- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-plastic pellet production process

-

Voltage:

-

220V/380V

-

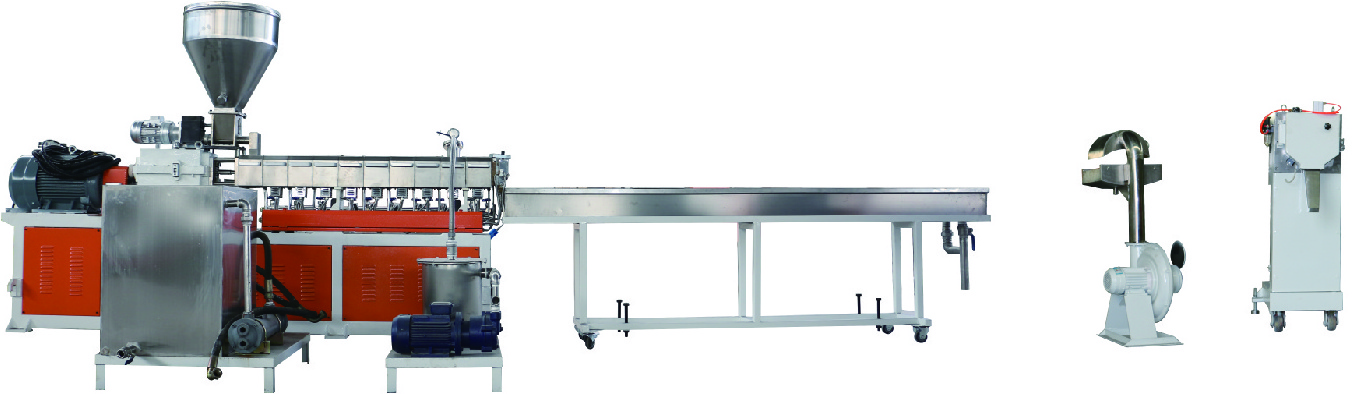

Dimension(L*W*H):

-

8000MM*1200MM*1500MM

-

Power (kW):

-

132

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Depending on Customers

-

Type:

-

granulating machine plastic extruder machine twin screw

-

Certification:

-

CE , ISO9001

-

Name:

-

Extrusion Machine

-

Material:

-

PP PE PET PVC EVA

Quick Details

-

Screw Design:

-

two-stage

-

Screw L/D Ratio:

-

44

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-plastic pellet production process

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

8000MM*1200MM*1500MM

-

Power (kW):

-

132

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Depending on Customers

-

Type:

-

granulating machine plastic extruder machine twin screw

-

Certification:

-

CE , ISO9001

-

Name:

-

Extrusion Machine

-

Material:

