- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

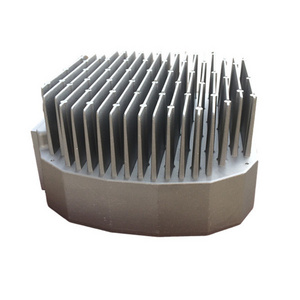

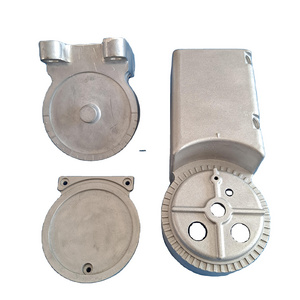

ADC12 A380 a356 t6 Aluminum Die Cast Mould Making Of Customized Parts

-

Material:

-

aluminum adc12, a380, zinc or as customer's requirements

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Surface Finished:

-

Sandblasting, painting, polishing or as customer's requirements

-

Application:

-

Die cast transmission case

-

Certificate:

-

ISO, or as customer's needs

-

Weight:

-

0.01kg~20kg for aluminum die casting alu plate cast

-

Package:

-

Big Plastic Bag Inside,Multilayer Wooden Box outside

-

Delivery time:

-

40-45 days for die cast transmission case

-

Services:

-

Custom metal parts based on your drawings or samples

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Matech

-

Model Number:

-

Transmission Case

-

Product name:

-

ADC12 A380 a356 t6 Aluminum Die Cast Mould Making Of Customized Parts

-

Material:

-

aluminum adc12, a380, zinc or as customer's requirements

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Surface Finished:

-

Sandblasting, painting, polishing or as customer's requirements

-

Application:

-

Die cast transmission case

-

Certificate:

-

ISO, or as customer's needs

-

Weight:

-

0.01kg~20kg for aluminum die casting alu plate cast

-

Package:

-

Big Plastic Bag Inside,Multilayer Wooden Box outside

-

Delivery time:

-

40-45 days for die cast transmission case

-

Services:

-

Custom metal parts based on your drawings or samples

SINCERITY QUALITY COMPETENCE ENTERPRISING

Die casting is a precision casting method that uses high pressure to force molten metal into a metal mold with complex shapes. In 1964, the Japan Die Casting Association defined die casting as "a casting method that presses molten alloy into a precision mold at a high temperature, and mass-produces high precision and excellent casting surface in a short time." The United States calls die casting as Die Casting, while the United Kingdom calls die casting as Pressure Die Casting , and the Japanese term that is most familiar to the general industry in China is called die casting. Castings manufactured by die casting are called die castings. Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys. This process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting, a cold chamber die casting machine or a hot chamber die casting machine is required. The cost of casting equipment and molds is high, so the die casting process is generally only used for mass production of a large number of products. Manufacturing die-cast parts is relatively easy, which generally only requires four main steps, and the individual cost increment is very low. Die casting is particularly suitable for manufacturing a large number of small and medium-sized castings, so die casting is the most widely used one among various casting processes. Compared with other casting technologies, the die-casting surface is flatter and has higher dimensional consistency. Based on the traditional die-casting process, several improved processes were born, including a non-porous die-casting process that reduces casting defects and eliminates pores. It is mainly used for processing zinc, which can reduce waste and increase the yield of direct injection process. There are also new die-casting processes such as the precision die-casting technology and semi-solid die-casting invented by General Dynamics.

General Products Application /Service Area:

We are custom casting aluminum parts based on your drawing or sample. aluminum parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

Product Name

|

Factory Custom Make Motorcycle Cylinder Head Aluminum Die Cast

|

|

Main blank Process

|

Die Casting,

High Pressure Casting etc. |

|

Blanks Tolerance -Casting Tolerance

|

CT4-6 for Die Casting

|

|

Applicable Material for Die casting

|

Aluminum adc12 a380, Zamak 3, Zamak 5, Zamak 7, Zamak 2, Or according to customer requirements

|

|

Casting Blank Size /Dimensions

|

2 mm-1500mm / 0.08inch-60inch , or according to customer requirements

|

|

Applicable Machining Process

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc.

|

|

Machining Tolerance

|

From 0.005mm-0.01mm-0.1mm

|

|

Machined Surface Quality

|

Ra 0.8-Ra3.2 according to customer requirement

|

|

Application

|

Die cast transmission case

|

|

Applicable Finish Surface Treatment

|

Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating,

Finish Painting, as customers request. |

|

Lead Time

|

About 50 days for die cast transmission case

|