- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380/440

-

Dimension(L*W*H):

-

According to capacity

-

Weight:

-

According capacity to

-

Product name:

-

mechanical groundnut oil pressing machine

-

Color:

-

Customer Required

-

Raw material:

-

groundnut/peanut

-

Product:

-

edible groundnut oil

-

Solvent name:

-

n-hexane

-

Oil residues:

-

less than 1%

-

Function:

-

getting oil from groundnut/peanut

-

Material of equipment:

-

stainless steel and carbon steel

-

Package:

-

Wooden Case

-

Shipping:

-

Sea

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Nigeria

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Certification:

-

CE&ISO&BV

Quick Details

-

Production Capacity:

-

98%-100%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Doing

-

Voltage:

-

220/380/440

-

Dimension(L*W*H):

-

According to capacity

-

Weight:

-

According capacity to

-

Product name:

-

mechanical groundnut oil pressing machine

-

Color:

-

Customer Required

-

Raw material:

-

groundnut/peanut

-

Product:

-

edible groundnut oil

-

Solvent name:

-

n-hexane

-

Oil residues:

-

less than 1%

-

Function:

-

getting oil from groundnut/peanut

-

Material of equipment:

-

stainless steel and carbon steel

-

Package:

-

Wooden Case

-

Shipping:

-

Sea

-

After Warranty Service:

-

Video technical support, Online support, Field maintenance and repair service

-

Local Service Location:

-

Nigeria

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Certification:

