Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WEIER

-

Voltage:

-

380v,3p,50HZ

-

Dimension(L*W*H):

-

22*1.5*2.6 (m)

-

Power (kW):

-

120

-

Weight:

-

12 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

wpc machine type:

-

wpc pallet production line

-

wpc extrusion line speed:

-

0.5-1.5m/min wpc pallet production line

-

wpc products application:

-

ceiling, floor, skirting, railing, door, window, pillar, fence

-

wpc extrusion line capacity:

-

250kg/h max. wpc pallet production line

-

material of screw:

-

38CrMoAIA

-

mold of wood plastic extruder:

-

as per customers' wpc post production line

-

motor power:

-

37kw wood plastic composite production line

-

temperature controller:

-

omron

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

80 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WEIER

-

Voltage:

-

380v,3p,50HZ

-

Dimension(L*W*H):

-

22*1.5*2.6 (m)

-

Power (kW):

-

120

-

Weight:

-

12 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

wpc machine type:

-

wpc pallet production line

-

wpc extrusion line speed:

-

0.5-1.5m/min wpc pallet production line

-

wpc products application:

-

ceiling, floor, skirting, railing, door, window, pillar, fence

-

wpc extrusion line capacity:

-

250kg/h max. wpc pallet production line

-

material of screw:

-

38CrMoAIA

-

mold of wood plastic extruder:

-

as per customers' wpc post production line

-

motor power:

-

37kw wood plastic composite production line

-

temperature controller:

-

omron

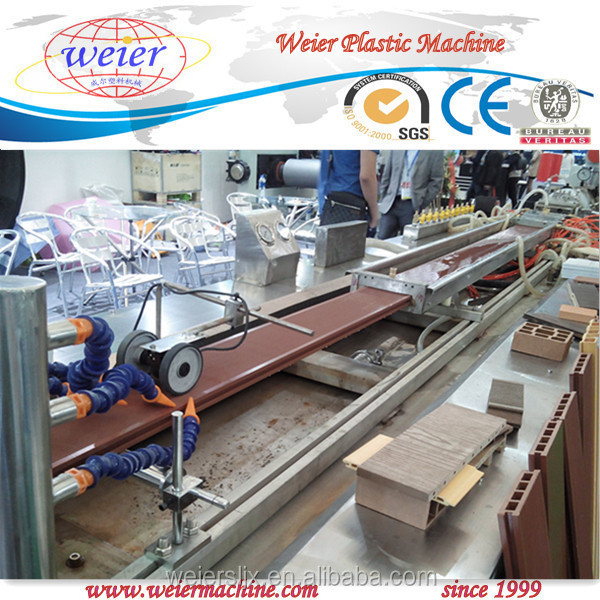

Wood Plastic Composite WPC Profiles Production Line ( CE, turn key project)

wpc decking hollow board extrusion line; production line for wood plastic decking profiles; wpc pvc siding production line; WPC deco profile extrusion machine; wpc floor terrace board extrusion line

1. Application of wood plastic composite wpc profiles- plastic wood composite board extrusion machine

our wpc wood plastic composite profile extrusion machine, compounding domestic and abroad technology, with characters of high automatic level, steady performance, large output and high efficiency. it is most professional for producing various kinds of wpc profiles both outdoor and indoor by changing different moulds---- that means in same extrusion machine line, you can produce different wpc profiles by just changing different moulds!

