- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

Depends on your specific items

-

Dimension(L*W*H):

-

Depends on your specific items

-

Weight:

-

Depends on your specific items

-

Keyword:

-

machine make toilet paper

-

Output product:

-

tissue paper, napkin paper, ficial tissue paper

-

Raw material:

-

Waste paper,Oure wood pulp

-

Paper weight:

-

13-30g/m2

-

Paper width:

-

787-900mm;

-

Width of cylinder mould:

-

1100mm

-

Work speed:

-

40-70m/min

-

Design speed:

-

80m/min

-

Design Standards:

-

CNS Export equipment

Quick Details

-

Production Capacity:

-

0.8-1t/d

-

Place of Origin:

-

Henan, China(Mainland)

-

Brand Name:

-

Shunfu

-

Voltage:

-

380V

-

Power:

-

Depends on your specific items

-

Dimension(L*W*H):

-

Depends on your specific items

-

Weight:

-

Depends on your specific items

-

Keyword:

-

machine make toilet paper

-

Output product:

-

tissue paper, napkin paper, ficial tissue paper

-

Raw material:

-

Waste paper,Oure wood pulp

-

Paper weight:

-

13-30g/m2

-

Paper width:

-

787-900mm;

-

Width of cylinder mould:

-

1100mm

-

Work speed:

-

40-70m/min

-

Design speed:

-

80m/min

-

Design Standards:

