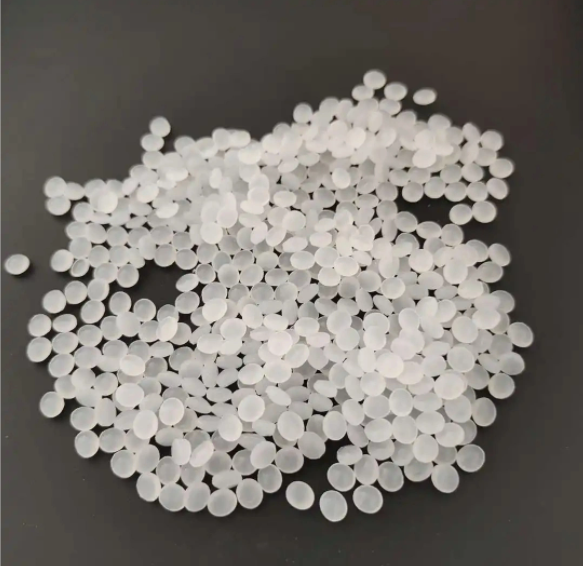

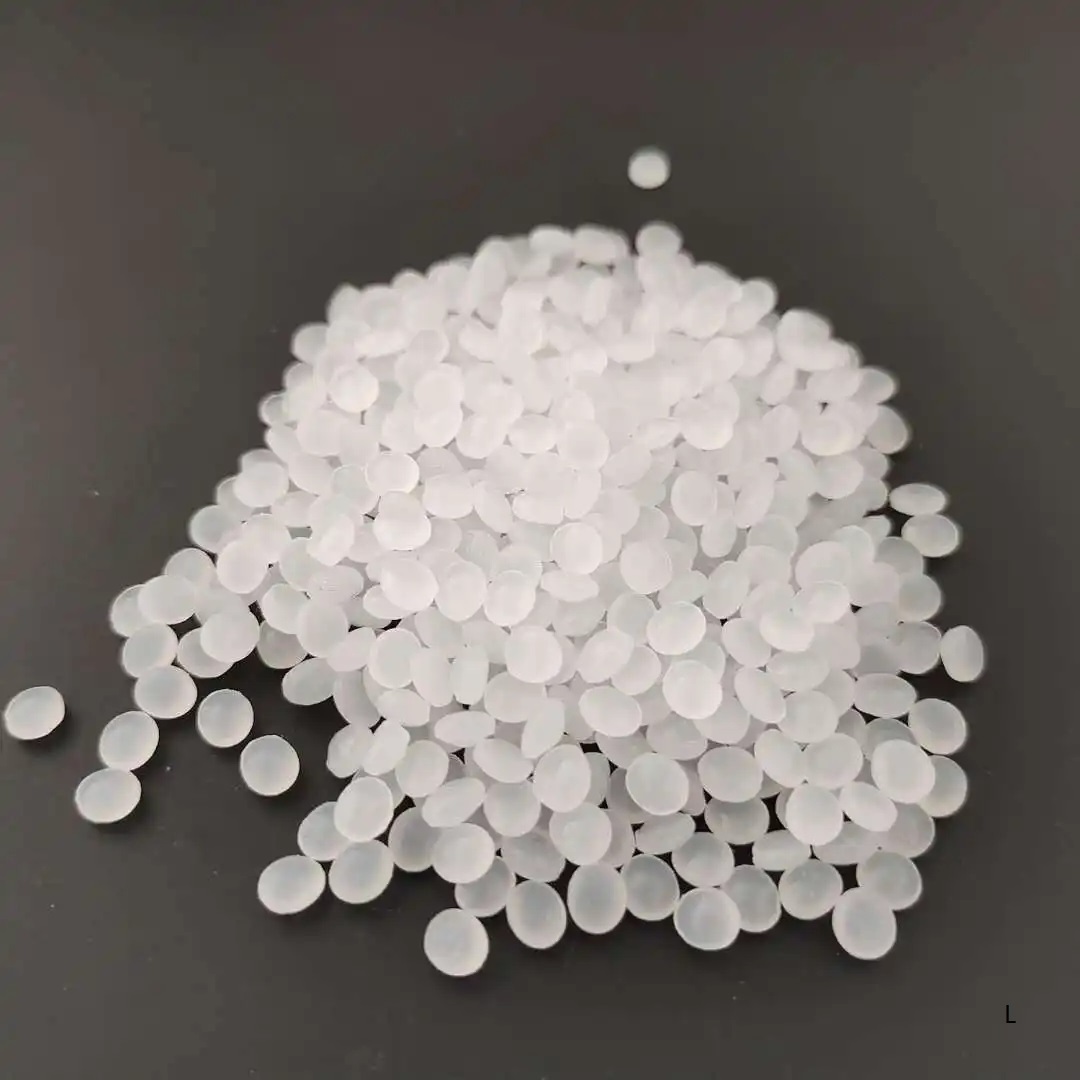

Low density polyethylene, also known as high pressure polyethylene (LDPE), is the lightest variety of polyethylene resin, is milky white, tasteless, odorless, non-toxic, the surface of the waxy particles. It has good flexibility, extensibility, electrical insulation, transparency, easy processing and certain air permeability. Its chemical stability is good, alkali resistance,

resistance to general organic solvents.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

suiliang

-

Model Number:

-

Virgin LDPE

-

Appearance:

-

Granule

Quick Details

-

color:

-

Opalescent

-

Shape:

-

granule

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

suiliang

-

Model Number:

-

Virgin LDPE

-

Appearance:

-

Granule

Product Description

Specification

|

item

|

value

|

|

Origin

|

China

|

|

HS Code

|

390319900

|

|

Brand Name

|

suiliang

|

|

Specification

|

0.35

|

|

Appearance

|

Granule

|

Product Paramenters

|

Item

|

Value

|

Unit

|

standard

|

|

Density

|

0.924

|

g/cm3

|

ISO 1183

|

|

Melt Index 190ºC

|

2.0

|

g/10min

|

ISO 1183

|

|

Hardness D

|

48

|

|

ISO 868

|

|

Tensile strength

|

10

|

Mpa

|

ISO 527

|

|

Tensile Modulus

|

270

|

Mpa

|

ISO 527

|

|

Elongation

|

800

|

|

ISO 527

|

|

Melting temperature

|

112

|

|

ISO 11357

|

Application

Low density polyethylene polymerization method, can be divided into high pressure and low pressure method. According to the

reactor type can be divided into kettle method and tube method. With ethylene as raw material, into the reactor, under the action

of initiator with high pressure compression polymerization reaction, from the reactor out of the material, by the separator to

remove the unreacted ethylene, after the melting extrusion granulation, drying, mixing, sent to packaging.

reactor type can be divided into kettle method and tube method. With ethylene as raw material, into the reactor, under the action

of initiator with high pressure compression polymerization reaction, from the reactor out of the material, by the separator to

remove the unreacted ethylene, after the melting extrusion granulation, drying, mixing, sent to packaging.

Hot Searches