- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

10300*4500*2100mm

-

Weight:

-

17500

-

Power (kW):

-

7.5

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Huadeyu

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

10300*4500*2100mm

-

Weight:

-

17500

-

Power (kW):

-

7.5

Application

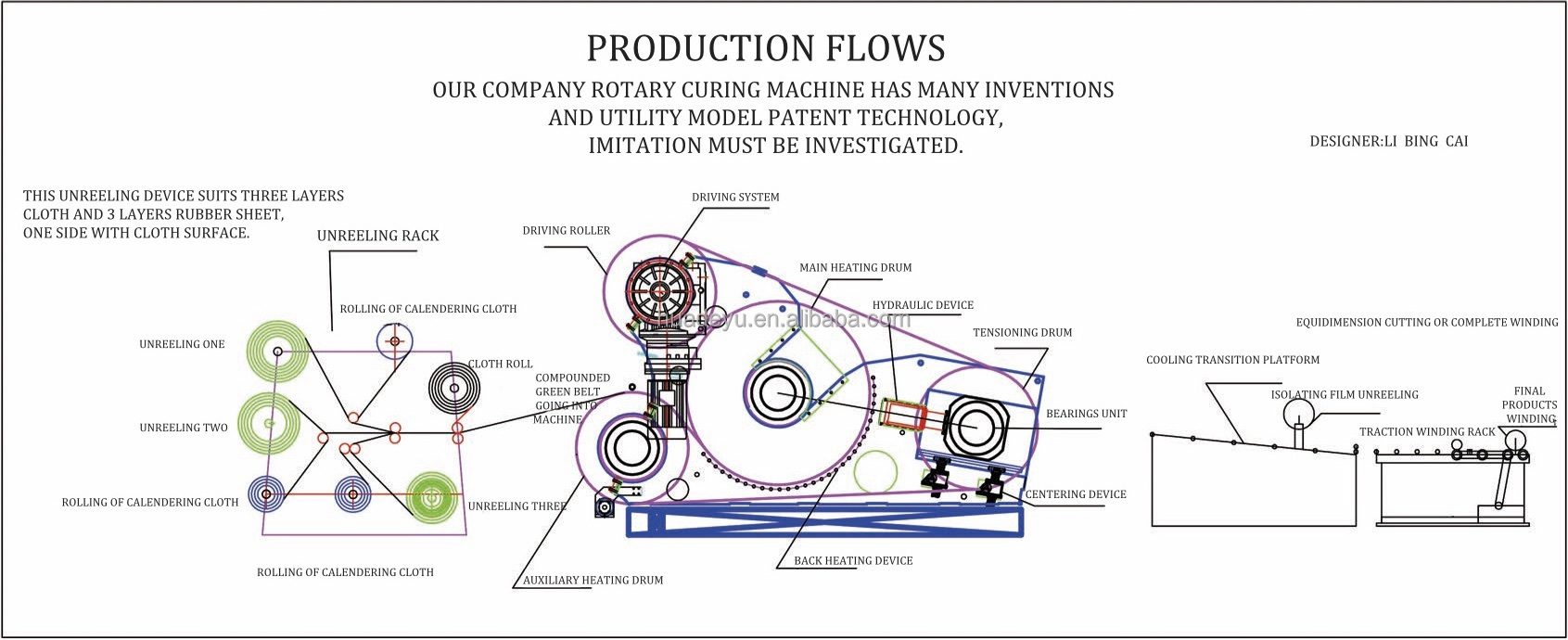

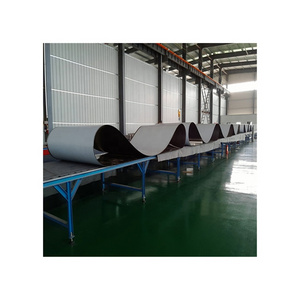

It is mainly used in vulcanizing various kinds of rubber plates, conveyor belt, embossed film,waterproof material, printing mackintosh, products.

Configurations and technical parameters:

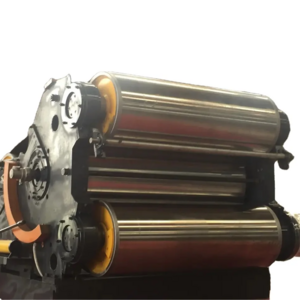

1.Main drum diameter 1500mm, width 1450mm,oil heating,mirror smooth drum. Vulcanizing temperature : room temperature - 220 ℃. The pattern drum diameter 1500mm,width 1450mm, being used with the main machine, anti-rust treatment on the surface.

2.The auxiliary roller and the driving roller diameter 800mm, width 1450mm,wall thickness 45mm,the surface is plated with hard chrome,hardness layer thickness 0.03mm,the auxiliary roller is steam heating; the tensioning roller diameter 1000mm.

3. The oil cylinder diameter 180mm,stroke 300mm,build-in structure, the maximum tensioning pressure 120T.

4. Bearings adopts HRB bearings, double rows high-temperature resistant needle roller bearings, inner diameter 280mm,outer diameter 420mm, thickness 140mm.

5. The driving system adopts swing needle wheel, inverter motor(range 0-50HZ,Shanghai made),power 7.5KW, curing liner speed 0-5 meters / minute.

6. Single wall frame width 160mm (double walls frame structure, whole steel plate cutting, welding structure),single plate thickness 20mm.

7. The base is welded by 200# channel steel ,refreation treatment after overall processing.

8. The pressure system adopts automatic aftercompaction decompression function, adopting digital pressure gauge, the pressure range 0-25MPA.

9. The electrical cabinet (self-made), low pressure electrics adopts “CHINT”,the press button and switch adopts “ SCHNEIDER”,the drive adopts “SIFANG”.

10. Steel belt run-away infrared alarm device.

11. The steel belt centering device adopts manual electric integration device,20T lift structure.

12. Back heating device (electrical heating tubes structure)

13. Steel belt and main drum cleaning device.