- Product Details

- {{item.text}}

Quick Details

-

Function:

-

Acid-Resistant, Antibacterial, Firebrick, Heat Insulation, Non-Slip, Wear-Resistant

-

Surface Treatment:

-

Full Body Tiles

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

DFO

-

Model Number:

-

DFOWT0012322

-

Type:

-

Tiles

-

Product Name:

-

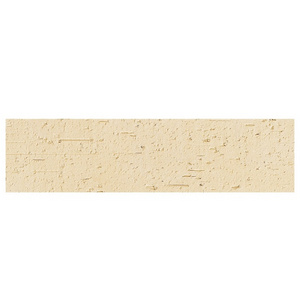

flexible composites wall tile

-

Light weight:

-

5Kg/sqm

-

waterproof:

-

fire-resistant

-

usage:

-

exterior and interior

-

freeze resistant:

-

durable

-

long life:

-

>30 years

Quick Details

-

Project Solution Capability:

-

graphic design

-

Application:

-

Villa

-

Design Style:

-

Modern

-

Function:

-

Acid-Resistant, Antibacterial, Firebrick, Heat Insulation, Non-Slip, Wear-Resistant

-

Surface Treatment:

-

Full Body Tiles

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

DFO

-

Model Number:

-

DFOWT0012322

-

Type:

-

Tiles

-

Product Name:

-

flexible composites wall tile

-

Light weight:

-

5Kg/sqm

-

waterproof:

-

fire-resistant

-

usage:

-

exterior and interior

-

freeze resistant:

-

durable

-

long life:

