- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5500*2750*2300mm

-

Power (kW):

-

18.7KW

-

Weight (KG):

-

380 kg

-

Feed Rate:

-

12-40m/min

-

Working Pressure:

-

0.8Mpa

-

Sheet Thickness:

-

10-60nm

-

Total Power:

-

20kw

-

Edge Thickness:

-

0.4-3mm

-

Overall Size:

-

9600x1000x1600

-

Sheet Width:

-

>=80

-

Net Weight:

-

3000k

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Factory brand

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5500*2750*2300mm

-

Power (kW):

-

18.7KW

-

Weight (KG):

-

380 kg

-

Feed Rate:

-

12-40m/min

-

Working Pressure:

-

0.8Mpa

-

Sheet Thickness:

-

10-60nm

-

Total Power:

-

20kw

-

Edge Thickness:

-

0.4-3mm

-

Overall Size:

-

9600x1000x1600

-

Sheet Width:

-

>=80

-

Net Weight:

-

3000k

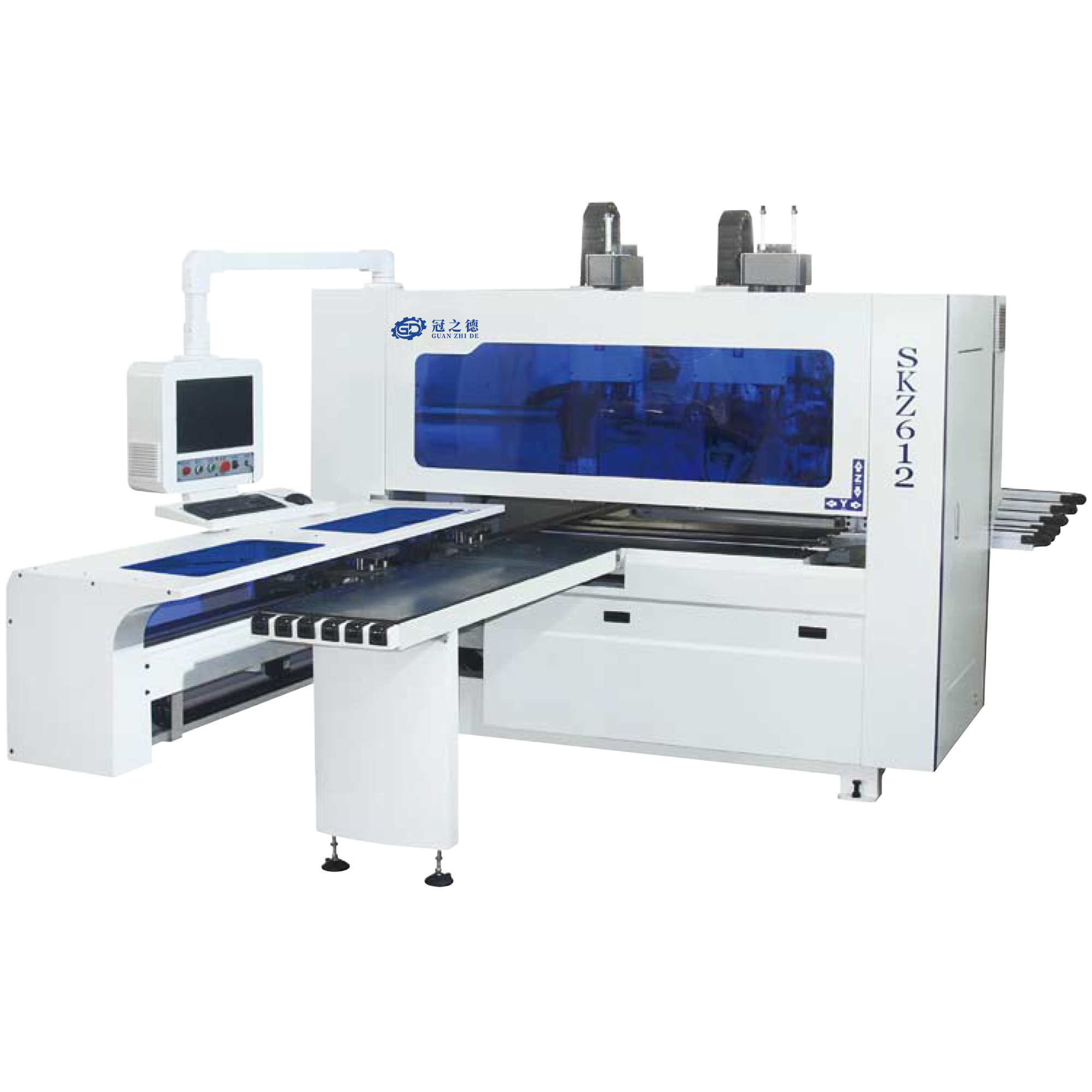

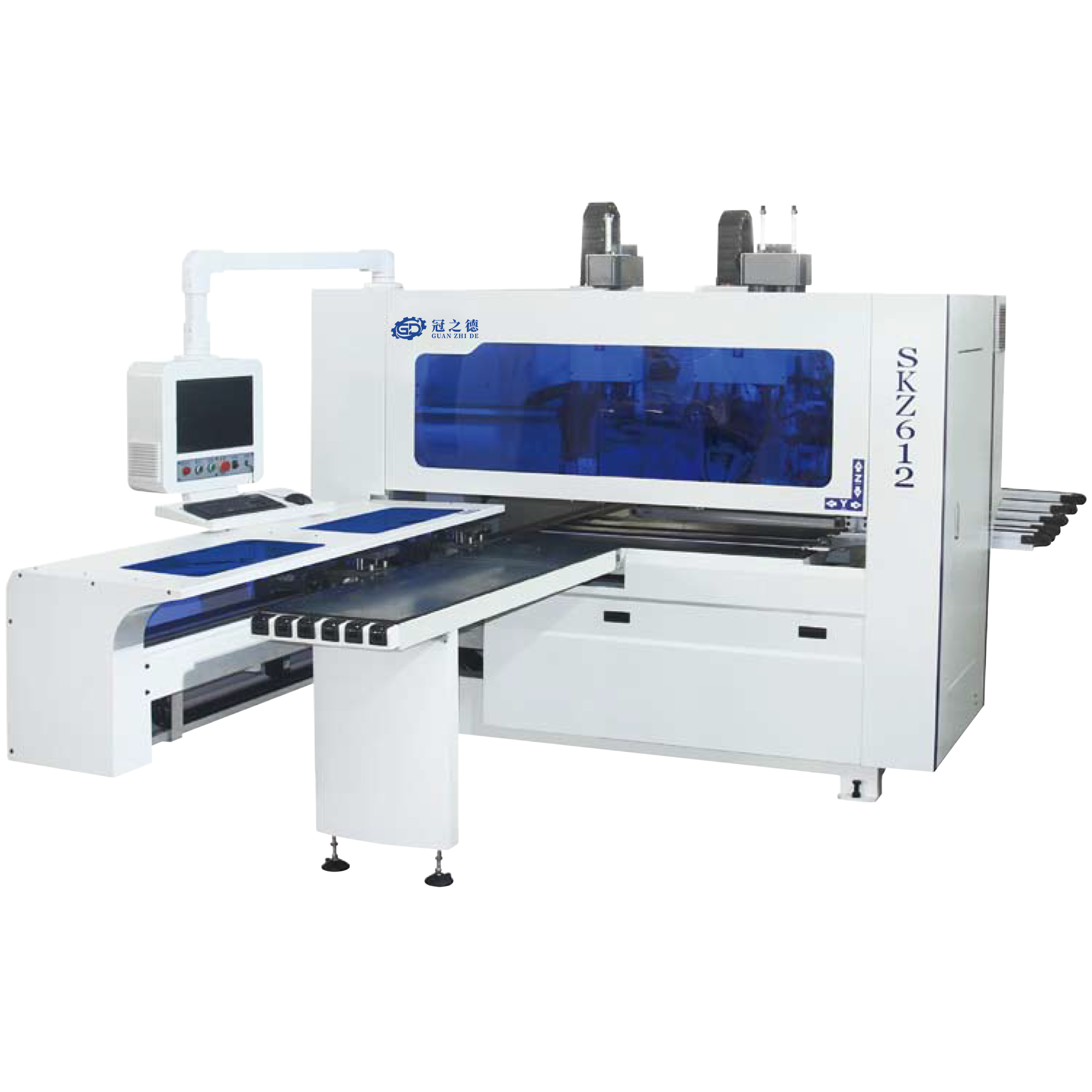

skz612

Product real shot and details

ELECTRICAL AND ELECTRIC BOXES

clear, random with circuit diagram, machine failure, troubleshooting inspection line is simple and convenient

ELECTRICAL AND ELECTRIC BOXES

According to the European CE standards, the whole machine production, wiring, all line number identification is clear, the line is

clear, random with circuit diagram, machine failure, troubleshooting inspection line is simple and convenient

clear, random with circuit diagram, machine failure, troubleshooting inspection line is simple and convenient

ELECTRICAL AND ELECTRIC BOXES

clear, random with circuit diagram, machine failure, troubleshooting inspection line is simple and convenient

MAIN SPINDLE

Brand: Changchua

3.5 KW Air-cooled high-speed spindle 2, speed 18000 rpm/min

GUIDE RAIL AND SLIDER

Good dustproof performance, high precision, heavy load and long service lif

TRANSMISSION

Special custom imported high precision 2 M helical bar, imported high precision reducer, large and stable transmission force, Z

shaft using ball wire rod transmission.

shaft using ball wire rod transmission.

