- Product Details

- {{item.text}}

Quick Details

-

Application:

-

exterior wall plaster fence

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Meirun

-

Dimension(L*W*H):

-

1600x2500x1500mm

-

Weight:

-

800 KG

-

Power:

-

3

-

Name:

-

fiberglass mesh weave making machine

-

Function:

-

fence

-

Speed:

-

60-90RPM

Quick Details

-

Type:

-

Water Jet Loom

-

Production Capacity:

-

30-80 m2/h

-

Marketing Type:

-

New Product 2023

-

Application:

-

exterior wall plaster fence

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Meirun

-

Dimension(L*W*H):

-

1600x2500x1500mm

-

Weight:

-

800 KG

-

Power:

-

3

-

Name:

-

fiberglass mesh weave making machine

-

Function:

-

fence

-

Speed:

-

60-90RPM

Product Description

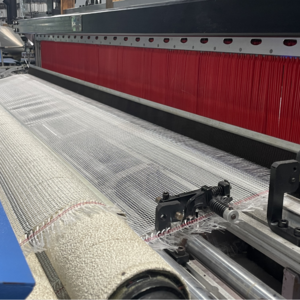

Automatic exterior wall plaster fiberglass mesh weave machine

Fiberglass wire mesh production line consists of warping machine,weaving machine and coating machine.

Weave machine

Specification

|

Machine name

|

Fiberglass wire mesh weave making machine

|

|

Width of products |

1000mm |

|

Mesh size

|

3*3—10*10

|

|

Power

|

0.8 KW

|

|

Dimension

|

1600x2500x1500mm

|

|

Speed

|

150-180rpm

|

Machine width have one meter and 1.5 meter and 2 meter.Can produce as per customer requirement .

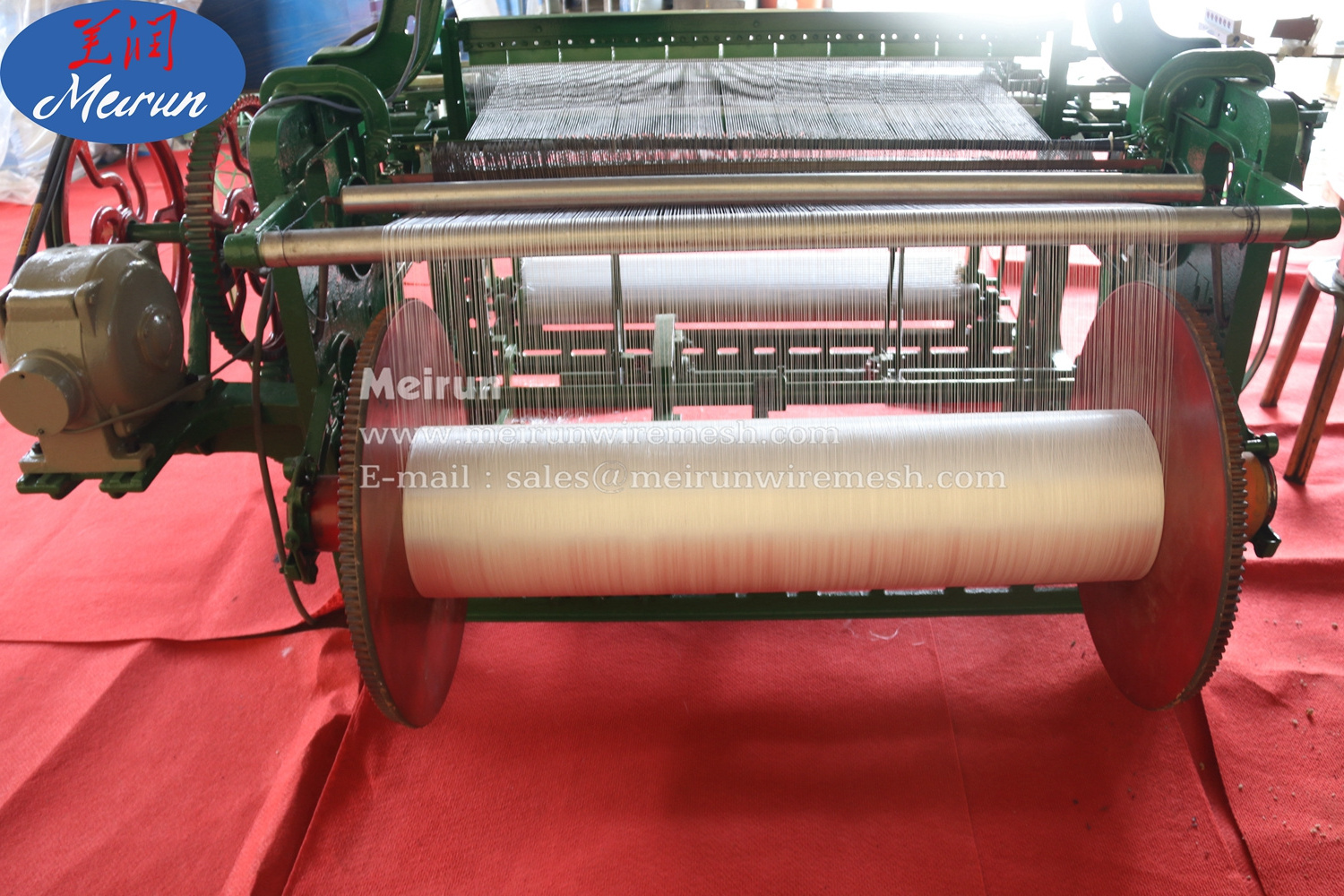

Warping machine

The warping machine include the yarn shelf and main machine,which sorts the yarn to the beam for the weaving mesh.The equipment is controlled by two stages of transmission and tension. The speed is closed and the speed is controlled by constant speed. The two rolls are used to press the shaft surface synchronously, so that the surface of the disc is smoother, tighter, the tension of the single yarn is more uniform, and none yarn broken and loosened during weaving. Infrared ray control,when yarn is broken,the machine will stop automatically.

The warping machine include the yarn shelf and main machine,which sorts the yarn to the beam for the weaving mesh.The equipment is controlled by two stages of transmission and tension. The speed is closed and the speed is controlled by constant speed. The two rolls are used to press the shaft surface synchronously, so that the surface of the disc is smoother, tighter, the tension of the single yarn is more uniform, and none yarn broken and loosened during weaving. Infrared ray control,when yarn is broken,the machine will stop automatically.

Coating making machine

The coating machine produced by our company has two kind:oil heating and electric heating, which can be customized according to customers' needs.Machine include:coating part,drying part and rolling up parts.

This machine is suitable for the processing grinding wheel mesh and the fiberglass mesh with a width of 2m or less, so that the process of gluing, drying, solidifying and winding of the fiberglass mesh is formed once, and the fiberglass mesh after molding is formed. The glue spread evenly, amount of spread suitable, no displacement, and rewinding is very smooth..

This machine is suitable for the processing grinding wheel mesh and the fiberglass mesh with a width of 2m or less, so that the process of gluing, drying, solidifying and winding of the fiberglass mesh is formed once, and the fiberglass mesh after molding is formed. The glue spread evenly, amount of spread suitable, no displacement, and rewinding is very smooth..

Wire rack

Packing & Delivery

Hot Searches