- Product Details

- {{item.text}}

Quick Details

-

Power:

-

120~200w

-

Dimension(L*W*H):

-

Depends on the model

-

Weight:

-

Depends on the model

-

Application:

-

envorimental ,chemical wastwater ,food

-

Advantage:

-

consumption saving,low run expense

-

main parts:

-

heater and separator

-

stage of effector:

-

4

-

description:

-

MVR system

-

flow:

-

Falling film,forced circulation,increasing film

-

system includes:

-

MEE,TVR,WHE

-

working pressure:

-

normal,positve pressure,negative pressure

-

Characteristic:

-

reduce steam consumption and cooling media consumption

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kingreat

-

Voltage:

-

220V,380V,440V,480V...

-

Power:

-

120~200w

-

Dimension(L*W*H):

-

Depends on the model

-

Weight:

-

Depends on the model

-

Application:

-

envorimental ,chemical wastwater ,food

-

Advantage:

-

consumption saving,low run expense

-

main parts:

-

heater and separator

-

stage of effector:

-

4

-

description:

-

MVR system

-

flow:

-

Falling film,forced circulation,increasing film

-

system includes:

-

MEE,TVR,WHE

-

working pressure:

-

normal,positve pressure,negative pressure

-

Characteristic:

-

reduce steam consumption and cooling media consumption

-

Certification:

-

ISO

Mechanical vaporization re-compression system, which is called MVR which principle is to compress the second steam generated by evaporator by high efficiency steam compressor; this process transfers electric energy to heating energy and higher the pressure and temperature of second steam. The second steam with higher temperature will be sent to evaporation room to heat the product for evaporation. So the latent heat of vaporization of the second steam can be circularly used. Making use of less energy which is the mechanical energy of compressor blade wheel as the compression heat pump, energy is added into the heating medium and is circularly used in heating process. Under this circumstance, no need to add first steam as heating medium.

Working principle

Compress secondary steam by using steam centrifugal compressor or other steam compression device to make sure its physical properties meet with the requirements for heating steam ; evaporation that uses it as heating steam only requires fresh steam supply when the machine is started. After entering normal operation, there is no need to supply new steam and no (or very little) secondary steam needs condensation. Therefore MVR evaporation substantially cuts down steam demand but consumes more power.

Multi-effect evaporation steam consumption

|

Effective number |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

Steam consumption (t steam/ t water) |

~1.04 |

~0.53 |

~0.36 |

~0.28 |

~0.23 |

~0.19 |

~0.17 |

~0.15 |

Main characteristics

1)Main driven power of MVR evaporation system is electric energy. Electric energy transfer to mechanical energy and improve the quality of second steam which is more economic than produce or purchase fresh steam.

2)Under most of the evaporation process, system no need fresh steam during operation. Only need some steam compensation for pre-heating the raw material when heat energy from product discharged or mother liquid cannot be recycled due to process requirement.

3)No need independent condenser for second steam condensation, so no need circulating cooling water. Water resource and electric energy will be saved.

4)Compared with traditional evaporators, MVR evaporator temperature difference is much smaller, can achieve moderate evaporation, greatly improve product quality and reduce fouling.

5)Evaporation temperature of system can be controlled and very suitable for evaporation an concentration of thermal sensitive product.

6)Lowest energy consumption and operation cost,electricity consumption of one ton water's evaporation is 2.2ks/C.