-

PP PE PET PVC EVA

FEATURES AT A GLANCE

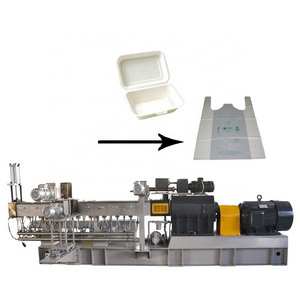

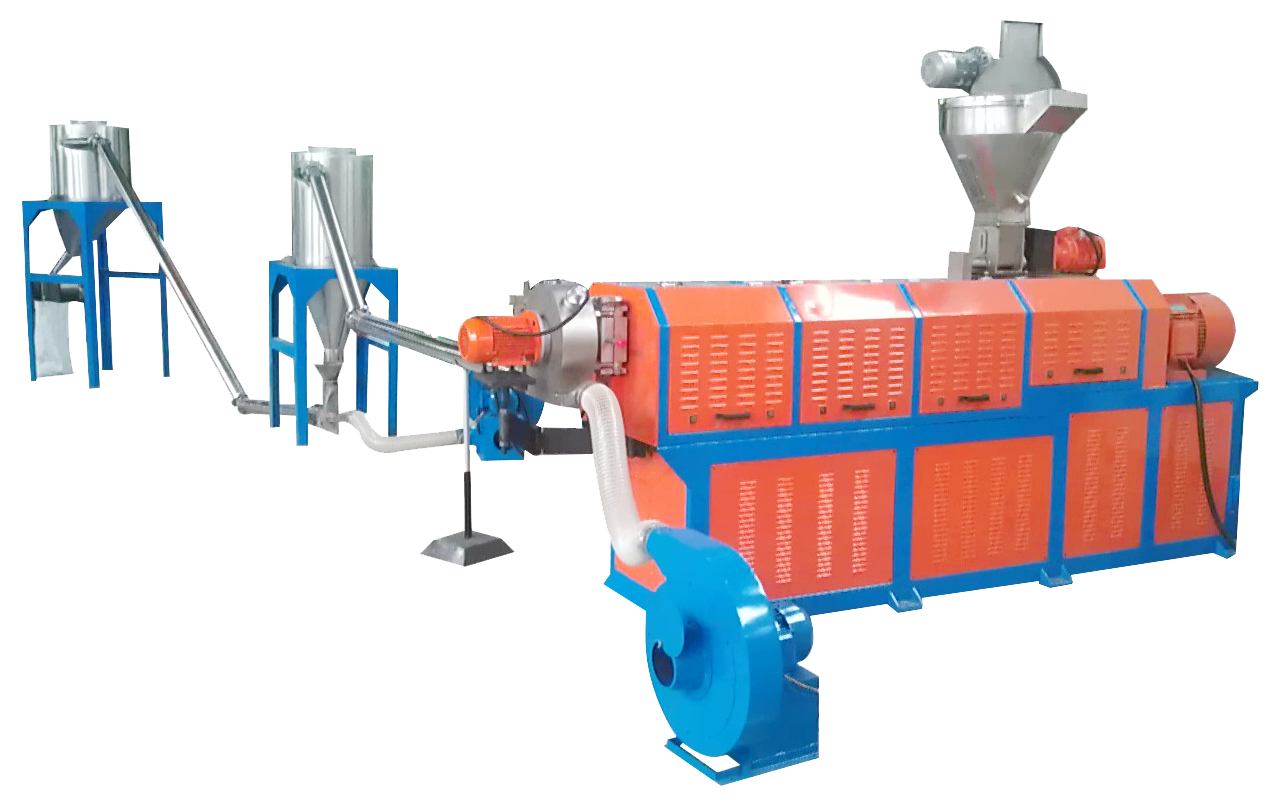

High Torque Plastic Twin Screw Extruder Machines Rubber Plastic Pellets Extruding Machine

Product Overview

We have five different types of pelletizing system.

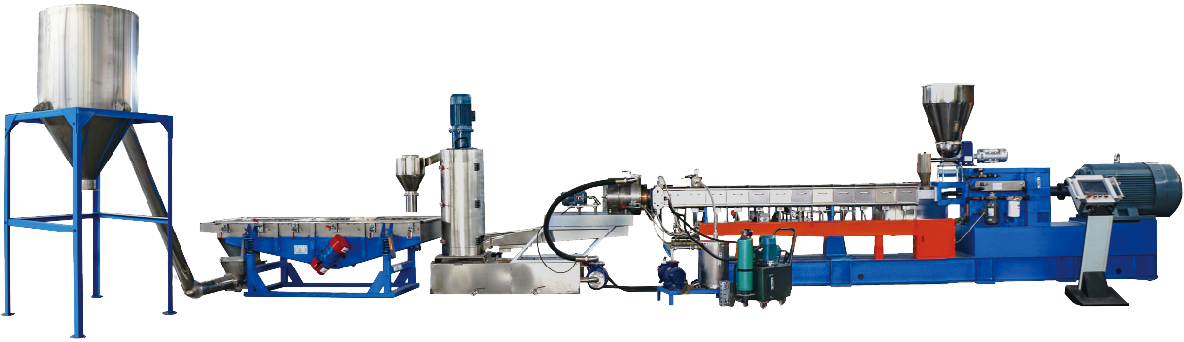

First

is water strand system. The material come out from die head and then through water tank for cooling, then there is a pelletizer to cut the material to be granules.

Second

is water ring system. The material will be cut in the die head, then drop into the water, through water cooling, then come into the Centrifugal dehydrator, remove the moisture. Then through Vibration sieve and silo.

Third

is die face hot cutting system. The material will be also cut in the die head. Then through cyclone, cooling the material.

Fourth

is air cooling strand system. The die head is same as water strand die. Then use conveyor belt and cooling fan to cooling the material, then there is a pelletizer to cut the material to be granules.

Last

is underwater pelletizing system. The die head is under the water, material will be cut in the water and then through Bypass pipe, and drying by the dehydrator.

Different pelletizing system is suitable for different materials.

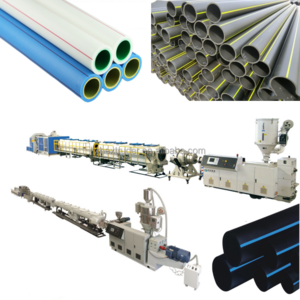

Related products

Application area

PRODUCT CONFIGURATION

Introduction to Twin Screw

GS-mach is a professional plastic,rubber and chemicals ma-chinery researcher,designer and manufacturer with CE&l-SO9001

certificates. Twin screw extruder is widely used. It is suitable for modifi-cation processing and masterbatch production of most

plastic materials. Glass-filled reinforcement: PP, PA, PC, ABS, PPS, PET, PBT+glass fibreCompounding and blending: PC+ABS, PA+ABS,

PP+EPDM, PP+SBSColor master batch: PP, PE, PS, PBT, PET, ABS, EVA+color pigmentIncorporation of fillers: PP, PA, PC, ABS, PPS,

PET,PBT+CaCo3, TALCCompounds for cable and other pelletizing Degassing

Main production of plastic extruders, plastic particles, degradable plastic production lines, including other plastic machinery production.Chemical raw material formula also has research to sell, so contact us, you will learn more!

Hot Searches