- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HongXing Brand

-

Dimension(L*W*H):

-

Different

-

Weight:

-

13000 KG

-

Product name:

-

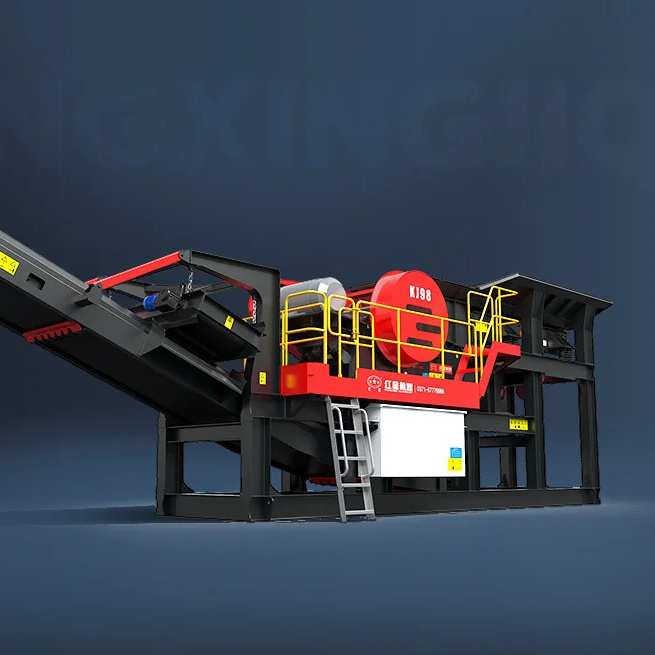

Mobile Stone Crusher

-

Keyword:

-

Fine Stone Crusher

-

Color:

-

Customer Requirement

-

Applicaton:

-

Stone Process

-

Advantage:

-

High Efficiency Low Energy

-

After sale Service:

-

1 Year Warrenty

-

Price:

-

Negotiatable

-

Certification:

-

ISO9001:2008

-

Factory visit:

-

Warmly Welcomed

-

Function:

-

Mining Crusher Equipment

Quick Details

-

Application:

-

mining,ore

-

Capacity(t/h):

-

85-200t/h

-

Place of Origin:

-

Henan China(Mainland)

-

Brand Name:

-

HongXing Brand

-

Dimension(L*W*H):

-

Different

-

Weight:

-

13000 KG

-

Product name:

-

Mobile Stone Crusher

-

Keyword:

-

Fine Stone Crusher

-

Color:

-

Customer Requirement

-

Applicaton:

-

Stone Process

-

Advantage:

-

High Efficiency Low Energy

-

After sale Service:

-

1 Year Warrenty

-

Price:

-

Negotiatable

-

Certification:

-

ISO9001:2008

-

Factory visit:

-

Warmly Welcomed

-

Function:

-

Mining Crusher Equipment

The MTN series of wheel-type mobile production lines fully cover the application fields of hard rock, soft rock,and construction waste with a processing capacity of 100-300 tons per hour.

The overall appearance of the mobile station is beautiful,the workmanship is exquisite, the host is equipped with the latest technology, the performance is stable and reliable, and the output is high. A large number of belt conveyors which are assembled on the trailer eliminate the need for on-site transfer and external belt conveyors, and the work site is tidy and organized; Each mobile station is equipped with a crawler plate device to ensure that the equipment arrives at the site quickly for installation and commissioning, and reduces the concrete foundation preparation time.

Equipment Advantage

High-Performance Main Machine

The main equipment on the production line are all high- performance machines produced with the latest industry technology, with high efficiency,high output, few failures, convenient operation and maintenance,and stable and reliable operation.

Modular Design

The MTN series mobile production line adopts modular and universal design, with high structural strength and strong

versatility. The equipment with the same processing capacity can achieve maximum versatility.

Humanized Maintenance Platform

The front and back connection design of the maintenance platform is convenient for the operator to observe the

equipment operation in time and maintain it.Inclined up and down escalators, wider pedals, safer and more convenient

than upright ladders. Some models add a small climbing ladder at the rear, which is convenient for personnel to check and maintain.

Trailer-Mounted Electronic Control System

Each device of the mobile production line is equipped with an independent electronic control system,which is easy to operate. The cables of each device have been connected

before leaving the factory. There is no need to disassemble for transportation. The whole machine can be debugged quickly when it arrives on site.