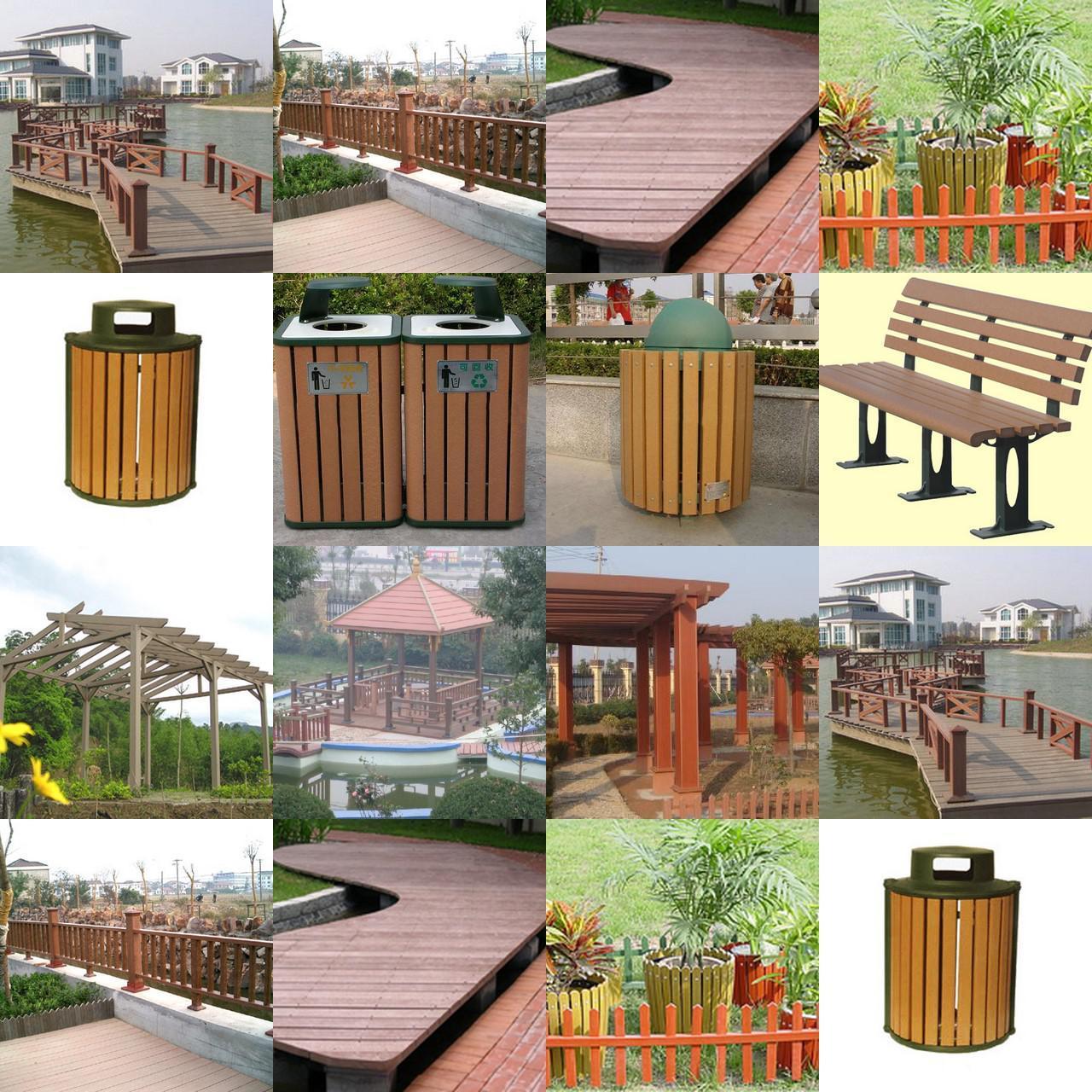

outdoor application: wpc hollow decking, wpc solid decking, WPC beam/joist/keel, wpc wall cladding panel, wpc bench/chair, wpc fence/railing, upright post/pillar, wpc pavilion, wpc roof profiles, etc

Indoor application: door window profiles, furniture decorative profiles, foaming profiles, etc

2. Production process for equipment for the production of wood plastic profiles- plastic wood composite board extrusion machine

1) for PP,PE WPC profiles extrusion craft:

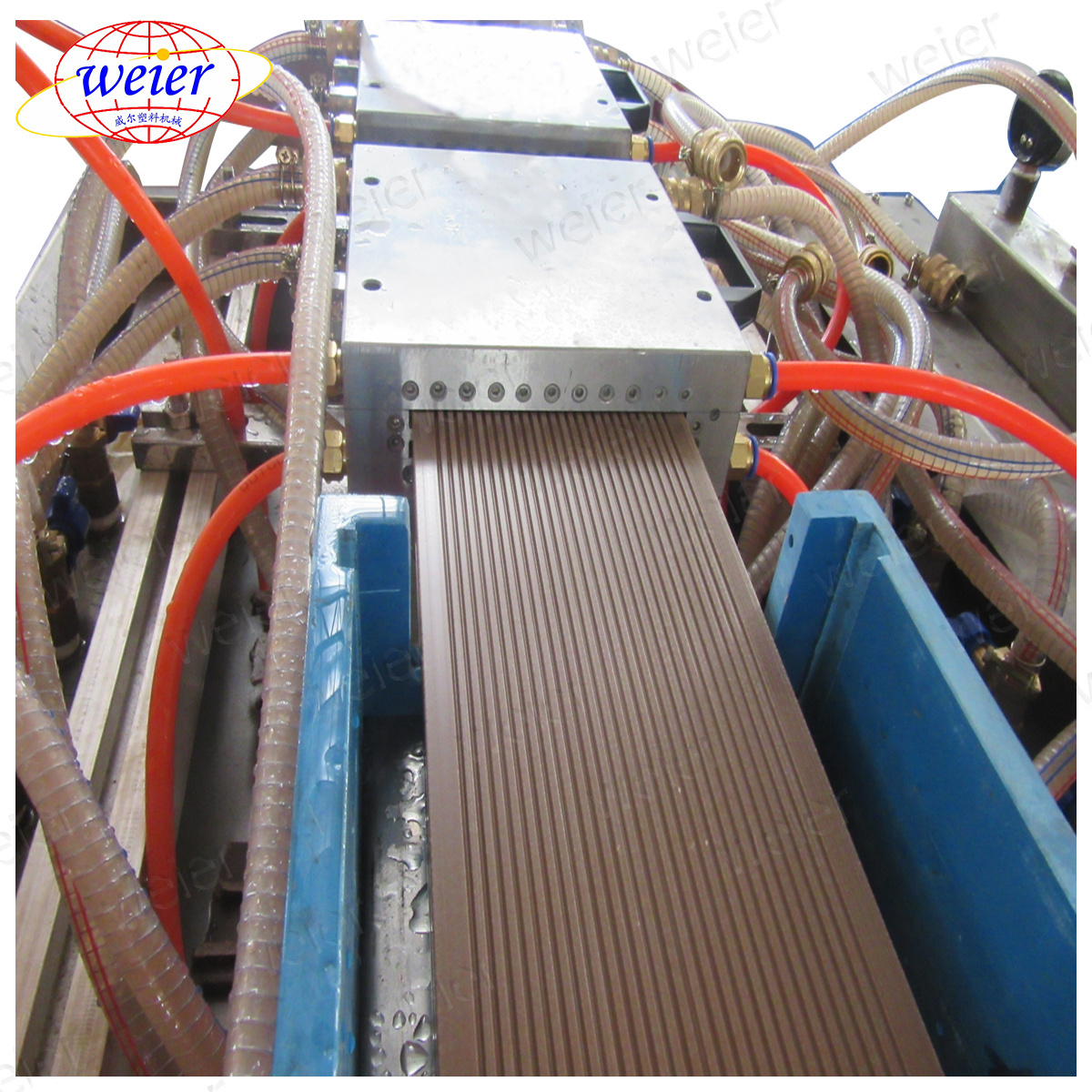

100% recycled PP,PE,etc+wood power ( from wood dust, rice husk, wheat straw,etc)+ additives → mixing → granulating → conical twin-screw extruder → profile extrusion die → profile moulds→ vacuum calibration platform →(haul-off) → cutter →stacker → finished product → surface finish processing, like embossing, sandng, brushing,etc

