●

Filling accuracy expectation of:

●

± 2% (for 0.5 ml to 5 ml fill volume)

●

± 1% (for 5ml to 15 ml fill volume)

●

± 0.5% (over 15 ml fill volume)

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥ 99.7%

-

Voltage:

-

110v/220v 3 phase

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Bottlinglife

-

Dimension(L*W*H):

-

2150x1450x2100

-

Weight:

-

450 KG

-

Product name:

-

Bottlinglife

-

Function:

-

Filling Capping Labeling

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Feature:

-

High Precision Filling Level

-

Processing Types:

-

Servo Motor Drive

-

Advantage:

-

PLC+English Panel Control

-

Filling Product:

-

Oil Liquid

-

Filling speed:

-

40 bottle/min

-

Package material:

-

Glass bottle

-

Filling Precision:

-

99%

Quick Details

-

Machinery Capacity:

-

4000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Wood, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder, jam, paste

-

Filling Accuracy:

-

≥ 99.7%

-

Voltage:

-

110v/220v 3 phase

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Bottlinglife

-

Dimension(L*W*H):

-

2150x1450x2100

-

Weight:

-

450 KG

-

Product name:

-

Bottlinglife

-

Function:

-

Filling Capping Labeling

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Feature:

-

High Precision Filling Level

-

Processing Types:

-

Servo Motor Drive

-

Advantage:

-

PLC+English Panel Control

-

Filling Product:

-

Oil Liquid

-

Filling speed:

-

40 bottle/min

-

Package material:

-

Glass bottle

-

Filling Precision:

-

99%

Product Paramenters

|

Description

|

Oil Liquid Filling Machine

|

|

Filling Nozzel

|

2

|

|

Capping Head

|

2

|

|

Filling Capacity

|

10ml-100ml

|

|

Filling Speed

|

30/bpm

|

|

Air Pressure

|

0.6Mpa

|

|

Volt

|

220V

|

|

Power

|

4kw

|

The Equipment intergrates Feeding-Filling -Capping-Labeling

Product Details

Filling accuracy expectation of

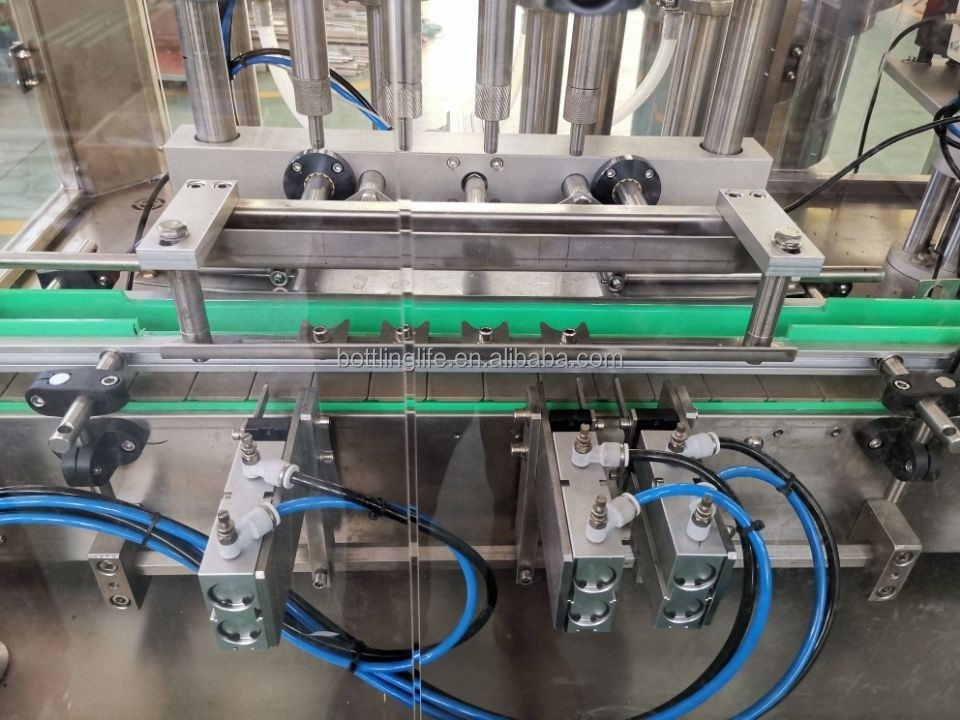

Filling Nozzle

●

Stainless steel 316L

● Spring loaded ball check valve

● With re-enforce silicon hoses (food Grade) for product transfer

● Custom attachment system for BottlingLife equipment

● Final design adapted to the product to be fill (To Be Confirm)

