- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*700*1400

-

Weight:

-

400 KG

-

Marketing Type:

-

New Product 2023

-

Name:

-

Poultry Slaughter Machine

-

Suit for:

-

Chicken Duck Goose Bird

-

Usage:

-

Poultry Defeathering

-

Product name:

-

Fully-featured Slaughter House Machinery

-

Processing:

-

Complete Slaughter Line

-

Feature:

-

Customized Slaughter Line

-

Object:

-

Slaughterhouse Processing Machine

-

Function:

-

Multi-function

-

Capacity:

-

Customised

-

Material:

-

304 Stainless Steel

Quick Details

-

Place of Origin:

-

Henan

-

Brand Name:

-

RunXiang

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

3500*700*1400

-

Weight:

-

400 KG

-

Marketing Type:

-

New Product 2023

-

Name:

-

Poultry Slaughter Machine

-

Suit for:

-

Chicken Duck Goose Bird

-

Usage:

-

Poultry Defeathering

-

Product name:

-

Fully-featured Slaughter House Machinery

-

Processing:

-

Complete Slaughter Line

-

Feature:

-

Customized Slaughter Line

-

Object:

-

Slaughterhouse Processing Machine

-

Function:

-

Multi-function

-

Capacity:

-

Customised

-

Material:

-

304 Stainless Steel

Product Description

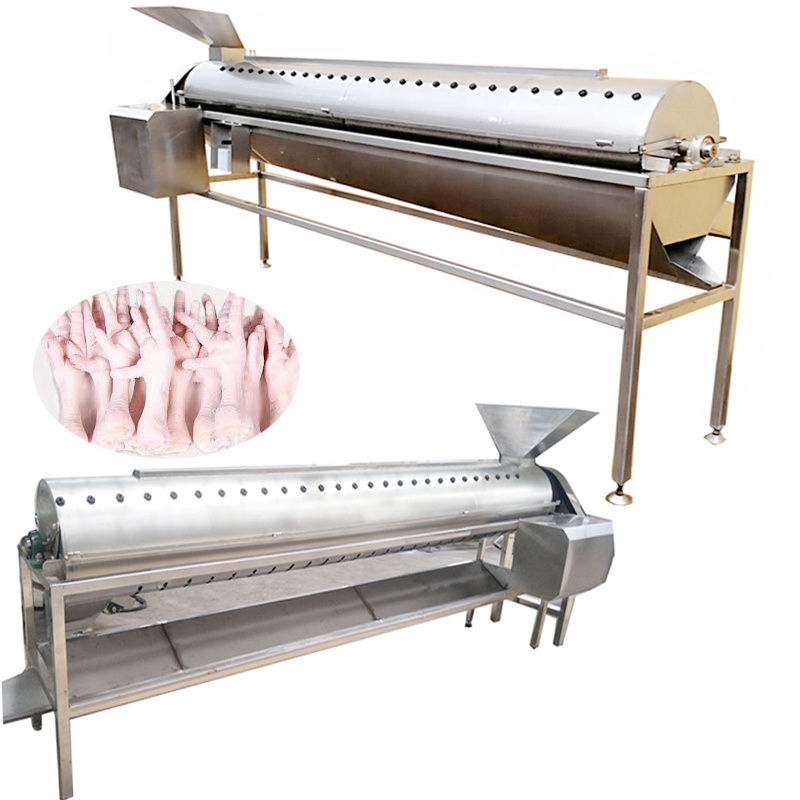

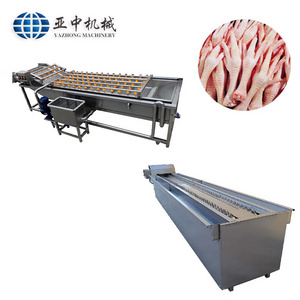

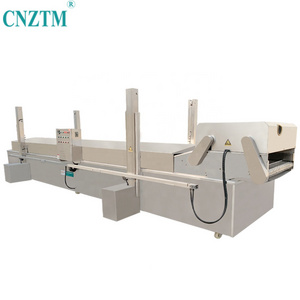

Chicken claw de-yellowing machine and horizontal chicken claw de-yellowing processing line are a kind of equipment to process the chicken feet. The equipment uses spindle fast rotation to drive the rubber rod on the spindle to carry out relative spiral movement, to promote the rotation and advance of the claw in the cylinder. The relative spiral rotation of the rubber rod on the spindle is reversed with the relative spiral of the long groove of the cylinder, and the claw in relative progress is realized. Form reverse force, in order to achieve the beating and kneading of poultry claws, make the yellow skin off the surface of poultry claws, and realize the yellow skin removal of poultry claws. When working, the intake pipe of the upper cylinder is opened to facilitate the shedding of the yellow skin of the poultry claw, and the intake pipe of the lower bracket is opened to facilitate the smooth shedding of the yellow skin of the poultry claw entering the lower bracket.

Fully automatic chicken claw peeling machine is mainly used for removing yellow skin from chicken claws. The speed reducer drives the swing disc to rotate so that the chicken claws spiral in the barrel to complete the peeling work. De-cleaning rate is very high, damage rate is low, clean and sanitary, and efficiency is very high. After the chicken feet are put into the barrel, the reducer drives the disc to rotate, which makes the chicken feet spiral in the barrel of

