- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

JIA

-

Weight (KG):

-

8000 KG

-

Applicable Industries:

-

Rubber

-

Type:

-

Open Mixing Mill

-

After-sales Service Provided:

-

Engineers

-

Application:

-

Rubber

-

After Warranty Service:

-

Repair Service

-

Name:

-

Rubber Open Roll Mill

-

Function:

-

Compound Mixing

-

Keywords:

-

Silicone rubber Two Roll Mill

-

Mixed capacity:

-

18-35/Batch

-

Gearbox:

-

Hard Gear Reducer

-

Cooling:

-

normal cool water

Quick Details

-

Diameter of Roll(mm):

-

400 mm

-

Length of Roll(mm):

-

1010 mm

-

Cooling Mode:

-

water

-

Place of Origin:

-

JIA

-

Weight (KG):

-

8000 KG

-

Applicable Industries:

-

Rubber

-

Type:

-

Open Mixing Mill

-

After-sales Service Provided:

-

Engineers

-

Application:

-

Rubber

-

After Warranty Service:

-

Repair Service

-

Name:

-

Rubber Open Roll Mill

-

Function:

-

Compound Mixing

-

Keywords:

-

Silicone rubber Two Roll Mill

-

Mixed capacity:

-

18-35/Batch

-

Gearbox:

-

Hard Gear Reducer

-

Cooling:

-

normal cool water

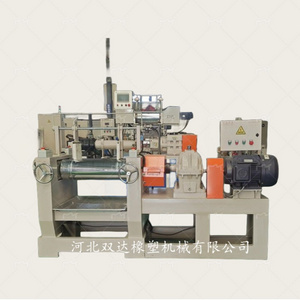

Two Rollers Open Rubber Mixing Mill silicone rubber mixing Mill two roll rubber sheet Open Mill

Application:

This 2 roller open mixing mill ensures the perfect and uniform blending of natural and synthetic rubber with other raw materials. The open mixing mill can mixall the raw materials to the desired specifications.

Structural Features :

1. This open mixing mill can be equipped with hydraulic or mechanical device which can automatically make the rubber material be mixed over and over again. So the labor intensity and mixing time can be reduced greatly.

2. The open mixing mill speed reducer is planetary speed reducer, it is low noise, high efficiency, good transfer effect,

3. To ensure the safety of staff and equipment, we install convenient button for emergency.

4. All the open mixing mills we provide to you are checked after 3-7 hours non-stop full load operation, perfect quality and low noise. Customers can use them immediately after installation.

| Model | XK-160 | XK-250 | XK-360 | XK-400 | XK-450 | XK-550 |

| working diameter of rolls(mm) | 160 | 250 | 360 | 400 | 450 | 550 |

| working length of rolls(mm) | 320 | 620 | 900 | 1000 | 1200 | 1500 |

| linear speed of front roll(m/min) | 8 | 14.9 | 17.4 | 19.3 | 24.5 | 27.2 |

| linear speed ratio | 1:1.35 | 1:1.7 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.29 |

| max roll gap(mm) | 10 | 10 | 10 | 10 | 15 | 15 |

| gap regulating mode | manual | manual | manual | manual | manual or electric | manual or electric |

| batch capacity(kg/batch) | 1-2 | 10-15 | 20-25 | 25-35 | 25-50 | 50-60 |

| main motor power(kw) | 7.5 | 18 | 30 | 37 | 55 | 90/110 |

| speed reducer | worm-gear | ordinary or hardend-gear | ordinary or hardend-gear | ordinary or hardend-gear | ordinary or hardend | ordinary or hardend |

| overall size(mm) | 1080x796x1415 | 3400x1350x1500 | 3940x1780x1740 | 4250x1850x1870 | 5200x2380x1770 | 6260x2330x1750 |

| weight(kg) | 1100 | 3500 | 5670 | 7600 | 13000 | 20000 |

16" Two Rollers Open Mill machine for Saudi Arabic customer

1. If needs, we 'd like to cooperate closely with our dear customers on the formulas, producing procedure proposals, raw materials, packages, electricity, water, gas/air and layout floor plan discussing in full details.

2. Supply the Instructions on manuals of the Operation and Maintainance;

3. 24 hours on line serice to guide or instruct on the installation, commissioning and operation properly;

4. Service at project site if available.

5. Spare parts supply as best convinience for purchasers.