- Product Details

- {{item.text}}

Quick Details

-

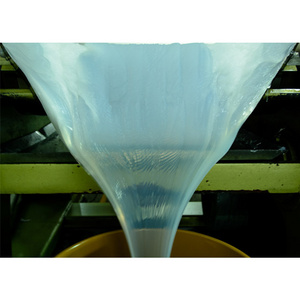

Appearance:

-

Transparent, no extraneous matter.

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

DJSilicone

-

Model Number:

-

NE-96

-

Appearance:

-

Transparent, no extraneous matter.

![]()

| Properties | Product Data | Test Method | |||||

| NE-9640 | NE-9650 | NE-9660 | NE-9670 | NE-9680 | |||

| Appearance | Transparent, no extraneous matter. | Visual Inspection | |||||

| Density, g/cm³ | 1.09~1.15 | 1.12~1.18 | 1.14~1.20 | 1.17~1.23 | 1.18~ 1.25 | ASTM D792 | |

| Curing | Hardness, Shore A | 40±2 | 50±2 | 60±2 | 70±2 | 80±2 | ASTM D2240 |

| Tensile Strength, MPa≥ | 8.0 | 8.5 | 8.0 | ASTM D412 | |||

| Elongation at Break, % ≥ | 500 | 400 | 300 | 200 | |||

| Tension Set, % ≤ | 10 | ||||||

| Tear Strength, Die C kN/m ≥ | 20 | 25 | 20 | ASTM D624 | |||

| Post-Curing | Hardness, Shore A | 45±2 | 57±2 | 68±2 | 76±2 | 85±2 | ASTM D2240 |

| Tensile Strength, MPa≥ | 7.5 | 8.0 | 7.0 | ASTM D412 | |||

| Elongation at Break, % ≥ | 400 | 350 | 260 | 150 | |||

| Tear Strength, Die C kN/m ≥ | 18 | 16 | ASTM D624 | ||||

| Compression Set, 180°C*22h % ≤ | 45 | 35 | 30 | ASTM D395 | |||

| Rebound Resilience, % ≥ | 50 | 45 | 40 | / | |||

| Volume Resistivity, Ω·cm ≥ | 1x10 15 | IEC 60093 | |||||

| Dielectric Strength, kV/mm ≥ | 20 | IEC 60243 | |||||

|

• Physical data in the above table is for reference only.

|

|||||||

Characteristics

• Good transparency and mechanical properties

• Good yellowing resistance and stable processability

Main Applications

•They are applicable to manufacturing of various silicone tubes, sealing joint strips, electric wires and cables through extrusion process.

![]()

![]()

![]()