the professional chicken feet peeling machine. The rotating disc constantly turns the chicken feet and rubs the chicken feet to peel. Because of the constant collision and friction between the chicken feet on the barrel wall of the chicken feet peeling machine, the peeling efficiency is higher. With the special design of the peeling principle, the peeling effect is clean and the output is large.

the professional chicken feet peeling machine. The rotating disc constantly turns the chicken feet and rubs the chicken feet to peel. Because of the constant collision and friction between the chicken feet on the barrel wall of the chicken feet peeling machine, the peeling efficiency is higher. With the special design of the peeling principle, the peeling effect is clean and the output is large.

There is a layer of yellow cutin on the surface of chicken feet and feet, such as poultry. This layer needs to be blanched by a blanching machine first, then peeled by a chicken feet peeler. Structure Features the device is all made of stainless steel ,with the advantage of reliable performance ,easy to use ,low rate of defective production ,the continuous removal of claw skin ,high production officiency and so on

First of all, the use of chicken feet peeling machine can greatly improve production efficiency. The traditional manual peeling needs to manually remove the skin on the chicken feet one by one, which is cumbersome and inefficient. The chicken claw peeling machine adopts a mechanized method for peeling, which greatly reduces labor costs and time costs, and is quick and convenient to operate.

Secondly, chicken feet peeling machine can ensure the stability of peeling quality. Traditional manual peeling is affected by factors such as the technical level and physical condition of the operator, the quality of peeling is unstable, and problems such as cuts and skin residues are prone to occur. The chicken claw peeling machine can maintain the consistency of peeling quality while ensuring the peeling speed, effectively avoiding the occurrence of the above problems.

In addition, chicken feet peeling machine also has the advantages of saving raw materials and reducing costs. Due to errors and waste in traditional manual peeling, it is difficult to ensure the full utilization of raw materials. The chicken feet peeling machine adopts scientific design and precise operation, which can minimize waste, save raw materials, and reduce production costs.

Finally, the chicken feet peeling machine also has the advantage of improving product quality and hygiene safety. Due to the inevitable human factors in traditional manual peeling, it is difficult to guarantee hygiene safety and product quality. The chicken claw peeling machine can be operated in a sterile environment, effectively preventing bacterial infection and other problems, while ensuring the quality and taste of the product.

Detailed Images

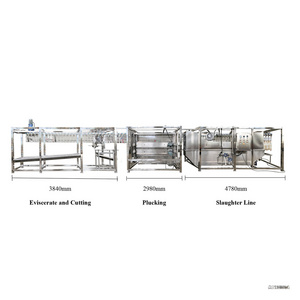

Size Information

|

Model

|

Power(kw)

|

Weight(kg)

|

Size(mm)

|

|

JZ-TPJ

|

5.5

|

400

|

3200*700*1400

|

Best Selling

Company Introduction

Hot Searches