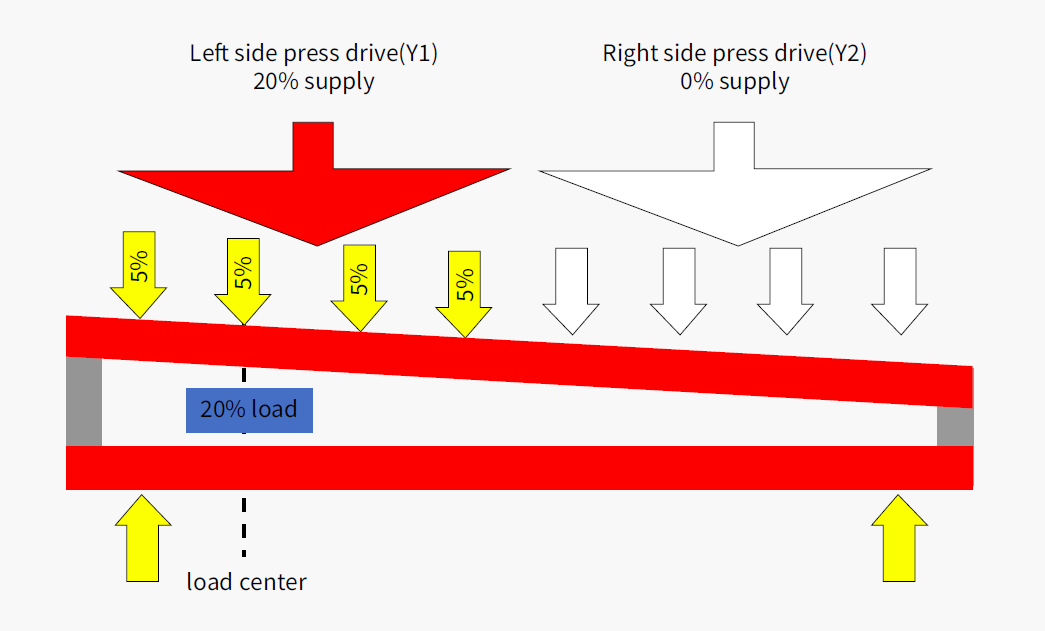

the ability to program all ram position, speeds and ram tilt. The decompression point is also programmable, this feature along with programmable speeds is very useful when bending large sheets.

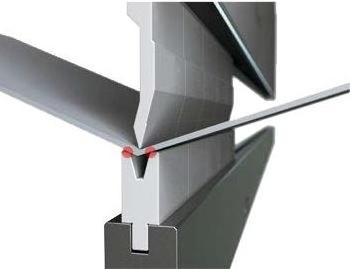

machine. These encoders combined with servo hydraulic valves and the CNC command center, provide a 0.001mm accuracy and