● Spring loaded ball check valve

● With re-enforce silicon hoses (food Grade) for product transfer

● Custom attachment system for BottlingLife equipment

● Final design adapted to the product to be fill (To Be Confirm)

Filling Nozzle with Shut Off System

●

Preventing dripping with viscous & semi viscous products

● Stainless steel 316L

● Pneumatic activated plunger for sealing the nozzle

● Quick disconnect air hose system for wash down

● Dismantling of the nozzle with the usage of any tools

● With re-enforce silicon hoses (food Grade) for product transfer

● Stainless steel 316L

● Pneumatic activated plunger for sealing the nozzle

● Quick disconnect air hose system for wash down

● Dismantling of the nozzle with the usage of any tools

● With re-enforce silicon hoses (food Grade) for product transfer

Volumetric Piston for Liquid Products

●

Ball check valve in stainless steel 316L

● Stainless steel 316L Volumetric chamber

● Pistons with autoclavable packing, GMP approved material

● “Tri Clamp” Attachment system

● Infeed Ø out feed Ø

● Dismantling of the complete piston without tool

● Servo motor control

● Stainless steel 316L Volumetric chamber

● Pistons with autoclavable packing, GMP approved material

● “Tri Clamp” Attachment system

● Infeed Ø out feed Ø

● Dismantling of the complete piston without tool

● Servo motor control

Capping Station (Screw Caps)

●

One (X 1) transfer star wheel for Capping station

● Tube Alignment with ‘’Funnel’’ Device to properly introduce the cap into the bottle

● One (X 1) final independent motor torque control

● Torque accuracy 0.2 Nm (± 2 in.-lb.) across a range of 0.56 to 22.4 Nm (5 – 100 in.-lb.)

● Maganetictorque adjustable tighten the cap to prevent any damage to the caps

● Torque adjustable in percentage directly form the HMI

● Tube Alignment with ‘’Funnel’’ Device to properly introduce the cap into the bottle

● One (X 1) final independent motor torque control

● Torque accuracy 0.2 Nm (± 2 in.-lb.) across a range of 0.56 to 22.4 Nm (5 – 100 in.-lb.)

● Maganetictorque adjustable tighten the cap to prevent any damage to the caps

● Torque adjustable in percentage directly form the HMI

Features

Euroguard Safety Interlock System

●

6 mm (¼’’) thick tempered glass barrier doors shield the machine perimeter

● Doors are mounted on stainless steel tubing which also enclosed the electrical wirings.

● Safety interlocks are installed to ensure the safety of the operators before

● Doors are mounted on stainless steel tubing which also enclosed the electrical wirings.

● Safety interlocks are installed to ensure the safety of the operators before

Structure

●

Frame in anodized aluminum completely covered in stainless steel 304 * Adjustable support legs for in-line positioning and

levelling. with ± 38 mm (1 ½ ‘’) adjustment capability

● Raised working surface for easy cleaning

● Machine as multiple brushless motors for a smooth and

flexible machine operation

● Electrical and mechanical part located inside the machine frame for a complete protection

● Top plate of the base completely sealed against liquid

● infiltration protecting all internal mechanical parts

levelling. with ± 38 mm (1 ½ ‘’) adjustment capability

● Raised working surface for easy cleaning

● Machine as multiple brushless motors for a smooth and

flexible machine operation

● Electrical and mechanical part located inside the machine frame for a complete protection

● Top plate of the base completely sealed against liquid

● infiltration protecting all internal mechanical parts

Control System

●

Stainless steel panel control

● Stainless steel, tubular holding post with Twin axis swivel panel control

● Emergency Stop on the control panel

● Machine controlled with industrial PLC

● (7’’) multi-color touch screen control• HMI resolution

● Programmable feeder, conveyor speed, etc.

● For normal machine operation with alarm display

● Possibility to have different language interfaces

● Stainless steel, tubular holding post with Twin axis swivel panel control

● Emergency Stop on the control panel

● Machine controlled with industrial PLC

● (7’’) multi-color touch screen control• HMI resolution

● Programmable feeder, conveyor speed, etc.

● For normal machine operation with alarm display

● Possibility to have different language interfaces

Recommend Products

Hot Searches