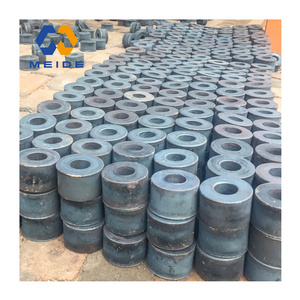

- Product Details

- {{item.text}}

Quick Details

-

OEM&ODM:

-

Yes

-

Module:

-

1mm-50mm

-

Accuracy:

-

DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0

-

Standard:

-

ISO/GB,JIS,AGMA,DIN

-

Application:

-

wind turbine, locomotive, metallurgy machinery, mining machinery

-

Gear shaft length:

-

2500mm max

Quick Details

-

Pressure Angle:

-

20 degree

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

NYY

-

OEM&ODM:

-

Yes

-

Module:

-

1mm-50mm

-

Accuracy:

-

DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0

-

Standard:

-

ISO/GB,JIS,AGMA,DIN

-

Application:

-

wind turbine, locomotive, metallurgy machinery, mining machinery

-

Gear shaft length:

-

2500mm max

Key Specification/Special Features

- In house capacity :generally machined according to customer's drawings

- Hardness treatments : annealing, normalizing, tempering, nitriding, carburizing and hardening and more

- Equipment : CNC machines, lathe machines, CNC milling machines, hobbling machines, grinding machines

- Engineering services : R&D process, tooling

- Surface : as per your requirements

Primary Competitive Advantages

- Experienced Manufacturer

- Competitive Price

- Prompt Delivery

- Long Lifespan

- Perfect Service

- Small Orders Accepted

- OEM orders are welcome

- Strong Technical Team

- World Advanced Production Equipment

| Tooth Profile: |

involute |

|---|---|

| Material: | 42CrMoA |

| Process: |

forging+tooth grinding+nitriding

|

| Grade |

AGMA 11

|

| Pressure Angle: | 20° |

| Model |

Mn=7,Z=68,a=20°;

|

| Original Place | wuxi,Jiangsu |

| Brand | NYY |

Jiangsu New Yinye Transmission Electromechanical Co.,Ltd is a high-tech enterprise specializing in manufacturing high

precision involute cylindrical gears,spur gear,dis-shaped helical gears,gear shafts,timing belt pulleys,gear boxes

.our productions have been applied in many industrial fields, such as wind power,

locomotive, marine, mining, agriculture,petrol facility and food machinery, etc.

Gear Production Capalicities

| Material: | Alloy steel | Casting steel | Gray cast iron | Ductile Iron | Weldment |

|---|---|---|---|---|---|

| 20CrMnTi | 20CrMnTi | HT200 | QT400-18 | 20CrMnTi | |

| 20CrMnMo | 20CrMnMo | HT250 | QT400-15 | 20CrMnMo | |

| 20 CrMo | 20 CrMo | 20 CrMo | |||

| 35CrMo | 35CrMo | 35CrMo | |||

| 42CrMo | 42CrMo | 42CrMo | |||

| 42CrMo | 42CrMo | 42CrMo | |||

| 20Cr2Ni4A | 20Cr2Ni4A | 20Cr2Ni4A | |||

| 20CrNiMo | 20CrNiMo | 20CrNiMo | |||

| 20CrNi2Mo | 20CrNi2Mo | 20CrNi2Mo | |||

| 40CrNiMo | 40CrNiMo | 40CrNiMo | |||

| 18CrNiMo7-6 | 18CrNiMo7-6 | 18CrNiMo7-6 | |||

|

17CrNiMo6 |

17CrNiMo6 | 17CrNiMo6 | |||

| 34 CrNiMo6 | 34 CrNiMo6 | 34 CrNiMo6 | |||

| 18Cr2Ni4WA | 18Cr2Ni4WA | 18Cr2Ni4WA | |||

| 18Cr2Ni4WE | 18Cr2Ni4WE | 18Cr2Ni4WE | |||

| 45 C | 45 C | 45 C | |||

| 40Cr | 40Cr | 40Cr | |||

| 38CrMoAl | 38CrMoAl | 38CrMoAl | |||

| 16Mn | 16Mn | 16Mn | |||

| 16MnCr5 | 16MnCr5 | 16MnCr5 | |||

| GCr15 | GCr15 | GCr15 | |||

| Module | 1mm-50mm | ||||

| Accuracy | DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0 | ||||

| Standard | DIN, ISO/GB, AGMA, JIS | ||||

| Heat treatment | Quenching and tempering, gear teeth induction quenching,nitriding,carburization | ||||

| Application |

Wind turbine, locomotive, feeding machinery, metallurgy machinery, mining machinery |

||||

| Gear shaft length | 2500mm max. | ||||

| Weight | 15 tons max. | ||||

Production Process

Professional production team, production line, experienced technical experts who engaged in this industry for

more than 10 years. We have the professional production line for gears:

1

.

High speed milling machines

2.

internal and external grinding machine

3. advanced equippment for producing gears

4 .all kinds of machining center,NC lathing machine,shaper,hobbing machine

Inspection Process

NYY quality control emphasis on APQP planning stage,pre strict quality recognition,make QCP quality plan make

preventive measures for quality issues that may occurred and focus tracking in the implementation process.focus

on the details of the quality process control.to ensure that meet or exceed customers quality requirements.

R&D Ability

our company owns more than 50 patents.our company has introduced several advanced engineering design

software and applied more than 30 new technologies and new processes. also,our company is certified by

ISO9001:2008 and ISO14001:2004.

1.suitable profile and lead modification makes meshing more perfect!

2 .professional modeling analysis softward,dynamic simulation technology can reduce the prophase test

processes,make the design more practical

Please send me your drawings if you are interested in our products,thanks!