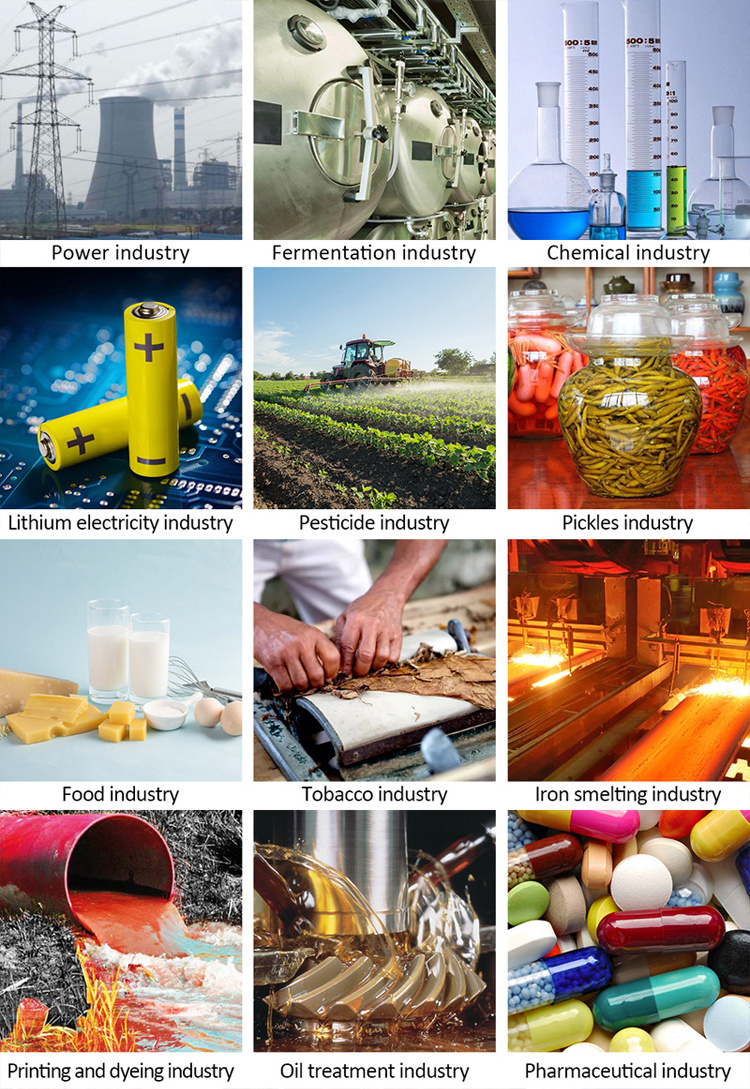

Application

Applied to multiple areas, such as: "zero release" solution for industrial waste water, Evaporation and concentration for process industry, food fermentation (aginomoto, citric acid, starch and sugar), pharmacy (traditional Chinesemedicine preparation, low temperature concentration of western medicine), fine chemical (pesticide, synthetic dyes, organic pigments, paints, spice and essence, cosmetic), chlorine chemical (salt water concentration), seawater desalt and metallurgical industry, etc.

We are one of the world's leading manufacturers of disc centrifuges, decanters, separation systems and marine equipment. We focus on food production, environmental protection, energy recycling, chemistry and marine. Now there are over 150 series of decanter centrifuges and disc separators used both home and abroad.

2. Abundant spare parts in stock are available to provide.

3. Our technicians could be dispatched for overseas service.

4. 7*24 hours technical consultation.

5. Your workers could get trained both in our factory and yours.

6. Routine tracing till the machine work properly will be done timely.

7. We will remind you to do the normal maintenance.

8. Your suggestions or any comments & reflection would be treated in priority.

9. Marketing team will visit you during our visit in your country if you require.

If you come from abroad, air to Shanghai airport, then take bullet train, about 1 hour from Shanghai to Nanjing South Station; if you come from our domestic city, air or train directly to Nanjing, we will pick you up both in the airport and railway station.

2. Can we visit your end user or contact them?

Yes, users are in domestic and abroad, we can provide you the name list, you can go there or contact for more info.

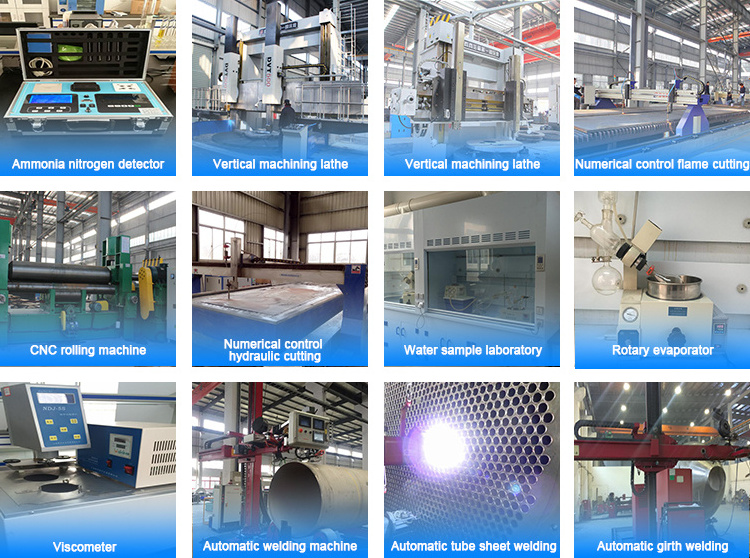

3. How do you protect the quality?

Our factory is a state owned enterprise with more than 100 years experience, strict operation policy is performed, advanced processing machines guarantee the precision of all components, workers with operation license, parts get multiprocessing, transmission & electrical parts are of international famous brand. Series of test and inspection are done in the whole producing stage.

4. Will you dispatch technicians for installation and commissioning?

Yes, we can, we do lots of service, please refer to our after sales part.

5. What is your advantages compared with your competitors?

Quality and experience. We are the top centrifuge supplier in China, our designs and structures are similar to world famous brands.

6. Is your price competitive?

Our price is not the lowest in China as for high quality, but we promise, for the same quality and collocation, our price is the most favourite, for the same price, our quality is definately superior to other brand.

7. Do you have OEM serive? Do you supply the parts?

Yes, we do, as long as you provide us your drawing and detailed requirements.

8. Do you supply second hand centrifuge?

No, we only provide brand new machine.

9. Do you have agent or service center in my country?

We have some partnership in several countries as Indonesia, Brazil, USA, etc. Your are warmly welcomed to work as our agent. At this moment, we have no service center abroad, but we can provide overseas spot and online technical service in time.

10. How can we easily find out the most fit centrifuges?

We have experienced engineer team to help you make the model selection, as long as you provide us the detailed processing material characteristics.

11. What payment mode you accept?

TT, Wester Union and LC at sight.