- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year, 12 months

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Nybon

-

Model Number:

-

NYJB-01

-

Product name:

-

Marine Hydraulic Single Anchor Double Drum Mooring Winch

-

Color:

-

Customized

-

Power supply:

-

Hydraulic

-

Hydraulic pump station:

-

Optional

-

Brake:

-

Hand operated

-

Cluth:

-

Include

-

Warping head:

-

Include

-

Lift Speed:

-

Customized

Quick Details

-

Power Source:

-

Hydraulic

-

Application:

-

BOAT

-

Capacity:

-

50-400KN

-

Warranty:

-

1 year, 12 months

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Nybon

-

Model Number:

-

NYJB-01

-

Product name:

-

Marine Hydraulic Single Anchor Double Drum Mooring Winch

-

Color:

-

Customized

-

Power supply:

-

Hydraulic

-

Hydraulic pump station:

-

Optional

-

Brake:

-

Hand operated

-

Cluth:

-

Include

-

Warping head:

-

Include

-

Lift Speed:

-

Customized

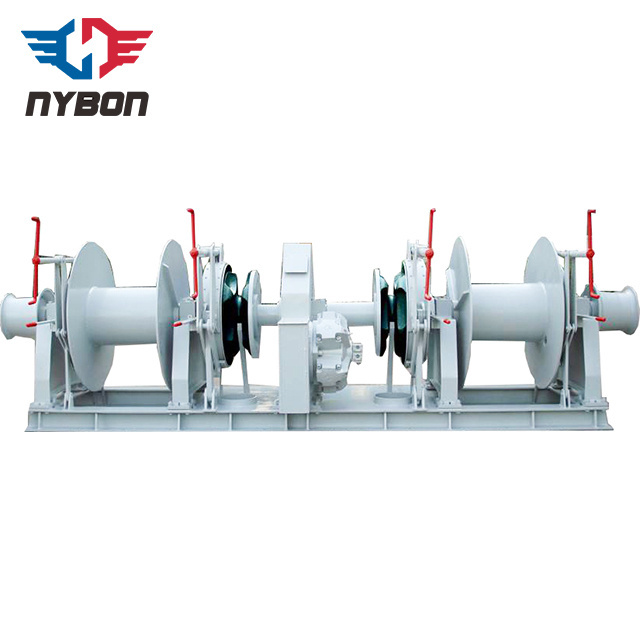

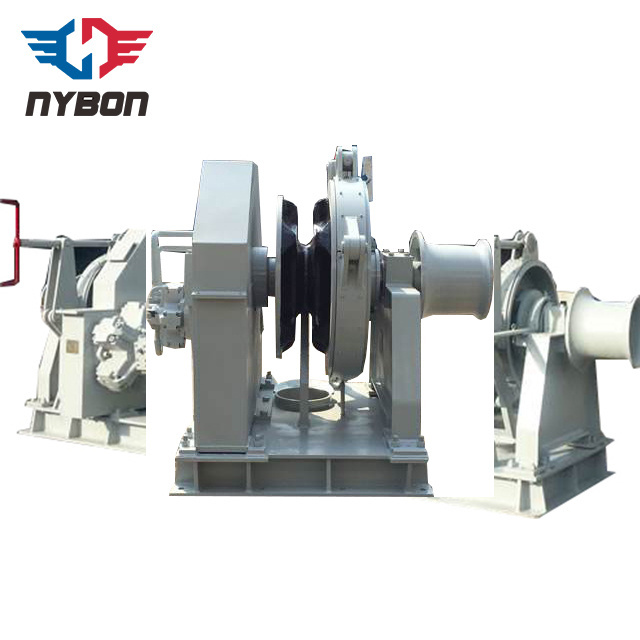

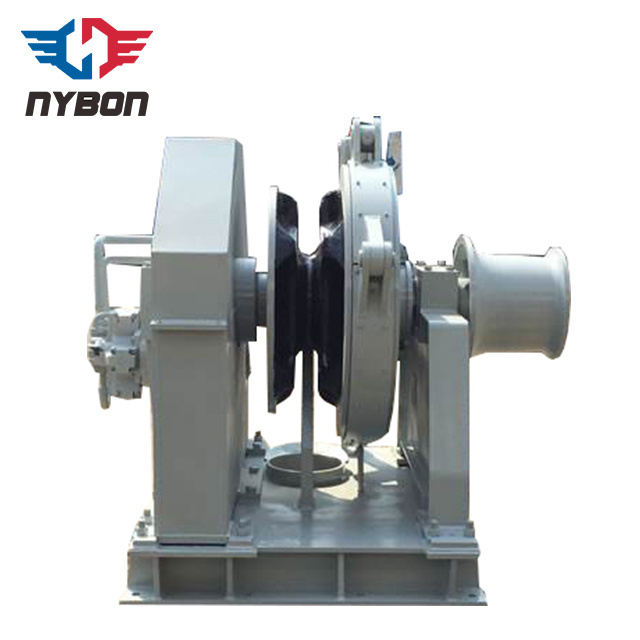

Marine Hydraulic Single Anchor Double Drum Mooring Winch

Marine Hydraulic Single Anchor Double Drum Mooring Winch

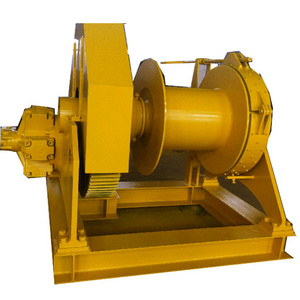

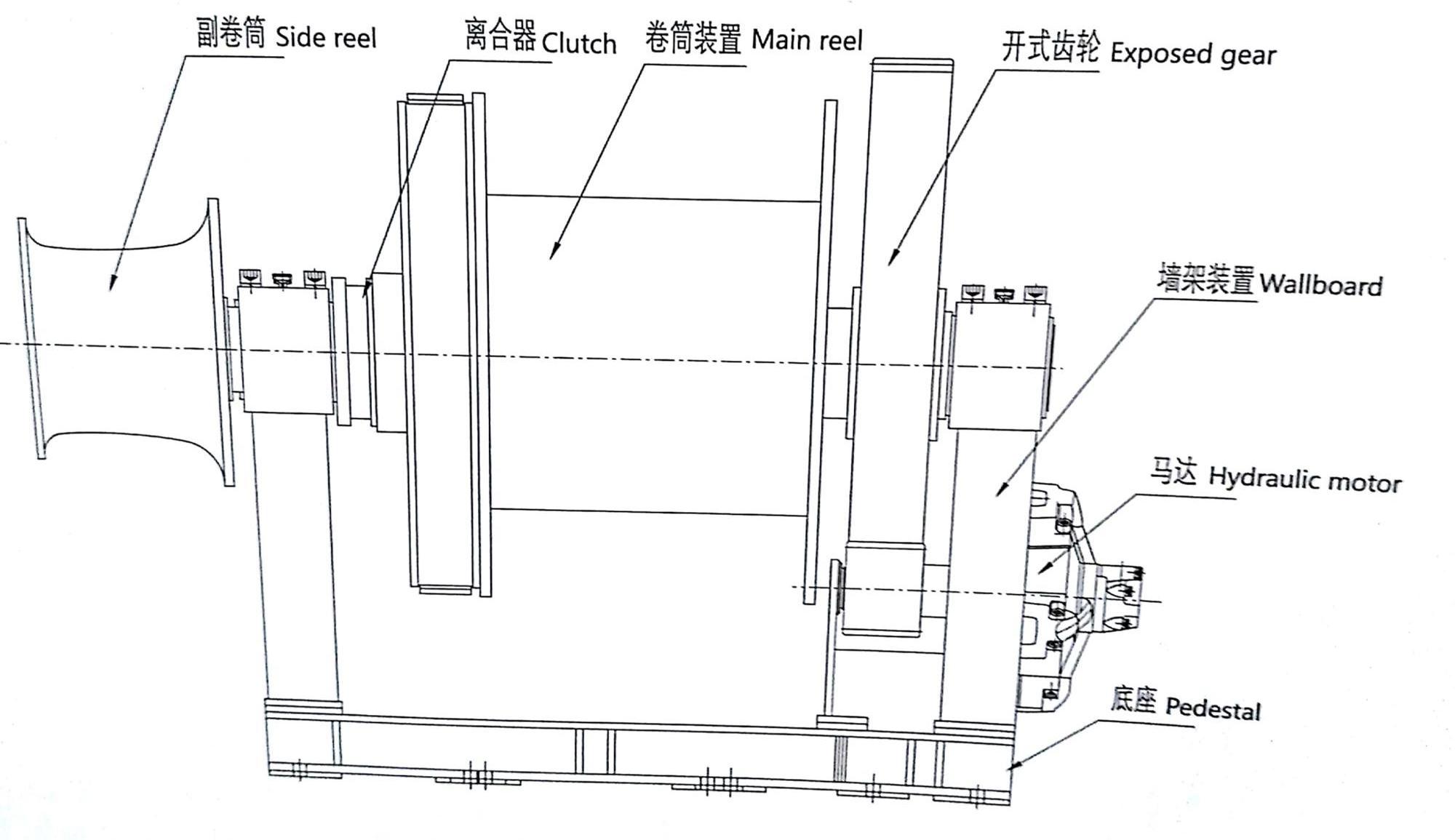

Hydraulic winches are used in a variety of lifting equipment occasions. Types are divided into: built-in hydraulic winch, exposed hydraulic winch, high-speed hydraulic winch, low-speed hydraulic winch, hydraulic winch usually by the hydraulic motor, control valve, gear boxes, rollers, brackets, (clutch) Rope, installation bracket and other combinations.

