- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

COMENS

-

Model Number:

-

Flexibond 8265/8200

-

Type:

-

artificial grass polyurethane glue

-

Material:

-

Organic Polyurethane

-

Characteristic:

-

Weatherability

-

Application:

-

Synthetic Turf

-

Uses:

-

Artificial Turf Installation

-

Color:

-

Green

-

OEM:

-

Yes

-

Solvent:

-

Free Solvent

-

Weather Resistant:

-

Very Good

-

Certificate:

-

SGS, ISO

Quick Details

-

CAS No.:

-

63148-52-7

-

Other Names:

-

Turf Adhesive

-

MF:

-

-C3H8N2O-

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

COMENS

-

Model Number:

-

Flexibond 8265/8200

-

Type:

-

artificial grass polyurethane glue

-

Material:

-

Organic Polyurethane

-

Characteristic:

-

Weatherability

-

Application:

-

Synthetic Turf

-

Uses:

-

Artificial Turf Installation

-

Color:

-

Green

-

OEM:

-

Yes

-

Solvent:

-

Free Solvent

-

Weather Resistant:

-

Very Good

-

Certificate:

-

SGS, ISO

Flexibond 8265/8200 Polyurethane Adhesive for Bonding Jointing Strips of Synthetic Grass Sheets

Description

Flexibond 8265/8200 is a two-component polyurethane adhesive which is used for bonding jointing

strips between synthetic grass sheets.

Characteristics

(1) No solvent, environmental friendly

(2) Uniform paste, easy to use

(3) Good adhesion and elasticity

(4) Excellent weather resistance

Application

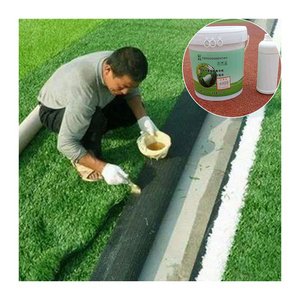

(1) Preparation

Substrates Preparation

According to the synthetic grass usage, substrates must be prepared according to current regulations and standards.

Synthetic Grass Preparation

Unroll and spread out the synthetic grass for several hours before starting installation to allow internal tension caused by the packaging to be reduced.

Adhesive Preparation

Empty barrel for mixing the adhesive: Must be clean and dry.

Mixing tool: Stick for mixing manually or electric mixer.

Electronic scale.

(2) Applying Process

Flexibond 8265/Flexibond 8200=9:1 (by weight)

The resin Flexibond 8265 should be mixed thoroughly before its mixing with the hardener Flexibond 8200. Mix the two components fast till the color is uniform, then mix for 1-2 more minutes.

Apply the adhesive with a notched trowel to achieve a fine appearance and effect.

Use up the mixer as soon as possible before its pot life.

(3) Pressing

Bond synthetic grass joint strips and press within adhesive open time, or the adhesion effect will be affected. Increase the pressure as high as possible with affecting the material forming.

(4) Clean

Recommended Cleaner: dichloromethane, ethyl acetate.

Packaging

Resin: 9kg/barrel

Hardener: 1kg/barrel

The packaging can be adjusted according to customer's requirement.

Storage and Shelf Life

The product remains stable for 12 months (component A), 6 months (component B) if stored in its original sealed container, under shady and ventilated condition, avoiding direct sunlight and rain.

Recommended storage temperature: 0-30ºC.

Technical Data Sheet

| Flexibond 8265 | |||

| 1 | Flexibond 8265 | Flexibond 8201 | |

| 2 | Curing mechanism | Poly addition | |

| 3 | Color | Green (can be adjusted) | Brown |

| 4 | Color after mixing | Green (can be adjusted) | |

| 5 | Viscosity | 100000-150000mpa.s (Brookfield – RVT 7/20) | 200-250mpa.s (Brookfield – RVT 2/20) |

| 6 | Viscosity (after mixing) | 50000-100000mpa.s(Brookfield–RVT7/20) | |

| 7 | Mixing ratio (by weight) | 9 | 1 |

| 8 | Solid content | 100% | 100% |

| 9 | Pot life | 30-50 mins | |

| 10 | Open time | 40-60 mins | |

| 11 | Initial cure time | 2 hours | |

| 12 | Set to light foot traffic | 12 hours | |

| 13 | Recommended working temperature | 0℃-30℃ | |

| 14 | Shear strength (EN 12228-EN13744) | >1500N/100mm | |

| 15 | Peel strength (EN 12228-EN13744) | >100N/100mm | |

| 16 | Shelf life (unopened below 25℃) | 12 months | 6 months |

FAQ

1.Are you manufacturer?

Yes. Our company-COMENS, is the only and the largest company producing polyurethane sealant in China. We have three factories in China-two in Beijing and one in Nantong, Jiangsu.

2.Do you accept Private Label?

Yes. We can do OEM for customers.

3.Can I get a sample before order?

Of course. Generally, we provide 1-5 pieces free samples for you test and the courier fee be born by customers. Thank you for your understanding.

4.How to get samples from your company?

Generally, we send samples by TNT, UPS, FedEx.

5.How long you will finish my order?

It is depend on your order quantity. Generally, we just need 5 days to produce 10000 pieces, 600ml sausage after receive your payment.

6. Can I visit to your factory?

Welcome. Please let me know your trip plan, we would like pick you up and book hotel for you.

7.How to contact you?

Welcome to contact us online in Trade manger, SKYPE(xu.ruofei1), WhatsApp (+0086-150 0127 1163),E-mail(xrf(AT)co-mens.com)

8.How to find the suitable polyurethane sealant?

Please let me know your application purpose, substrate, application method and all your requirements. We would like give you a recommendation.