TRANSMISSION

shaft using ball wire rod transmission.

DRIVE AND MOTOR

Low noise and high speed torque. Built-in precision bearing, large torsion, long working time, high resolution and accurate

positioning.

FREQUENCY CONVERTER

The low frequency output torque is large, the motor operation noise is small, the operation balance, the speed precision is high

CONTROL SOFTWARE

The man-machine interface is friendly, easy to operate, scientific system algorithm and fast response time

GAS STORAGE TANKS

High-end machines are equipped with gas cylinders to ensure stable air pressure, in case the machine pressure instability caused

by the normal operation of the equipment, so that the equipment work more stable.

Specification

|

X-axis travel

|

0.15-3mm

|

Drill group power

|

2.2kw×2

|

|

Y-axis travel

|

1800mm

|

Lou milling spindle mode

|

Er3

|

|

Z-axis travel

|

250mm

|

Lou milling speed

|

18000r/min

|

|

Processing wood length

|

70-3050mm

|

Lou milling spindle power

|

3.5kw×2

|

|

Processing wood width

|

30-1200mm

|

Workbench height

|

900mm

|

|

Processing wood thickness

|

10-60mm

|

Lord enters the diameter of the suction pipe

|

150mm

|

|

X-axis max. moving speed

|

150m/min

|

Total power

|

18.7kw

|

|

Y-axis max. moving speed

|

75m/min

|

Operating voltage

|

380V 50HZ

|

|

Z-axis max. moving speed

|

30m/min

|

Working pressure

|

0.6-0.8Mpa

|

|

Drill group vertical drilling

|

5+4

|

Weight

|

3800kg

|

|

Drilling group horizontal drilling

|

Y2×2, X2×2

|

Dimensions

|

5500×2750×2300mm

|

|

Drill down vertically

|

9 支

|

|

|

Factory workshop

Packing & Delivery

Product Description

FOSHAN G&D CNC MACHINERY CO LTD .is an enterprise based on Woodworking equipment manufacturing, which has the high -tech industry development direction. The company has many years of woodworking machinery production experience , its main product”edge banding machine , Precision Panel Saw,six sides drilling machine ”also gets a high reputation in the industry. The company has been adhering to the purpose of “ quality first, customer is supreme”

FAQ

1.How do I order a product that works for me?

We recommend that you consult with our customer service staff before ordering and inform customer service I have a large order, can I place an order first at a low price? In your case, we may charge the normalprice in the first order, but we guarantee that the difference will be refunded after a certain number of orders are placed.

:2.Can you provide designers to help you design ?

Yes, we can provide you with a technical engineer to complete your solution.Please send us pictures or related scheme sketches on the Internet.

3.Can I produce if I want a different configuration?

Yes ,We are manufacturers and fully support customization! Customers who require customization will check the details with our sales staff in advance to avoid deviations and errors!

4.What is the delivery time?

Normal 380V voltage 10-15 days, other voltage is 15 days.

5.What is the payment term?

:2.Can you provide designers to help you design ?

Yes, we can provide you with a technical engineer to complete your solution.Please send us pictures or related scheme sketches on the Internet.

3.Can I produce if I want a different configuration?

Yes ,We are manufacturers and fully support customization! Customers who require customization will check the details with our sales staff in advance to avoid deviations and errors!

4.What is the delivery time?

Normal 380V voltage 10-15 days, other voltage is 15 days.

5.What is the payment term?

T/T 30% in advance and balance before shipment, LC or by negotiation.

6.What is the guarantee?

12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free. Out of 12 months, you will get spare parts at cost price. You will also get technical support and service all the lifetime.

7.What is the technical support?

1) Technical support by phone, email or MSN/Skype around the clock

2) Friendly English version manual

3) Engineer available to service machinery oversea

8.What is the after sales services?

you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and

consultation, technical support and service by email/fax/tel etc. We can also send our engineer to your factory, but need you take charge of all travelling cost and labour cost 100USD/day

6.What is the guarantee?

12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free. Out of 12 months, you will get spare parts at cost price. You will also get technical support and service all the lifetime.

7.What is the technical support?

1) Technical support by phone, email or MSN/Skype around the clock

2) Friendly English version manual

3) Engineer available to service machinery oversea

8.What is the after sales services?

you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and

consultation, technical support and service by email/fax/tel etc. We can also send our engineer to your factory, but need you take charge of all travelling cost and labour cost 100USD/day

Hot Searches