Some hydraulic winch does not take stand, directly by the hydraulic motor, control valve group, the drum, the end of the shaft and other components, these can be based on customer needs matching, can be widely used in conveyor tensioners, construction machinery Lifting cranes such as truck cranes, crawler cranes, aerial work platforms, forestry cranes, and port vessels such as port cranes, floating cranes, dredgers, crane cranes and davits, as well as heavy lifting equipment Such as oil rigs, offshore oil rigs, rotary drilling rigs for piling machines, rock drills, core drills, hydrostatic piles, and more.

Want to know more, contact me!

Hydraulic winch product features:

1) Only flow restrictors and manifolds are on the outside of the drum. Hydraulic motors and shell to drive devices and other components are hidden in the winch drum, so the axial size is small, compact, beautiful appearance;

2) Starting efficiency and transmission efficiency, low energy consumption, reliable, long service life;

3) low noise during operation;

4) good economic performance.

Send your special needs to us!

Send your special needs to us!

| Model |

Chain dia. (mm) |

Working load (KN) |

Overload pulling force(KN) |

Holding load (KN) |

Nominal speed(m/s) | Drum load(KN) | Nominal speed(m/s) | Rope capacity(m) | Warping load(KN) | |||

| AM2 | AM3 | AM2 | AM3 | AM2 | AM3 | |||||||

| NYZ-17.5 | 17.5 | 13 | 14.6 | 19.5 | 21.9 | 80 | 115 | 0.15 | 10 | 0.17 | φ11*100 | 8 |

| NYZ-19 | 19 | 15.3 | 17.2 | 23 | 25.8 | 95 | 135 | 0.15 | 15 | 0.17 | φ13*100 | 10 |

| NYZ-20 | 20 | 17.9 | 20 | 26.9 | 30 | 110 | 157 | 0.15 | 20 | 0.17 | φ13*100 | 10 |