Trailer-Mounted Belt Conveyor

Each equipment of the mobile production line is equipped with a vehicle mounted belt conveyor, which does not need to be disassembled during transportation and it saves the time for on-site production and installation of external belt conveyors. Work can be started quickly when arriving at the site, and the work site is clean and orderly.

Concrete Foundation Free

Each equipment of the mobile production line is equipped with an outrigger crawler device, which can save the cost and time of the concrete foundation, reduce the requirements for the foundation of the work site,and reduce the foundation investment.It is put away during

transportation and transfer, and can be quickly supported when arriving at the site.

Large Volume Silo Design

Both the feeder silo of the coarse crushing equipment and the feeding belt conveyor silo of the medium crushing equipment adopt a large capacity design. Certain materials can be stored to ensure uniform and stable feeding.The large capacity silo is convenient for fee ding and can store certain materials at the same time to ensure uniform and stable feeding.

Precisely Control the Feeding Amount

The feeder adopts frequency o conversion control, and the feeding amount of the feeder can be adjusted according to different conditions to give full play to the production capacity of the production line.The feeder is equipped with a pre- screening function, which can separate finely divided materials and muck in advance and imp rove the processing capacity of the equipment.

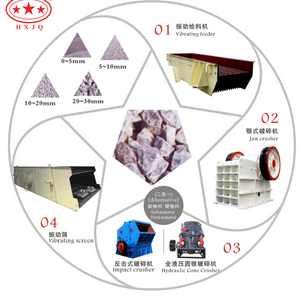

Application fields: Wotetrack cone crusher station is widely applied in metallurgical, construction, road building, chemical and phosphatic industry.

Working Principle

Material by the feeder evenly to the jaw crusher, after beginning of jaw crusher broken material by the conveyor into the counterattack crusher for secondary crushing, crushing the material through the sieve sieve, satisfies the requirement of the broken material from the conveyor output, does not meet the requirements of the material into the counterattack crusher broken again, the caterpillar jaw crusher + reaction type mobile crushing plant production line through circular vibrating screen constitute closed-circuit system, realize the material cycle of broken, finished product material from the conveyor output, continuous crushing operations.

Technical Parameter

|

Series

|

Standard Model

|

On Board Equipment

|

On Board Equipment

|

Processing Capacity(t/h)

|

Transport Dimensions(mm)

