- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HENGXING

-

Dimension(L*W*H):

-

2035x1921x2000mm

-

Weight:

-

6.5t-13t

-

Warranty:

-

12 Months

-

Steel Body:

-

Welded or cast frame in choice

-

Color:

-

As Client`s requirements

-

Spare Parts:

-

Supply For Whole Life

-

Manufacture Standard:

-

Strictly by china mining machine industry

-

Spare parts supply:

-

Lifelong Time

-

Max feeding size:

-

210mm

-

price:

-

negotiate

-

Product name:

-

PEX 250X1200 Fine Jaw Crusher For Secondary Crushing Plant

-

Certification:

-

ISO9001:2008,CE

Quick Details

-

Application:

-

Mining,construction,ore dressing,engineering, Secondary Crushing

-

Capacity(t/h):

-

10TPH-85TPH

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HENGXING

-

Dimension(L*W*H):

-

2035x1921x2000mm

-

Weight:

-

6.5t-13t

-

Warranty:

-

12 Months

-

Steel Body:

-

Welded or cast frame in choice

-

Color:

-

As Client`s requirements

-

Spare Parts:

-

Supply For Whole Life

-

Manufacture Standard:

-

Strictly by china mining machine industry

-

Spare parts supply:

-

Lifelong Time

-

Max feeding size:

-

210mm

-

price:

-

negotiate

-

Product name:

-

PEX 250X1200 Fine Jaw Crusher For Secondary Crushing Plant

-

Certification:

-

ISO9001:2008,CE

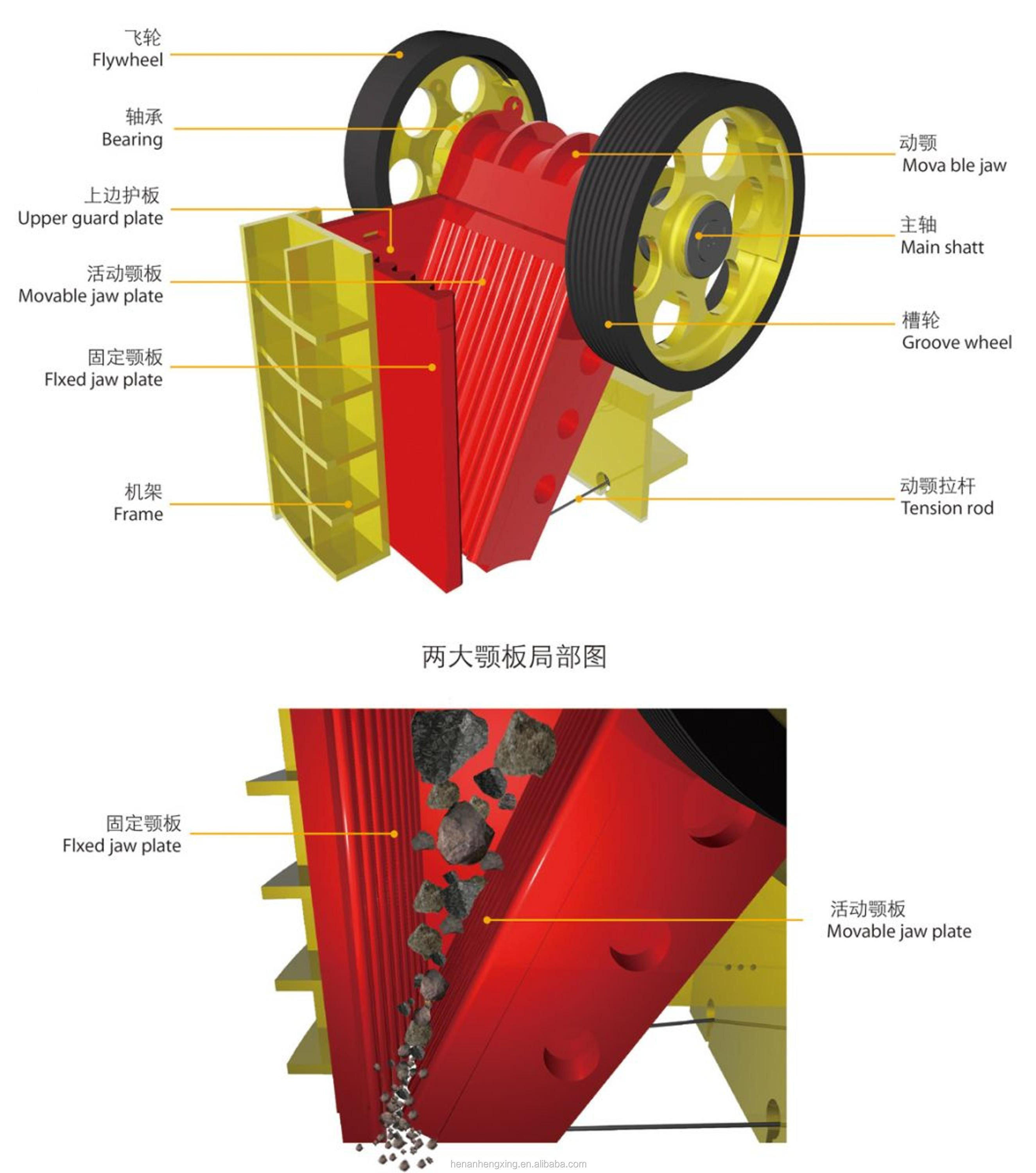

250X1200 Fine Jaw Crusher:

Fine Jaw crusher has cast chassis and welded chassis, and cast steel chassis is durable and it is not easily deformed, but the surface is rough and not enough beautiful, so it is suitable for crushing hard ore. Welded casing is nice, and surface is smooth and easy to clean, also, it is suitable for the occasion with high environmental requirements, but welded chassis is easily deformed, the stiffness is not high enough, so it is more appropriate for crushing brittle material.

Our company manufactures fine jaw crusher. The fine jaw crusher is able to easily crush lump ore, which is applied as secondary crushing machine in plant.

The jaw gap adjustment process on this crusher is easy to do so regular monitoring and closing of the gap will compensate for any wear in the plates. Users find the hardened steel jaw plates very long lasting.

Ideally, single pass fine jaw crushing is the most efficient means to reduce sample size prior to subdivision and fine pulverising.

When you choose jaw crusher, in addition to consider the scale of production, but also consider the size of the raw materials, but also consider whether other ancillary equipment capacity matches with each other.

Application:

pebble, limestone, granite, basalt, diabase, andesite, etc

The working principle of fine jaw crusher:

the motor drive belt and pulley of jaw crusher make the moving jaw move up and down, when the the angle between the jaw plate and moving jaw becomes larger, and promotes the moving jaw plate close to fixed jaw plate, at the same time, the materials are crushed and grinded; when the moving jaw moves down, the angle between bracket and moving jaw plate becomes smaller,the moving jaw plate leaves the fixed plate due to the function of trolley and spring, and then the crushed materials are discharged from the mouth of crushing chamber.

Fine Jaw Crusher model :

|

Fine jaw crusher 250*1000 features:

1.Large crushing ratio and even discharged materials.

2.The adjusting range of discharged outlet is large and reliable,can meet various requirements of customer.

3.Lubrication system is safe and reliable,easy to change the spare parts and convenient maintenance.

4.Simple structure and low operation cost.

jaw crusher 250x1000 packing and delivery :

Pre-sale service

· Process designing

· Freely provide project designing

· Choosing suitable equipment for you

Medium-sales service

· Complete process of export

· Draft the construction scheme and detailed process

· Accompany you to complete the acceptance of the equipment

After-sales service

· Good and fast arrangement for the shipment

· We sent engineer to the scene to guide installation debugging and training operators

Q: For providing you the suitable quotation we need to know the following information:

A: 1.What is the raw material ,is it mountain stones,riverstone ,coal ,slag,or other stones?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product? Once we get your answers, I can provide you the best quotation immediately.

Remarks: The price will depend on different models.

Contact Information

· Contact person: Sara Pang

· Tel:+86 (0)371 67858720

· Skype: sarapang6

wechat: sarapang6

· Mobile phone/WhatAapp:+8613783471727

· Email : sales006*zzhxmachine.com