- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HuaNuo

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

10500*900*1200MM

-

Weight:

-

3500 kg

-

Feeding width:

-

500MM

-

Marketing Type:

-

New Product 2022

-

Product name:

-

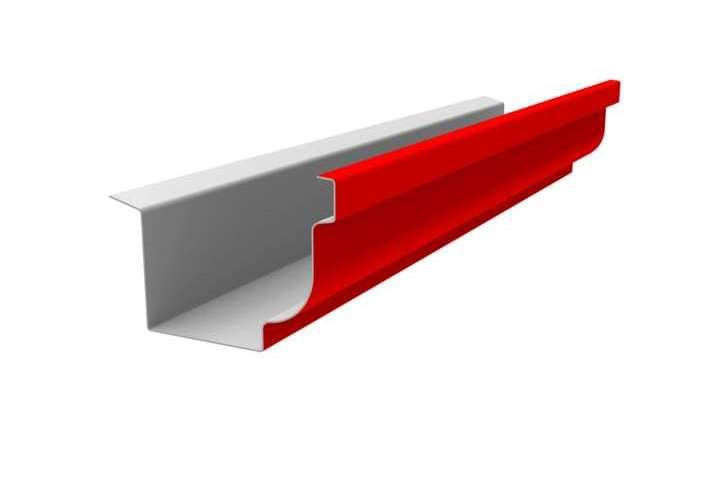

Gutter Roll Forming Machine

-

Usage:

-

Roof Tile Panel

-

Raw material:

-

PPGI PPGL GI GL

-

Control system:

-

PLC(detla) System

-

Shaft material:

-

High Grade No.45 Forged

-

Application:

-

Roofing Industry

-

Certification:

-

ISO CE

-

Function:

-

Wall Panel Forming Machine

-

Decoiler:

-

3T Manual Decoiler

-

Thickness:

-

0.3-0.8mm

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20M/MIN

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HuaNuo

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

10500*900*1200MM

-

Weight:

-

3500 kg

-

Feeding width:

-

500MM

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Gutter Roll Forming Machine

-

Usage:

-

Roof Tile Panel

-

Raw material:

-

PPGI PPGL GI GL

-

Control system:

-

PLC(detla) System

-

Shaft material:

-

High Grade No.45 Forged

-

Application:

-

Roofing Industry

-

Certification:

-

ISO CE

-

Function:

-

Wall Panel Forming Machine

-

Decoiler:

-

3T Manual Decoiler

-

Thickness:

-

0.3-0.8mm

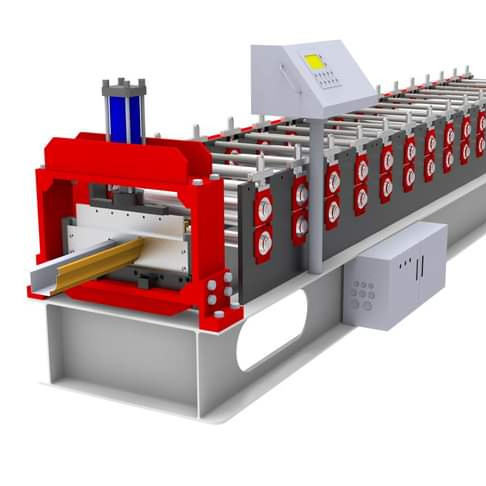

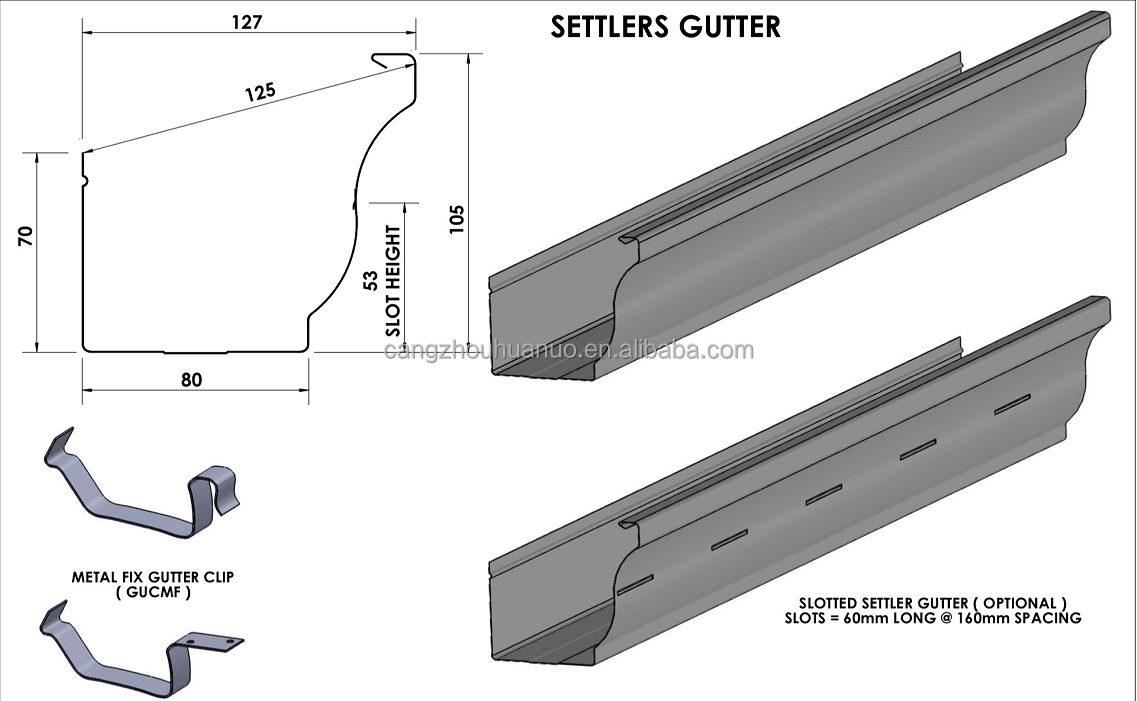

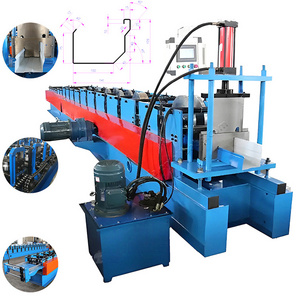

K-Style gutters metal rain gutters roll forming machine

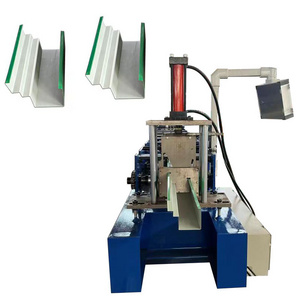

1)machine structure:wall panel structure

2)Main power:5.5KW motor

3)Forming stations:20

4) Way of drive:1.0" single row chain drive

5)Diameter of shaft:70mm

6)Max rolling speed: 12-15m/min

7)Thickness: 0.3-0.8mm galvanized steel or prepainted sheet,G235Mpa

8) Material width:as request

9)Material of roller:polished and coated with chrome, surface with 0.05mm

10)Material of blade mould:Cr12, quenched 58-62℃

11)way of cutting:hydraulic mould cutting(stop to cut)

12)Length cutting tolerance:+/-1.0mm

13)Hydraulic pressure :16Mpa

14)Hydraulic power:5.5kw

15)Computer Control system:PLC control from Taiwan

16)Omron encoder measure the length ,made in Japan

17) Electrical requirement:380V,50Hz,3Ph

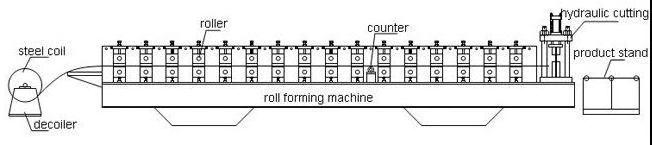

anual De coiler — Roll F orming M achine — Computer Control System — H ydraulic Cutting S ystem — Receive Table & Advantage

The List of materials included in one complete machine set Quotations

| No. | STD material which included in one complete machine set quoted | QTTY(Set) |

| 1 | Manual Decoiler Max 3T | 1 pcs |

| 2 | Main forming Machine | 1 set |

| 3 | PLC Control system & Touch screen | 1 set |

| 4 | Hydraulic Pump Station | 1 set |

| 5 | Post cutter | 1 set |

| 6 | Electric Motor | 1 set |

| 7 | Output Table | 1 set |

1. Quality Control

A. Every parts of machine is examed carefully without any omit.

B. Welcome to our factory to check machine

2. Installation & Training

A. We supply video to teach buyer how to install and operate machine

B. Welcome customers come to our factory, we are glad to teach you face to face.

C. Our technicians could come to customers' factory to install machine

3. After-sale service

A. One year warranty for parts and shipment of parts is free.

B. 24hours*365 days technical support online.

Mr.Jimbo

Cangzhou HuaNuo Cold Bending Machinery Co.,Ltd

West National 104 Road,Botou,Hebei,China,Pd:062150

Mobile/+86-18333779181 ,Ali TM:cn1542543687ablt

Contact us by