-

>30 years

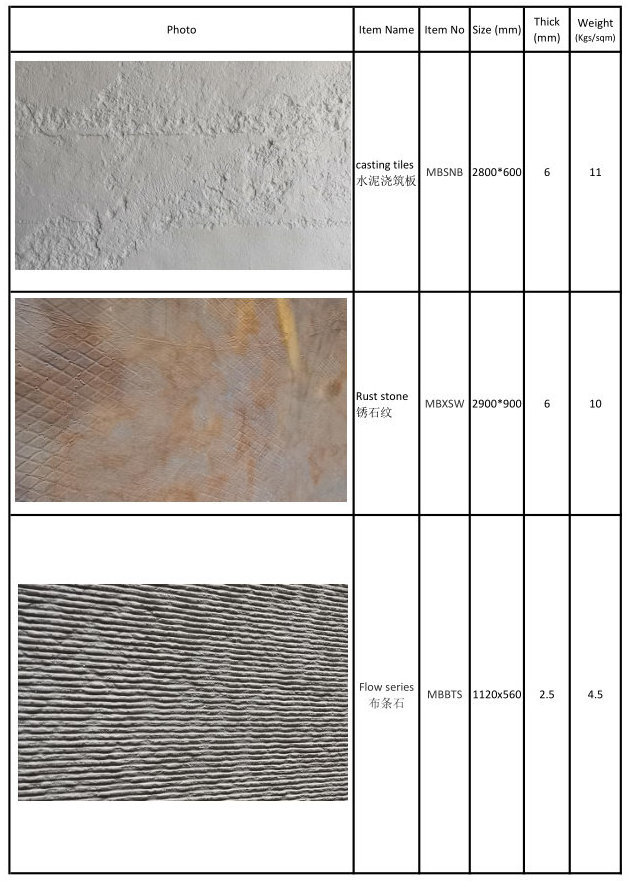

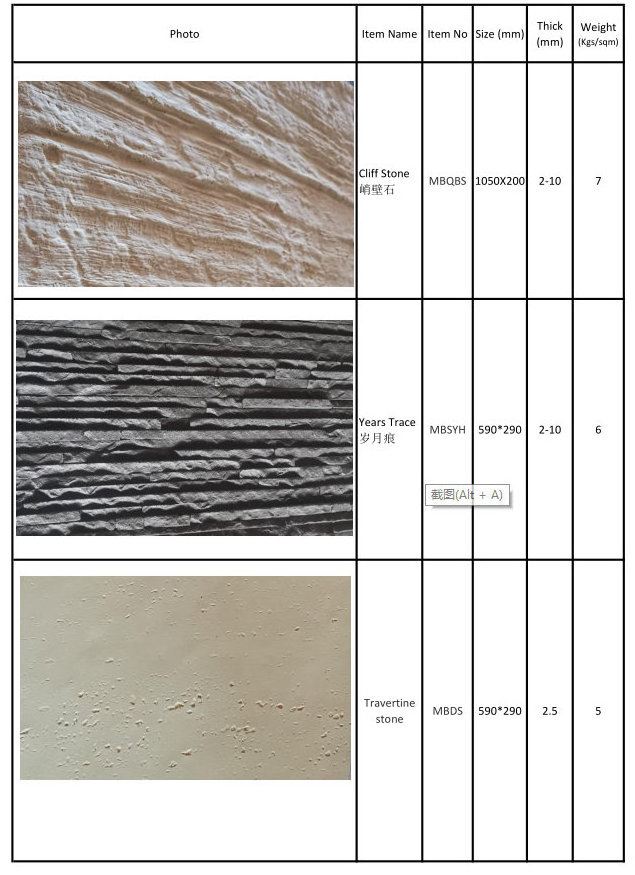

long life light flexible wall external tile

long life light flexible wall external tile

|

Tile type |

Flexible Clay Composites Wall Tiles |

|

Size |

300x600,600x1200, 600x2400, 600x2800,900x2900mm |

|

Thickness |

About 3mm, weight: about 5Kgs/sqm |

|

Composition |

Plastic, clay and mineral powder, quartz sand, fiberglass, etc |

|

Color |

all kinds of color according to your requirement |

|

Usage |

Interior and Exterior wall decoration |

|

Packaging: |

By cartons |

|

Delivery time |

Within 2weeks |

|

Payment terms |

T/T 50% deposit, 50% against the B/L copy. |

|

Supply ability |

60000square meters per month |

|

Remark |

All kind of designs can be produced according to your requirements |

Usage:

Indoor and outdoor decoration of office buildings, hospitals, shops, restaurants, bars and other public buildings;

All kinds of new and old building constructions of indoor and outdoor decoration;

Particularly suitable for high-rise building exterior wall insulation decoration.

Interior and exterior wall decoration of family homes, luxury apartments, villas etc;

Advantages:

Lightweight, anti-seismic, high security;

Flame-retardant, smokeless, excellent fireproof performance;

Superior chemical stability, make products get self-cleaning, and get longer acid resistance, durability and weather ability;

Energy-saving and low carbon, eco-friendly and healthy, suitable for both inside and outside decoration;

Potential saving the construction area, thickness only 1/3 thick of traditional brick wall;

Excellent flexibility, super separation strength and impact resistance;

Intelligent performance on breathable, antibacterial, water-proof, anti-cracking;

It can use for renovation of the old building decoration directly;

Easy-installation, colorful, high-strength natural effect;

How to install?

It can be easy to cut into any shape and sizes as your request.

And it can glue with adhesive same as the normal wall tiles, no special materials request.

1)Spread Tile Adhesive mixture to the tiles

Snap the line, and stick cement adhesive mixture to back side of the tiles. Adhesive mixture should be evenly applied and the thickness should be 2-3 mm, and adhesive area should cover more than 85%.

2)Fill the joints

The joints should be filled by special cement-based gap filler or silicone adhesive meeting National Standard. The adhesive mixture is not allowed to fill the joints directly to avoid alkali efflorescence.

3)Point Joints

The joints should be made by copper rod, and the joints should be dished, smooth, plump.

4)Clean wall tiles

Clean the dirt of joint filler or cement mortar on surface and sides of the tiles before setting, mapping by dry sponge or scratching by plaster trowel. Fabric cloth with water is not allowed, or else resulting in alkali efflorescence.

5)Process Exterior Corners

1.Hitom edge is on the left side of the interface, with a smooth seam sealant.

2.Make 45°Diagonal by rotary sander, and match two tiles correctly.

3.Lapping joints is not allowed at exterior joints when tiles are thin. For lapping joints, 2-3 mm seam should be made at the lapping. The seam should be filled by joint fillers and someone must be put in charge of the work, then painted by coating of same color.

Test report from as below:

1)VOC Test

2)Impact Test

3)Freeze thaw cycling test

4)Anti abrasion test

5) Water Absorption and Density test: 5.4% and 1920Kgs/M3

6) Working Temperature Test: -40- +80C

For any further info, please contact me: