- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

UTR6180-702/UTR9000EF/TOP11B/Godart 8001

-

Brand Name:

-

yisun

-

Material:

-

resin

-

Product name:

-

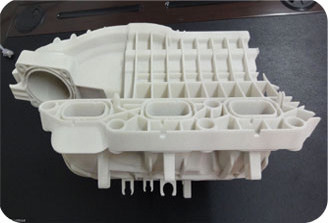

Custom 3d Printer Rapid Prototype Service

-

Process:

-

Polish

-

Color:

-

Customized Color

-

Service:

-

Cutomized

-

Surface treatment:

-

Smooth

-

Drawing Format:

-

IGS STP STL

-

Equipment:

-

3D Printer

-

Size:

-

Customized Sizes Acceptable

-

Quality control:

-

100% Inspection Berore Shipment

Quick Details

-

CNC Machining or Not:

-

Not CNC Machining

-

Material Capabilities:

-

Aluminum, Stainless steel, ABS

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

UTR6180-702/UTR9000EF/TOP11B/Godart 8001

-

Brand Name:

-

yisun

-

Material:

-

resin

-

Product name:

-

Custom 3d Printer Rapid Prototype Service

-

Process:

-

Polish

-

Color:

-

Customized Color

-

Service:

-

Cutomized

-

Surface treatment:

-

Smooth

-

Drawing Format:

-

IGS STP STL

-

Equipment:

-

3D Printer

-

Size:

-

Customized Sizes Acceptable

-

Quality control:

-

100% Inspection Berore Shipment

Essential Details

|

CNC Machining or Not

|

Not CNC Machining

|

OEM:

|

Accepted

|

|

Micro Machining or Not

|

Micro Machining

|

MOQ

|

1 pcs

|

|

Brand Name

|

YIsun

|

Toranrance:

|

±0.1mm

|

|

Type:

|

Laser Machining, Other Machining Services, Rapid Prototying

|

Color

|

Can be customized

|

|

Material Capabilities:

|

Resin, Nylon, ABS Plastic, Arcylic, Steel、Red Wax

|

Files format

|

3dm&igs&stp&stl

|

|

Surface treatment

|

Polish、Spray paint、Deburring, Sandblasting、etc

|

Lead time

|

1-3 days

|

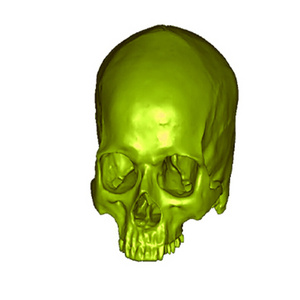

Introduction to 3D Printing

Plastic(ABS&PLA)

Environmentally friendly and durable entry-level material ,

Single molding volume are about to 1100*860*880MM,

Low precision(Not higher than 0.2mm),

Commonly

used to make prototypes of mechanical parts,

General design requirements can not have too much cantilever structure。

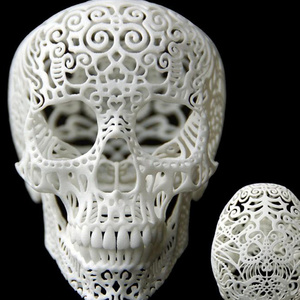

Photosensitive resin

Laser cured resin,

High precision,

Clear boundarie,

Smooth surface .

Materials available in limited primary colors,

Strong printing ability,

Capable of producing translucent and transparent effects .

Nlyon with high strength and high tenacity

More comprehensive 、

Multipurpose

Less design restrictions ,

No need to consider supporting structures ,

One-piece molding can be achieved if your moving parts and mating parts are properly designed;

High material strength

Have a certain degree of flexibility,

It can produce a functional end product,

Including various complex designs .

Metal(Aluminum&Iron&Titanium)

Metal printing is achieved by laser sintering metal powder,

Rough surface of machined finished products,

However, after post-processing, engineering metal structural parts can be achieved,

Finished surface polishing effect is good.

-E

conomy

、High-precision 、Portable

High-precision

Durable

Strong functionality

1、Perfect molding effect

Excellent details

-Good external wall , ;

-Smooth surface ,Integral molding without disassemb ;

-Rich and obvious details;

-Sharp edges andcorners,obvious ;

-High-precision

-Produced by high-functional materials which used by Multi-disciplinary;

Good external wall

Smooth surface

Excellent details

Excellent good quality assurance

accurates

capacity and high efficiency

-Mature laser printing technology, efficient production process and guaranteed accuracy;

-

The printing process is convenient and easy to operate,

and it can meet mass production in a single time;

-

The support structure is manually removed in the post-processing stage, and the polishing ensures the quality

of the finished product;

-

Laser equipment is regularly inspected and maintained

to maintain stable performance and meet customer accuracy requirements.

-

The accuracy of the material forming product is

effectively guaranteed, and it can be directly put into

use as a product;

-

The printed product can fully reflect the problems in

the product concept design, supplemented by efficient

sales service, and shorten the product design and development cycle through rapid communication;

-

Industry and trade integration, excellent technology

and economic and trade strength are not afraid of peer comparison.

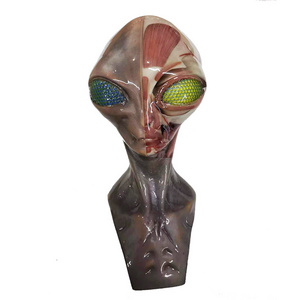

Medical

Industrure hand modeling

Architecture

Architecture

Jewellery

3D printing and industry

3D rapid prototyping technology can save time and cost compared with traditional prototype making process,

Its cost is about 20%~35% of the traditional processing method,

Print samples can be more accurates which means It is suitable for making models with complex structures,

It makes your design ideas and product functions more vivid and intuitive,

It is easier for you to find and solve product problems, thereby further shortening the product design cycle and responding to the market faster,

3D rapid prototyping enables cost reduction,and it is more conducive to enhancing the core competitiveness of enterprises.

Auto industry

Technology products

Aerospace industry

Power Engineering

3D reverse engineering makes the 3D molding process more

widely used in automotive design.

widely used in automotive design.

3D printing technology can shorten the product cycle, and it is beneficial for enterprises to occupy the related product market first;

Application of Aircraft Reverse Engineering.

Manufacturing procedures can

be better controlled to

maintain high manufacturing

accuracy.

maintain high manufacturing

accuracy.

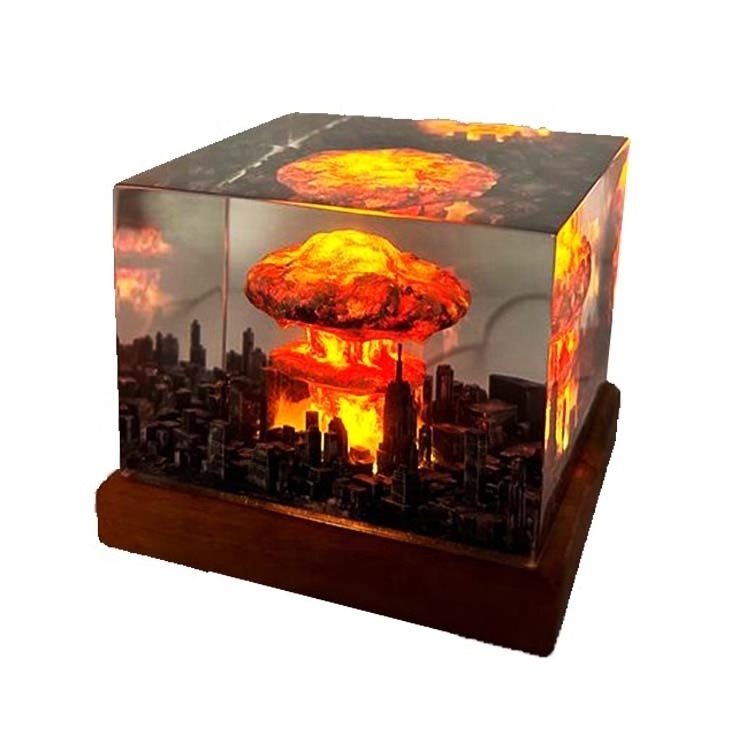

3D printing and creativity

3D rapid prototyping technology can save time and cost compared with traditional prototype making process,Its cost is about 20%~35% of the traditional processing method,Print samples can be more accurates which means It is suitable for making models with complex structures,It makes your design ideas and product functions more vivid and intuitive,It is easier for you to find and solve product problems, thereby further shortening the product design cycle and responding to the market faster,3D rapid prototyping enables cost reduction,and it is more conducive to enhancing the core competitiveness of enterprises.

Art design

Toy design

Doll design Heritage design

3D reverse engineering makes

the 3D molding process more

widely used in automotive design.

Technology products .

Application

of Aircraft

Reverse

Engineering.

Manufacturing procedures

can be

better controlled to

maintain high manufacturing

accuracy.

Supply Ability

There are a total of 200 industrial-grade 3D printers in the two factories to ensure 24-hour uninterrupted production and supply.

9000 Piece/Pieces per Month

Description of production service process

1.Inquiry

When inquiring, customers can first consult the price through the relevant commodity links, or upload the model drawing files that

need to be customized according to the prescribed file format to negotiate the quotation.Waiting for Alibaba sales reply.

need to be customized according to the prescribed file format to negotiate the quotation.Waiting for Alibaba sales reply.

2.Pricing negotiation

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes.

producing PET plastic containers and bottles in all shapes.

3.Put into production.

When the price negotiation is finalizedSales will make a list according to your request

The list includes the following:Raw materials/Production Process/Production requirements/Request color/Shipment delivery date/

Finished material.

Drafting of credit guarantee orders,Confirm order and put into production

The list includes the following:Raw materials/Production Process/Production requirements/Request color/Shipment delivery date/

Finished material.

Drafting of credit guarantee orders,Confirm order and put into production

4.Packing&Delivery

Sales will take pictures of the finished product before packing and shipping to ensure that the product is in good condition.

Transfer the goods to the courier or freight port for transportation.

Transfer the goods to the courier or freight port for transportation.

5.Receiving & After-sales service

After receiving the product, the customer confirms whether it meets the requirements, and the product that does not meet the

requirements can submit a redo application through the relevant sales negotiation, and we will arrange free reproduction.If the

product satisfies you, please settle the final payment and attach a product evaluation.

PS:If the quality problem of the product is caused by the problem of the customer's drawing, the cost of re-production needs to be renegotiated.

requirements can submit a redo application through the relevant sales negotiation, and we will arrange free reproduction.If the

product satisfies you, please settle the final payment and attach a product evaluation.

PS:If the quality problem of the product is caused by the problem of the customer's drawing, the cost of re-production needs to be renegotiated.

Hot Searches