|

|

Four Combination Mobile Station

|

MTN100Y-2

|

GZD850*3000/2YK1545

|

HD72/GYS300

|

50-100

|

15000*2650*4500

|

|

|

MTN100Y-3

|

GZDT0835/3HX1548

|

HDX86/SC100F1

|

50-100

|

17500*2500*4000

|

|

|

MTN150Y-3

|

GZDT0835/3HX1548

|

HDX86/SC160F1

|

70-150

|

17500*2500*4000

|

|

|

MTN-150R-3

|

GZDT0835/3HX1548

|

HDX86/CI1110

|

60-150

|

17500*2500*4000

|

|

Mobile Coarse Crushing Station

|

MTN96

|

GZDT9538

|

CJ96

|

70-200

|

13000*2950*4250

|

|

|

MTN98

|

GZDT9538

|

HDX98

|

80-200

|

13000*2950*4250

|

|

|

MTN106

|

GZDT1145A

|

CJ106

|

90-300

|

14000*3000*4400

|

|

|

MTN110

|

GZDT1145A

|

HDX110

|

120-300

|

14000*3000*4400

|

|

|

MTN1213C

|

GZDT9538

|

CI1213

|

80-200

|

13000*2950*4250

|

|

|

MTN1316C

|

GZDT1145A

|

CI1316

|

100-300

|

14000*3000*4400

|

|

Mobile Medium and Fine Crushing Station

|

MTN300

|

---

|

HPM300C1

|

100-200

|

15500*2900*4200

|

|

|

MTN400

|

---

|

HPM400C3

|

150-300

|

16500*3100*4300

|

|

|

MTN250

|

---

|

SC250F1

|

90-200

|

16500*3100*4300

|

|

|

MTN1213

|

---

|

CI1213

|

80-200

|

16000*2900*4300

|

|

|

MTN1316

|

---

|

CI1316

|

100-300

|

16500*3100*4500

|

|

|

MTN0926

|

---

|

HVI0926

|

85-200

|

16500*3100*4300

|

|

|

MTN1040

|

---

|

HVI1040

|

120-300

|

16500*3100*4400

|

|

Mobile Screening Station

|

MTN1865-3

|

---

|

3HX1865

|

65-200

|

14500*2900*4000

|

|

|

MTN2165-3

|

---

|

3HX2165

|

85-300

|

15000*2900*4400

|

|

Mobile Station For Medium and Fine Crushing and Screening

|

MTN300S-3SII

|

3HX1865

|

HPM300C1

|

100-200

|

15000*3000*4000

|

|

|

MTN300S-3

|

3HX2165

|

HPM300C1

|

100-200

|

15000*3000*4000

|

|

|

MTN400S-3

|

3HX2165

|

HPM400C3

|

150-300

|

15000*3000*4000

|

|

|

MTNG400S-3SII

|

3HX1865

|

GYS400C1

|

100-200

|

15000*3000*4000

|

|

|

MTN400S-3

|

3HX2165

|

GYS400C1

|

100-200

|

15000*3000*4000

|

|

|

MTN250S-3

|

3HX2165

|

SC250F1

|

90-200

|

15000*3000*4000

|

|

|

MTN1213S-3

|

3HX1865

|

CI1213

|

80-200

|

15000*3000*4200

|

|

|

MTN1316S-3

|

3HX2165

|

CI1316

|

100-300

|

15000*3000*4200

|

|

|

MTN0926S-2

|

3HX1865

|

HVI0926

|

85-200

|

18000*3000*4200

|

|

|

MTN1040S-2

|

3HX2165

|

HVI1040

|

120-300

|

18000*3000*4200

|

|

Three Combination Mobile Station

|

MTN1213-III

|

GZDT9538/3HX1865

|

CI1213

|

80-200

|

18200*2800*4350

|

|

|

MTN1316-III

|

GZDT1145A/3HX1865

|

CI1316

|

100-300

|

18200*3000*4200

|

|

|

MTN1410-III

|

GZDT9538/3HX1865

|

PCZ1410

|

80-200

|

18200*2800*4200

|

|

|

MTN1612-III

|

GZDT1145A/3HX2165

|

PCZ1612

|

100-300

|

18200*3000*4200

|

Mobile Jaw Crushing Station

Mobile Impact Crushing Station

Mobile Cone Crushing Station

Mobile Screening Station

About Us

Hongxing Group is a comprehensive large scale joint stock enterprise integrating scientific research, production, sales and after sales. Formerly known as the 55201 Machine Factory of the Chinese People's Liberation Army, it was a military enterprise and an important enterprise of "high-tech" scientific research and technology development in China at that time, with a strong technical background.The existing R&D,management, production and marketing staff of more than 2,300 people, four modern production bases covering an area of 350,000 square meters, is a national high tech enterprise and domestic high-e mining machine production and export base. The Group focuses on mining machine manufacturing, covering four series crushing sand making, screening and grinding, while providing customers with engineering design and EPC general contracting services, adhering to the "one enterprise, one policy" tailor-made ore processing solutions

Four major production bases

For more than 40 years, the Group has never forgotten t he original intention of creating a Chinese industrial brand and creating a world class mining machine, always adhering to the mission of creating greater value for customers, continuously improving scientific research investment in the development of new products, optimizing and upgrading project solutions, and making unremitting efforts to improve the production and operation income of customers. Products have passed ISO9001, CE (European Union), GOST (Russia) and other international quality system certification. Forever first-class Hongxing Machinery provides services to tens of thousands of mining enterprises around the world and has been universally praised.

Packing & Delivery

Ways of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Customer Photos and Company Honor

Why Choose Us?

We are manufacturer of stone crushers and grinding mills since 1995.Formerly known as the 55201 Machine Factory of the Chinese People's Liberation Army, it was a military enterprise and an important enterprise of "high-tech" scientific research and technology development in China at that time, with a strong technical background.

We follow the standard of CE, ISO9001, Ghost, CU-TR.

Our factory convers 350000㎡. Welcome to see machines.

We send engineers for installation, commissioning and training.

We have sufficient spare parts in stock.

Our products are sold all over the world

Fast maintenance system to deal with customers's after sales issue in time.

Hot Searches