2) for PVC WPC profiles extrusion craft:

pvc powder+wood powder+additives → mixing → extrusion line ( conical twin-screw extruder → profile extrusion die → profile moulds→ vacuum calibration platform →haul-off → cutter →stacker → finished product) → surface finish processing ( like heat transfer,sanding, embossing,etc)

3. Equipment list for wpc profile machine, wood plastic wpc profiles extrusion line

PP PE PVC WPC Profiles Extrusion Line- wood plastic composite wpc profile manufacturing machine

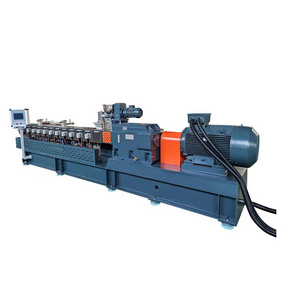

3.1 Twin Screw Extruder SJSZ-65/132

3.2 Extrusion die

3.3 Profile moulds

3.4 Vacuum Calibrating Table

3.5 haul-off machine

3.6 Cutting machine

3.7 Tilting table

3.8 Electrical control cabinet

4. Machine List for WPC Production Line

| name & link | model | photo | details |

| wood powder production line | 350-400kg/h,etc different capacity models for choice |

|

crushing-drying-pulverizing-screening to get wood powder 80-120meshes suitable for wpc

(raw material: wood sawdust, wood shavings, wood chips, rice husk, wheat straw,etc) |

| high speed cooling mixer |

SHRL-300/600, SHRL-500/1000 / SHR-20, SHR-500 for choice |

|

mixing raw materials as per formulation |

|

(pls click the link to find more details of PE wpc granulation) |

250kg/h; 350-400kg/h for choice | to make PP/PE WPC compound granules, by parallel twin screw extruder | |

|

PP,PE,PVC WPC wood plastic profile extrusion line (pls click the link, to check more details pf wpc profile production line) |

WRSJ-51/105 (120-150kg/h); WRSJ-65/132 (180-250kg/h); WRSJ-80/156 (300-350kg/h); WRSJ-92/188 (600kg/h) of single,double,multi-output design |

|

process pvc/pp/pe wood plastic/ polymer composite wpc profiles-outdoor & indoor, such as decking, flooring, wall panel, siding, railing, fence,post,pavillion,decking keel,joist,chair,bench,round&square pipe for decoration, slat, roofing profile,etc

WE HAVE CHINA NO.1 BIGGEST WPC PRODUCTION CENTER RUNNING, WITH PRODUCTION 23 LINES, FOR YOUR VISIT!

|

|

WPC product samples-WPC based on PVC,WPC based on PP/PE

(smooth,curved, embossed,sanding, brushing, etc) |

|

|

by changing molds, can produce different kinds of wpc products! |

|

(pls click the link to find more details) |

630-1300 | ||

|

( pls click the link to find more details) |

400-1300 ( different wood grain texture patterns for choice) | ||

|

PVC WPC hollow door board production line

( pls click the link and check more details for wpc door machine) |

WRSJ-92/188 |

|

width=700mm, 800mm, 900mm,etc 600kg/h capacity |

|

PVC WPC CELUKA foam board manufacturing machine

(pls check the link and find more details of wpc pvc celuka foam board machinery) |

SJSZ-80/156; SJSZ-92/188 |

width=1220mm,etc thickness=5-20mm, 5-25mm, 6-30mm,etc |

|

|

Ecological Lesco Greener wood PVC WPC profile extrusion line

(pls click the link and find more details of lesco pvc wpc profile machine) |

SJ-65/25, SJ-75/25, SJ-90/25 | first to make granules from pvc powder, wood powder and color pigment, additives;then extrusion from single screw extruder to make wpc ecological profiles with natural wood grain texture |

WPC wood plastic profiles extrusion line