-

CNS Export equipment

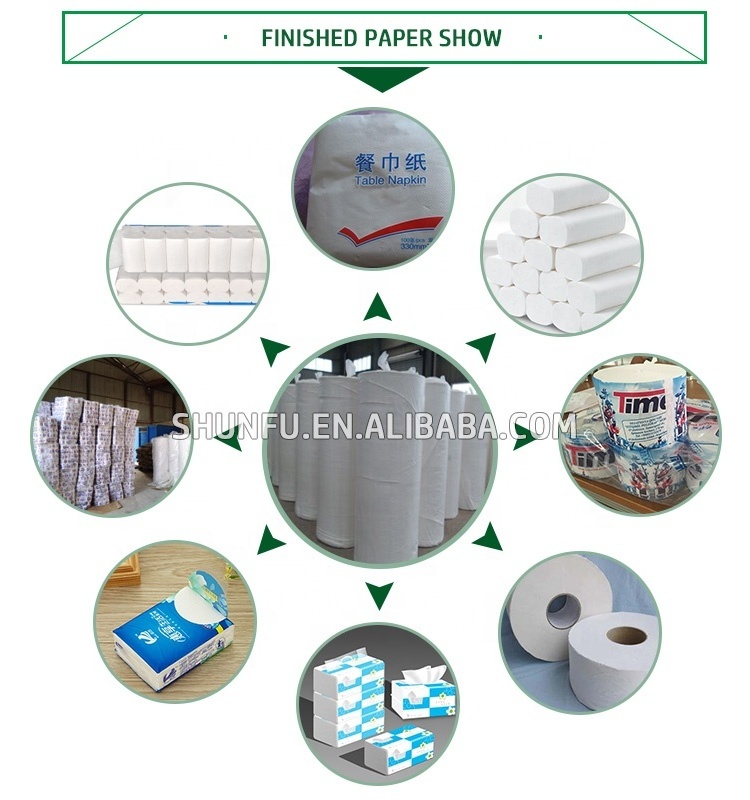

Small Manufacturing Machine Make Toilet Paper Plant Manufacturer

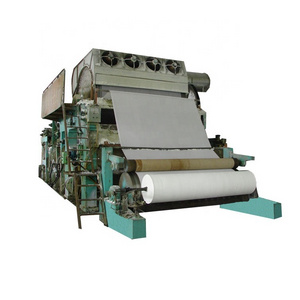

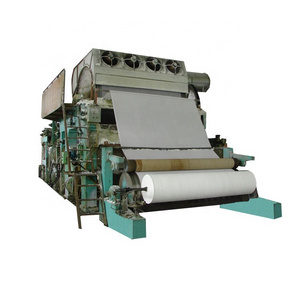

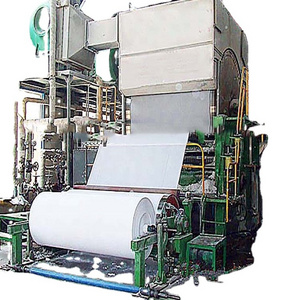

∇. MACHINE MAKE TOILET PAPER PROFILE

There are many models and different capacity toilet tissue making machines production line, Such as 787/1092/1575/1800/2000/2400/3600 model and so on. toilet tissue making machines also called: paper machine,tissue machine, tissue rewinder,paper making machine,toilet roll rewinder,toilet roll machine,toilet tissue machine,kitchen towel machine,kitchen towel rewinder Toilet paper machines etc.

∇. TECHNICAL PARAMETERS

| Raw material | Waste paper; wood pulp board |

| Output paper style | Toilet paper; tissue paper |

| Paper weight | 13-30g/m2 |

| Paper width | 787-900mm |

| Width of cylinder mould | According to actual |

| Capacity | 0.8-1T/D |

| Design speed | 70-100m/min |

| Work speed | 80m/min |

| Design Standards | CNS export equipment |

| Machine specifications | Upside down slurry form |

∇. RAW MATERIALS

The following raw materials is made into paper pulp with paper pulp equipments (such as hydrapulper etc.), then paper pulp is made into paper with small scale toilet paper making machine

∇. MAIN COMPONENT FOR MACHINE MAKE TOILET PAPER

1. Dryer is used for drying the moisture in the paper and to decorate the paper surface in tissue paper making machine facial

2. Pulp pump is used for extracting the paper pulp in tissue paper making machine facial

3. Cylinder mould is used for improving paper quality in tissue paper making machine facial

4. Roller is used for dehydrating and supporting mesh in Tissue Paper Machine

5. Dryer exhause hood function is to gathere steam in Tissue Paper Machine

PS: The main parts model is depends on the small scale toilet paper making machine ,tissue paper make machinery of china,toilet paper maker machine,tissue paper making machine facial,small toilet paper roll machine,tissue paper machine configuration.

STEP 1. JUMBO ROLL PAPER

The paper pulps is made into jumbo roll paper with tissue paper machine.

STEP 2. SMALL ROLL DAILY TISSUE PAPER

Then jumbo roll paper is made into the following final paper with paper converting process machines, such as rewinding machine, cutting machine, packing machine and so on. The above is the whole paper making processing.

∇. MAIN PRODUCTS INTRODUCTION

Shunfu Paper Making Machinery Co.Ltd is located in Henan Province,our factory has established about 30 years, which specializing in paper making machine, paper processing machine and paper machine. Our products include:

- Tissue paper making machine

- Kraft paper making machine

- Paper rewinder machine

- Paper cutting machine

- Paper calender machine

- Cylinder mould

- Dryer cylinder

EXAMPLE 1. TOILET JUMBO ROLL PAPER COVERTING PROCESSING

- Put the jumbo roll paper produced from paper machine to convey into toilet paper rewinding machine

- Then to process into automatic log cutting machine to produce small toilet roll

- Then put the small toilet roll into plastic bag for one roll packing

- Finally put packed paper roll into big plastic bag and sealed by sealing machine

EXAMPLE 2. NAPKIN PAPER COVERTING PROCESS

- Put the jumbo roll paper produced from paper machine convey into slitting and rewinding machine to cut well rolled paper

- Then to print,emboss and automatically fold the rolled paper which is cut well into square or rectangular napkin paper

- Finally put napkin paper into napkin paper packing machine to pack into soft packed drawing napkin paper

About more products, pls click here!