-

CE&ISO&BV

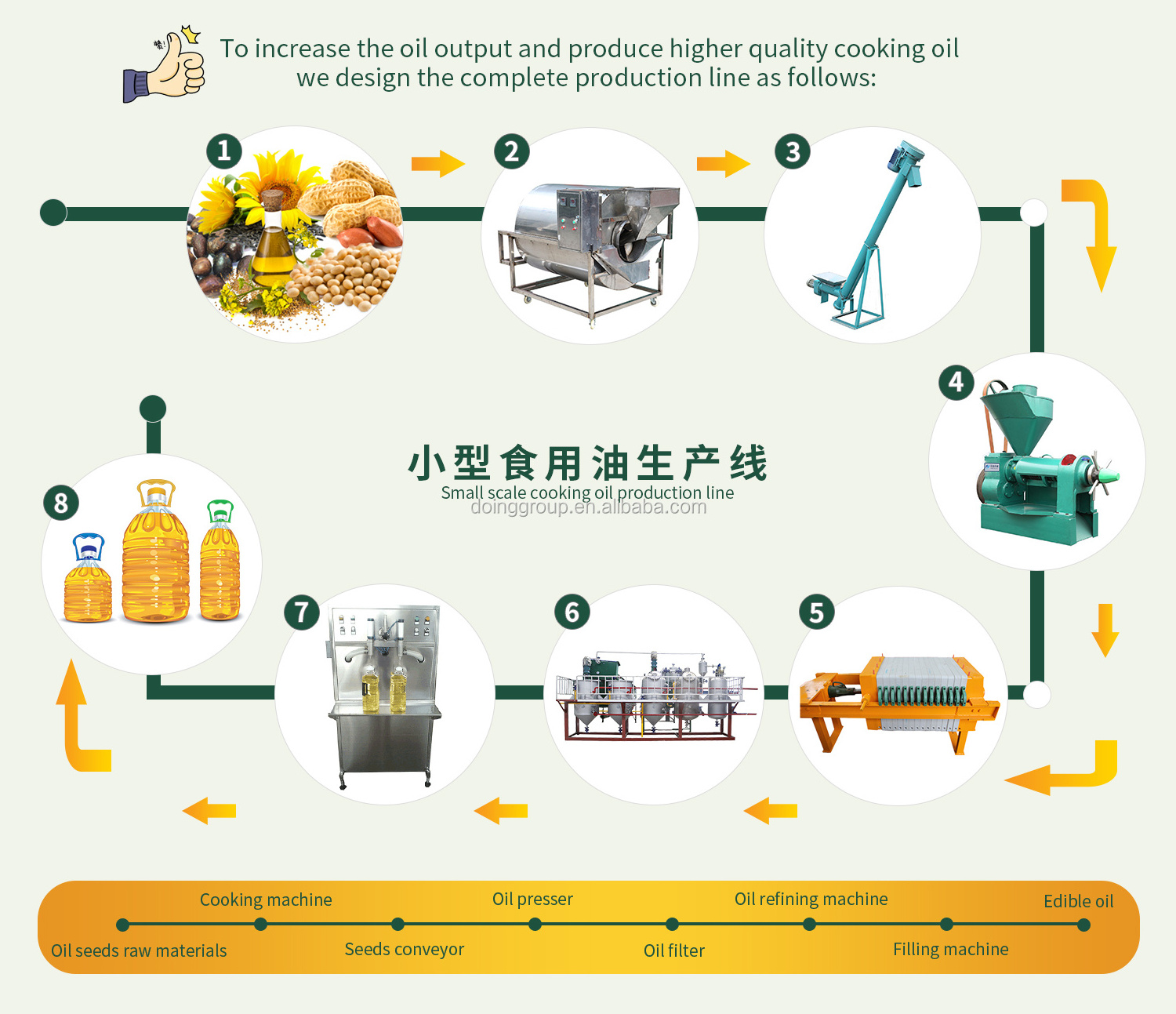

Groundnut oil pressing machine process includes two parts: oil material pretreatment process and groundnut oil pressing process. This is suitable for large scale groundnut oil mill plant.

1. Cleaning section of mechanical groundnut oil pressing machine

The section mainly use magnetic separator, de-stonner and vibrate cleaning sieve to remove metals, small stones, impurities from rice bran.

2. Husking section of mechenical groundnut oil pressing machine

After cleaning, the groundnuts shoul be remove shells by husking machine, because the shells will reduce the oil yield.

3. Crushing section of mechenical groundnut oil pressing machine

The section is a process to make the groundnut become small pieces, easy to press and increase oil yield.

4. Flaking section of mechenical groundnut oil pressing machine

Flaking machine is used to make the groundnut become flakiness, also in order to easy to press, and increase the oil yield.

5. Cooking section of mechenical groundnut oil pressing machine

Cooking machine is mainly used to cook the groundnut, to adjust the temperature and humidity of the groundnut so as to improve extraction efficiency.

6. Pre-pressing section of mechenical groundnut oil pressing machine

Because of the high oil content, groundnut oil should be pre-pressed, and then are sent into groundnut oil solvent extraction plant.

---Solvent extraction machine of groundnut oil solvent extraction plant---

Oil extraction is an advanced oil production craft, now widely applied to oil plants,and it's an organic solvent extraction method,oil is extracted from rice bran by contact(soaking or spraying) of solvent and rice bran.

Groundnut oil solvent extraction process

Fresh Solvent--Cake--Extracting--Wet Meal--Desolventising--Meal--Miscella--Evaporating and stripping--Solvent mixture--Condensing and Recovering--Crude Oil--Solvent Recycling--Refining Workshop.

A. Desolventizing-toasting section

The meal from extractor contains 25-35% solvent, for recovering solvent and getting better meal, solvent can be toasted by heating.High material layer toaster is usually applied to remove solvent from meal as well as dry extracted meal; DTDC desolventizer should be used for extracted rice bran meal.

B. Evaporation and steam-stripping section

the mixed oil will pass through two evaporators to make solvent inside transform into gas , and solvent will be recovered through condensers and reused. These two evaporators are not with same size , the first evaporator is bigger than the second one because there are more solvent inside mixed oil in the beginning . After evaporating, the oil will be pump into the stripping tower. Finally, we will get crude rice bran oil ready for oil refining.

The advantages of grundnut oil solvent extraction plant:

1. high oil yield, low residual oil rate of meal;

2. low labor intensity;

3. good working environment;

4. good meal quality.

---Refining section of groundnut oil making machine---

Brief processes of groundnut oil refining line:

Crude groundnut oil→degumming section→deacidification section→Decolorization section→Deodorization section → Dewaxing & defatting section

A.Crude oil degumming section

Hydrated degumming, mainly is to remove phosphatide inside crude sunflower oil in order to reduce oil loss and improve quality of oil.

B.Alkali refining deacidification section

Alkali refining, using alkali to neutralize free fatty acid with by-product of soapstock, which is used for making soap.

C.Decolorization section

Decoloration using bleaching clay to absorb darker colorant inside crude oil.

D.Deodorization section

Deodorization is using high temperature to remove the impurities with bad smell .