- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

conventional

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

jingguang

-

Model Number:

-

conventional

-

Dimensions(L*W*H):

-

conventional

-

Weight:

-

KG

-

Product name:

-

hot foil stamping printing press machines

-

max working area:

-

750*570 mm

-

wokring pressure:

-

150 t

-

foil delivered length:

-

520mm

-

working speed:

-

1500

-

main motor:

-

2.2KW

-

Over power:

-

10 KW

-

Service Provided:

-

Online support

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Condition:

-

New

-

Plate Type:

-

GRAVURE

-

Color & Page:

-

Multicolor

-

Voltage:

-

conventional

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

jingguang

-

Model Number:

-

conventional

-

Dimensions(L*W*H):

-

conventional

-

Weight:

-

KG

-

Product name:

-

hot foil stamping printing press machines

-

max working area:

-

750*570 mm

-

wokring pressure:

-

150 t

-

foil delivered length:

-

520mm

-

working speed:

-

1500

-

main motor:

-

2.2KW

-

Over power:

-

10 KW

-

Service Provided:

-

Online support

-

After-sales Service Provided:

-

Video technical support

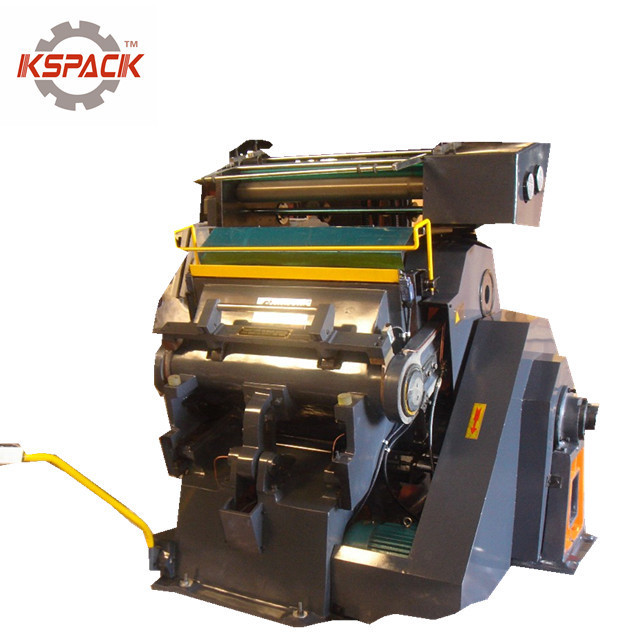

hot foil stamping printing press machines

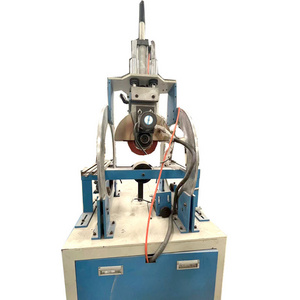

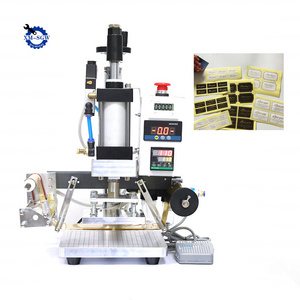

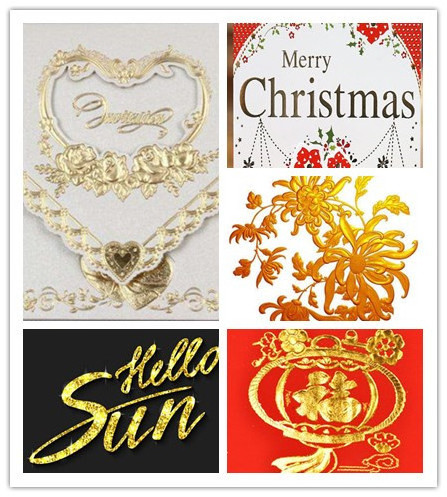

This Hot foil stamping and cutting machine/Hot press gold stamping machine is a kind of special equipment used for thermo-printing and creasing various products, such as cardboard, leather and plastic etc .It is suitable for thermo-printing various paper products with electrochemical aluminum(Aluminum Foil) and also used as a creasing and die cutting machine for mould cutting and creasing cardboardcases and boxes. Concave-convex thermo-printing of various high-grade and fine printed products can also be conducted on this machine for obtaining stereoscopic exquisite and beautiful packing and decorating

1.High strength due to one-piece casting by using top-ranking materialfor machine body.

2.Single plate electromagnetic clutch is sensitive and reliable.

3.Computer controlled is stable to get higher quality stamping effect

4.Operation height is reasonable arranged,moving-bed is optimum.

5.Accurate skip makes saving foil.

6.With three functions of continuous creasing and cutting, opening dwell operation

and closing dwell operation and a large dwell adjusting range.

7.Safety protection system is reliable.

8.This machine has three functions:Creasing ,cutting ,stamping in the same time.

9.Centralized lubrication system get better lubrication and less abrasion .

| Model | 1400 | 930 | 750 |

| Max platen working area | 1040*720mm | 930*670mm | 750*570mm |

| Max Gilding Printing area | 1040*720mm | 930*670mm | 750*570mm |

| Skip order range | built in processing with computer | built in processing with computer | built in processing with computer |

| Working pressure | 220 t | 170 t | 150 t |

| Foil-delivered length | 800 mm | 640 mm | 520 mm |

| Foil-delivered groups | 3 groups | 3 groups | 2 groups |

| Working speed | 1200 pcs/hour | 1320 pcs /hour | 1500 pcs / hour |

| Main motor | 5.5 KW | 4 KW | 2.2KW |

| Overall Dimensions | 2000*1950*2300 | 1760*1670*1670 | 1200*1640*1600 |