- Product Details

- {{item.text}}

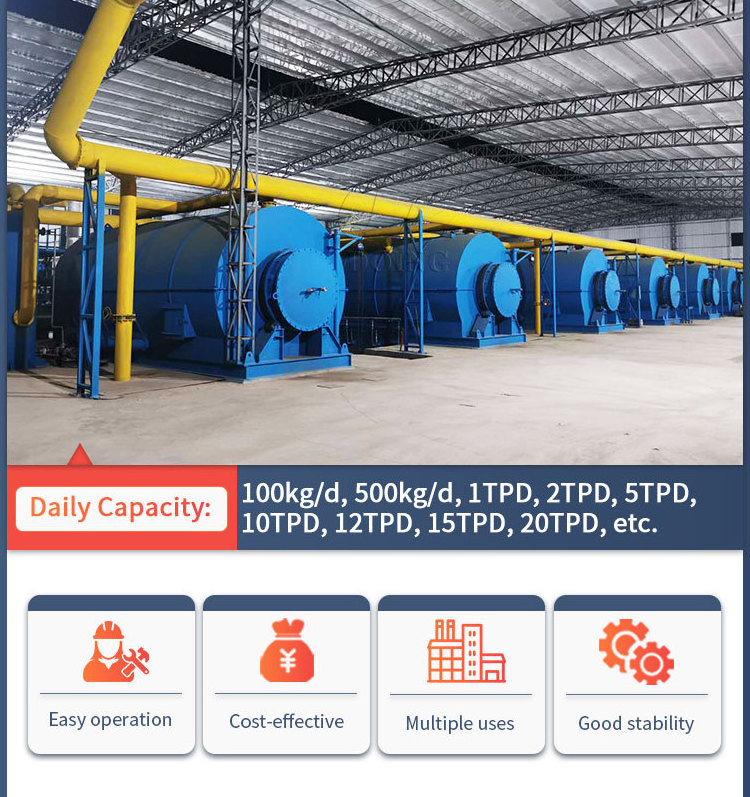

Quick Details

-

Productivity:

-

Other

-

Weight (KG):

-

2000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Voltage:

-

220V,380V,440V

-

Machine type:

-

continuous/batch/semi-continuous

-

Material:

-

Q245R

-

Thickness:

-

16mm

-

Cooling Mode:

-

water cooling

-

Certification:

-

: ISO, CE

-

Quality control:

-

heat treating workship,X-ray test for welding crack line

-

Color:

-

Customized Color

-

Application:

-

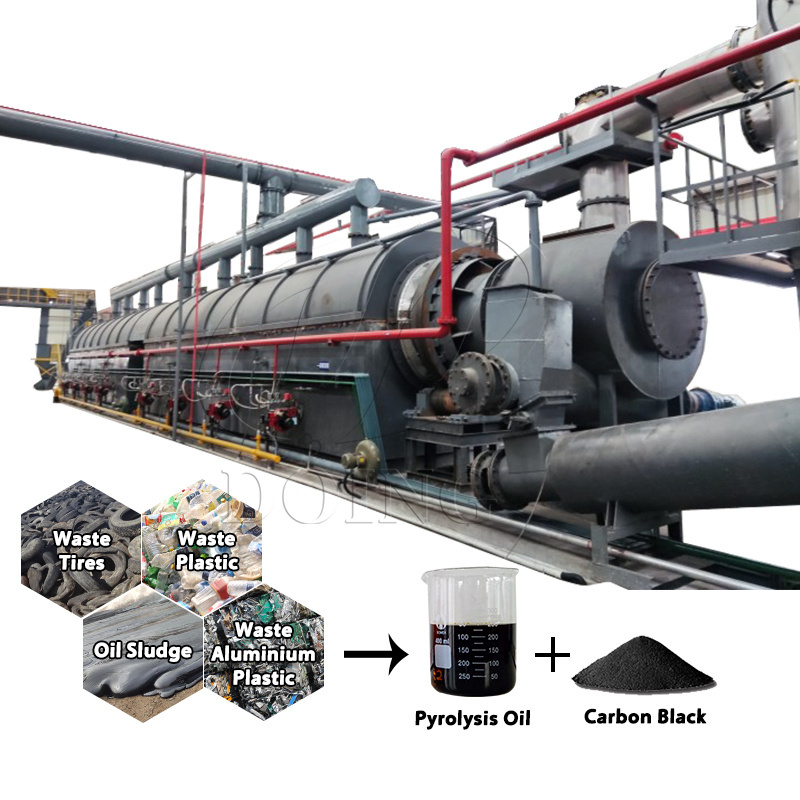

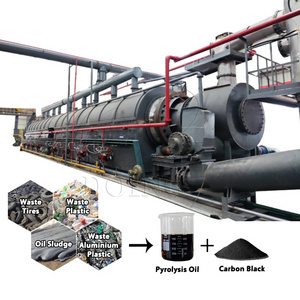

waste sludge/tire/plastic pyrolysis

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DOING

-

Size:

-

4*2.5*2.8

-

Productivity:

-

Other

-

Weight (KG):

-

2000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Voltage:

-

220V,380V,440V

-

Machine type:

-

continuous/batch/semi-continuous

-

Material:

-

Q245R

-

Thickness:

-

16mm

-

Cooling Mode:

-

water cooling

-

Certification:

-

: ISO, CE

-

Quality control:

-

heat treating workship,X-ray test for welding crack line

-

Color:

-

Customized Color

-

Application:

-

waste sludge/tire/plastic pyrolysis

Product Parameters

Scheme 1: New design continuous type pyrolysis plan

t

|

Item

|

Continuous Pyrolysis Plant

|

|

|

||

|

Model

|

DY-C-30

|

DY-C-50

|

DY-C-100

|

||

|

Cpacity

|

30T/D

|

50T/D

|

100T/D

|

||

|

Power

|

65Kw

|

80Kw

|

120Kw

|

||

|

Working type

|

Continuous

|

|

|

||

|

Reactor deisgn

|

Mutiple reactors (The quantity and size depends on the raw material condition)

|

|

|

||

|

Rotating

|

Internal rotating

|

|

|

||

|

Cooling system

|

Recycled waster cooling

|

|

|

||

|

Reactor material

|

Q245R/Q345R boiler plate

|

|

|

||

|

Heating method

|

Indireact hot air heating

|

|

|

||

|

Heating fuel

|

Fuel oil/gas

|

|

|

||

|

Feedstock

|

Waste tire/plastic/rubber

|

|

|

||

|

Output

|

Fuel oil, carbon black

|

|

|

||

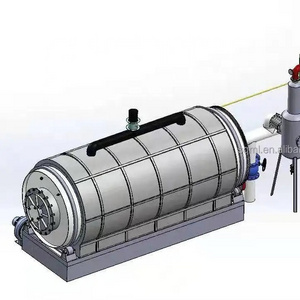

Scheme 2: Cost-effective batch type pyrolysis plant

|

Items

|

Batch Pyrolysis Plant

|

|

|

||

|

Equipment type

|

DY-1-6

|

DY-1-10

|

DY-1-12

|

||

|

Raw material

|

Waste plastics, tyres

|

Waste plastics, tyres

|

Waste plastics, tyres

|

||

|

Structural form

|

Horizontal rotation

|

Horizontal rotation

|

Horizontal rotation

|

||

|

24-hour Capacity

|

6 ton

|

10 ton

|

12 ton

|

||

|

Oil yield

|

2.7-3.3ton

|

4.5 -5.5ton

|

4.8 -6.6ton

|

||

|

Operating pressure

|

Normal

|

Normal

|

Normal

|

||

|

Material of pyrolysis Reactor

|

Q245R

|

Q245R

|

Q245R

|

||

|

Thickness of pyrolysis Reactor

|

16mm

|

16mm

|

16mm

|

||

|

Rotate speed of pyrolysis Reactor

|

0.4turn/minute

|

0.4turn/minute

|

0.4turn/minute

|

||

|

Total power

|

15KW

|

15KW

|

15KW

|

||

|

Mode of cooling

|

Water cooling

|

Water cooling

|

Water cooling

|

||

|

Cooling area of condenser

|

100sqm

|

100sqm

|

100sqm

|

||

|

Kind of transmission

|

Internal gear drive

|

Internal gear drive

|

Internal gear drive

|

||

|

Noise dB(A)

|

≤85

|

≤85

|

≤85

|

||

|

Size of Reactor(D×L)

|

2200×6000

|

2600×6600

|

2800×6600

|

||

|

Working form

|

Intermittent operation

|

Intermittent operation

|

Intermittent operation

|

||

|

Delivery time

|

20days

|

20days

|

20days

|

||

|

Weight

|

27T

|

32T

|

35T

|

||

Scheme 3: Free installation small scale pyrolysis plant unit

Raw Materials & Oil Yields

Waste oil processing process

Project Case

Customer Feedback

Our services

Hot Searches