- Product Details

- {{item.text}}

Quick Details

-

Solid content:

-

40-45%

-

PH value:

-

6.5-7.5

-

Package:

-

50kg/200kg/1000kg

Quick Details

-

CAS No.:

-

3254687-6

-

Place of Origin:

-

Shandong, China

-

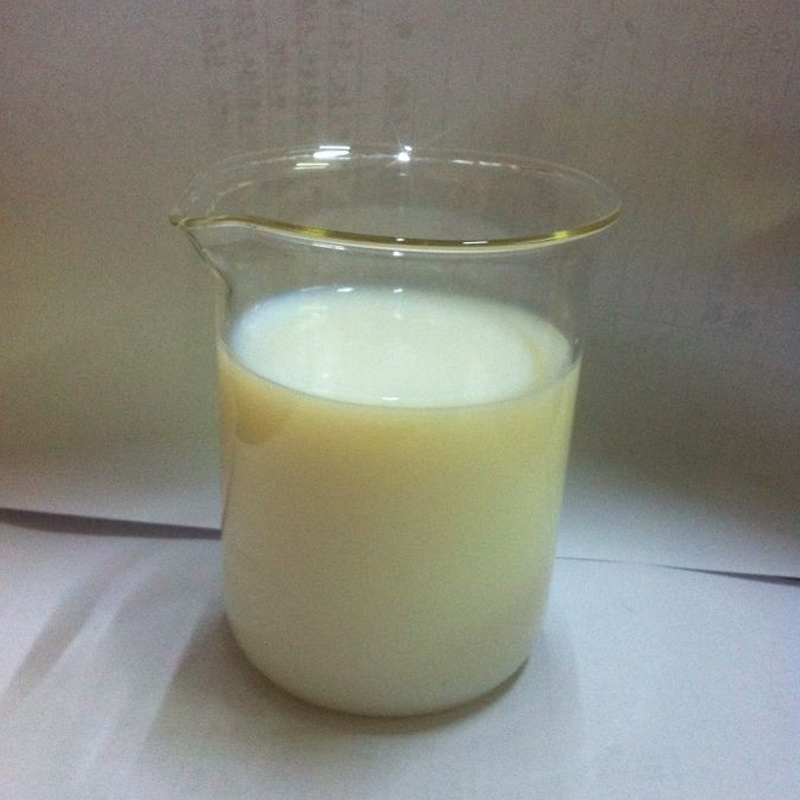

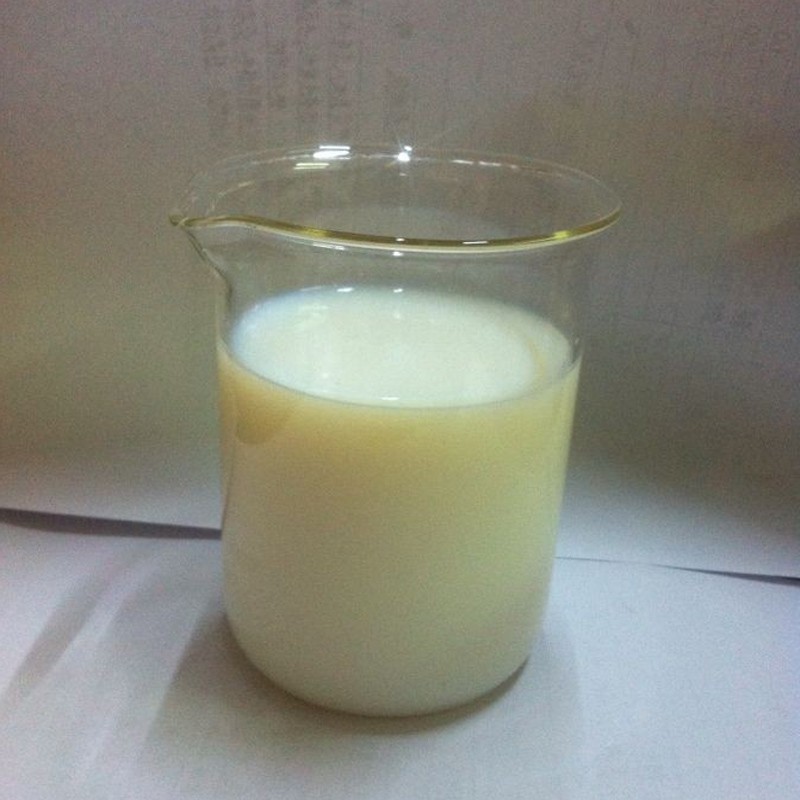

Appearance:

-

White liquid

-

Solid content:

-

40-45%

-

PH value:

-

6.5-7.5

-

Package:

-

50kg/200kg/1000kg

Product introduction

D400 is water based acrylic polymer emulsion adhesive designed for dry lamination BOPP/PET film to paper process.Dry bond lamination is the process of coating the adhesive to plastic film, drying the adhesive with heat and air flow and then laminating the adhesive to a second substrate(paper/paper board/cardboard etc..) via a heat compression nip.

Advantage

1. Lower consumption than oil / solvent based lamination adhesives.

2. water based adhesive, free of toluene, eco-friendly.

3. Easy to clean the lamination equipment.

4. Can be use for highest speed automatic dry lamination machine.

5. It is mono-component adhesive with very good adhesion to flexible film .

6. We offer different viscosity adhesive, to meet slow, middle and high speed machine,

7. it can be used for manual, semi-auto, automatic and high speed full automatic lamination machines.

Technical Parameter

Suggestion

:

1, Before lamination, raise the temperature of the laminating machine roller to 95-115℃, the temperature of the drying tunnel to 80-95℃.

2, Pour the laminating adhesive into the glue tank, start the roller to keep the adhesive disperse on roller evenly,

The amount of adhesive consumption shall be flexibly adjusted according to the paper or film need to be laminated.

3, After complete drying the adhesive on film, the real temperature of the roller shall be 80-95℃, the roller pressure shall be around 6-18kgs.

4, the pressure roll shall be controlled flexibly to ensure no adhesive overflow from both sides of film and connections

Notice

:

1, Clean the adhesive tank and roller before use our adhesive;

2, Do not mix our adhesive with other adhesives;

3, Our adhesive only apply for BOPP film with corona over 38 Dyne ;

4, Better make testing for with film or paper, before mass production, to check the color retention or bonding strength;

Packing

(1), 50kgs/Plastic drum, 20650kgs/1x20'GP without pallet. 13500kgs/1x20`gp withou pallet.

(2), 200kgs/drum,16000kgs/1x20'GP

(3), 1000kgs/IBC, 20000kgs/1x20'GP