- Product Details

- {{item.text}}

Quick Details

-

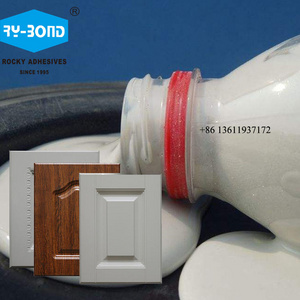

Brand Name:

-

INNOVATE

-

Model Number:

-

5133

-

Type:

-

vacuum membrane glue

-

Product name:

-

vacuum membrane press wood glue

-

PH:

-

7

-

Material:

-

Epoxy Resin+hardener

-

Application:

-

MDF, Interior door, cabinet, wardrobe

-

Package:

-

Customized Package

-

Certificate:

-

MSDS RoHS

-

Color:

-

White

-

Function:

-

Construction, Woodworking, PVC bonding wood

-

Feature:

-

Good heat resistance,Fast drying performance,Super bonding strength

-

MOQ:

-

200kgs

Quick Details

-

CAS No.:

-

124544796786

-

Other Names:

-

membrane press glue

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

INNOVATE

-

Model Number:

-

5133

-

Type:

-

vacuum membrane glue

-

Product name:

-

vacuum membrane press wood glue

-

PH:

-

7

-

Material:

-

Epoxy Resin+hardener

-

Application:

-

MDF, Interior door, cabinet, wardrobe

-

Package:

-

Customized Package

-

Certificate:

-

MSDS RoHS

-

Color:

-

White

-

Function:

-

Construction, Woodworking, PVC bonding wood

-

Feature:

-

Good heat resistance,Fast drying performance,Super bonding strength

-

MOQ:

-

200kgs

Product parameters

|

Name and model

|

Solid content %

|

Viscosity mPas(27℃)

|

PH

|

Application range and features

|

||||

|

3105

|

48.0~52.0

|

2000~3000

|

6~9

|

General-purpose product. Good for any vacuum forming techniques.

Applied products: cupboards, paint-free door industry.

Features:low activating temperature, good instant viscosity, good for spraying, leaving smooth surface.

|

||||

|

3118

|

48.0~52.0

|

2000~3000

|

6~9

|

General-purpose product. Good for any vacuum forming techniques.

Applied products: cupboards, paint-free door industry.

Features:low activating temperature, good viscosity, large operation range, good temperature tolerance.

|

||||

|

5133

|

48.0~52.0

|

2000~3000

|

6~9

|

General-purpose product. Good for any vacuum forming techniques.

Applied products: cupboards, paint-free door industry.

Features:low activating temperature, good viscosity, large operation range, good temperature tolerance.

|

||||

|

5188

|

48.0~52.0

|

2000~3000

|

6~9

|

General-purpose product. Good for any vacuum forming techniques.

Applied products: cupboards, paint-free door industry.

Features:low activating temperature, good viscosity, large operation range, good temperature tolerance.

|

||||

|

5121

|

41.0~45.0

|

500~1000

|

6~9

|

General-purpose product. Good for any vacuum forming techniques.

Applied products: cupboards, paint-free door industry.

Features:low activating temperature, good viscosity, large operation range, good temperature tolerance.

|

||||

|

5123

|

41.0~45.0

|

500~1000

|

6~9

|

Specially designed for paint-free door products.

Features: can be used without curing agent, high temperature tolerance, particle is small, good for spraying, smooth surface formed afterwards.

|

||||

|

Activation temperature

|

Not less than 55℃

|

|

|

|

||||

|

Container

|

12barrels/layer, 3layers/pallets, 10pallets/ 20 ft container

|

|

|

|

||||

|

Min Pressing Time

|

3-5 minutes

|

|

|

|

||||

|

MOQ

|

500KGS

|

|

|

|

||||

|

Serve

|

OEM and ODM

|

|

|

|

||||

|

Payment

|

T/T, 30%deposit, the rest should be paid before the delivery

|

|

|

|

||||

|

|

|

|

|

|||||

Product Description

Requirements of technical conditions:

Sufficient cleaning for the applying surfaces.

Methods of applying: spraying, manual brushing.

Water content of applying material: < 7~ 15%.

Operation environment temperature: best temperature is around 20 ℃. When environment temperature < 5 ℃, increase the temperature of the material and glue.

Product applying amount: flat surface 40-60g/m2, tank or frame 80-100g/m2.

Can be used on its own. If mixed with curing agent would have better temperature tolerance. (curing agent YL-3100)

Curing agent amount (if use together): 2-5%

Cleaning: before completely dried, clean with water.

Storage and delivery:

room temperature storing. Shelf-life: half a year in 5-35 ℃ without freezing or direct sun. Not dangerous product, can be transported as normal goods.

Note

: this page does not include all the products. Please get in touch for more products information.

Application

Hot Searches