| NYZ-22 | 22 | 20.6 | 23 | 30.9 | 34.5 | 126 | 180 | 0.15 | 20 | 0.25 | φ15*100 | 15 |

| NYZ-24 | 24 | 24.5 | 27.4 | 36.8 | 41.1 | 149 | 214 | 0.15 | 20 | 0.25 | φ15*100 | 20 |

| NYZ-26 | 26 | 28.7 | 32.1 | 43.1 | 48.2 | 175 | 250 | 0.15 | 20 | 0.17 | φ22*100 | 20 |

| NYZ-28 | 28 | 33.3 | 37.2 | 50 | 55.8 | 202 | 289 | 0.15 | 20 | 0.17 | φ22*100 | 20 |

| NYZ-30 | 30 | 38.3 | 42.8 | 57.5 | 64.2 | 231 | 330 | 0.15 |

30 |

0.17 | φ22*100 | 30 |

| NYZ-32 | 32 | 43.5 | 48.6 | 65.3 | 72.9 | 261 | 374 | 0.15 | 30 | 0.15 | φ20*100 | 30 |

Hydraulic winch variety:

--Pulling hydraulic winch

--Mooring hydraulic winch

--Anchoring hydraulic winch

Hydraulic winch installation:

1, winch installation location and direction, allowing the drum axis as the center, any conversion position.

2, install the base plate bolt hole location installation. Note: The number and size of fixing bolts must comply with the requirements and must not be reduced or replaced with small diameter bolts.

3, winch floor installation, must be fixed and reliable, shall not be bent in use, the installation of the flatness of not more than 0.5mm, otherwise it will affect the smooth operation of the winch,

4, after the winch is installed, the base contact surface should be level and force evenly.

5, to ensure that the vertical axis of the drum and the pulley vertical, vertical axis of the drum and the pulley angle of not more than 1.5 degrees.

6, winch oil control valve should be a spring reset H-type three-way four-way valve, control valve installation location, according to the needs of the operation on the appropriate location.