tool

·With a user-maintainable process library, making multiple runs simple and reliable

Jiangsu Taizhou Tongfang CNC Machine Tool Co., Ltd.

is a high-tech enterprise integrating production, scientific research, sales and service. We have two production bases with a construction area of 36,000 square meters. we have been focusing on the research and development of CNC wire cutting products, and our technology and quality are at the forefront of the industry for 20 years. Our products also include middle speed wire cutting, high speed wire edm DK77 series, drilling machine, CNC spark machine.Stable quality, reliable performance and advanced technology make us a benchmark in the industry. Tongfang has won the trust of domestic and foreign customers with its high-quality service and good reputation. We look forward to becoming your most trusted partner.

Q:Are you manufacturer or distributor?

A:We are manufacturer,welcome to video call us via wechat or Facetime to visit our factory

Q2:How to choose the machine I want?

A:Firstly,please correspond to the worktable travel and cutting thickness according to the size of the workpiece to find a suitable model;

Secondly,please check if precision and roughness meet your requirements;(Our TF series middle speed wire cutting machines have much higher precision and better finish).

Q:Our country’s voltage is three-phase 220V(or single phase 220V,or other voltage), machine's voltage is three-phase 380V, can you change the voltage?

A:Yes, we will change it by what kind of voltage you need.

Q:Why choose you?What is the difference between you and other Chinese factory?

A: We have been focusing on the research and development of CNC wire cutting products over 30 years. We have two factories in Taizhou and the construction area over 50,000 square meters. Stable quality, reliable performance and advanced technology make us a benchmark in the industry. At the same time, we are also the supplier of many trading companies.

If any problems,we will provide you with solutions quickly by shooting videos or other ways.

Hot Searches